System and Method for Modeling Signal Flows in Automation Technology Equipment

a technology of automation technology and signal flow, applied in the field of system and method for generating a behavior model for the simulation of an automation system, can solve the problems of high complexity of control software for controlling the components of this known equipment, high complexity of known production-engineering equipment, and easy errors, so as to achieve the maximum possible data consistency, increase user convenience, and facilitate simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

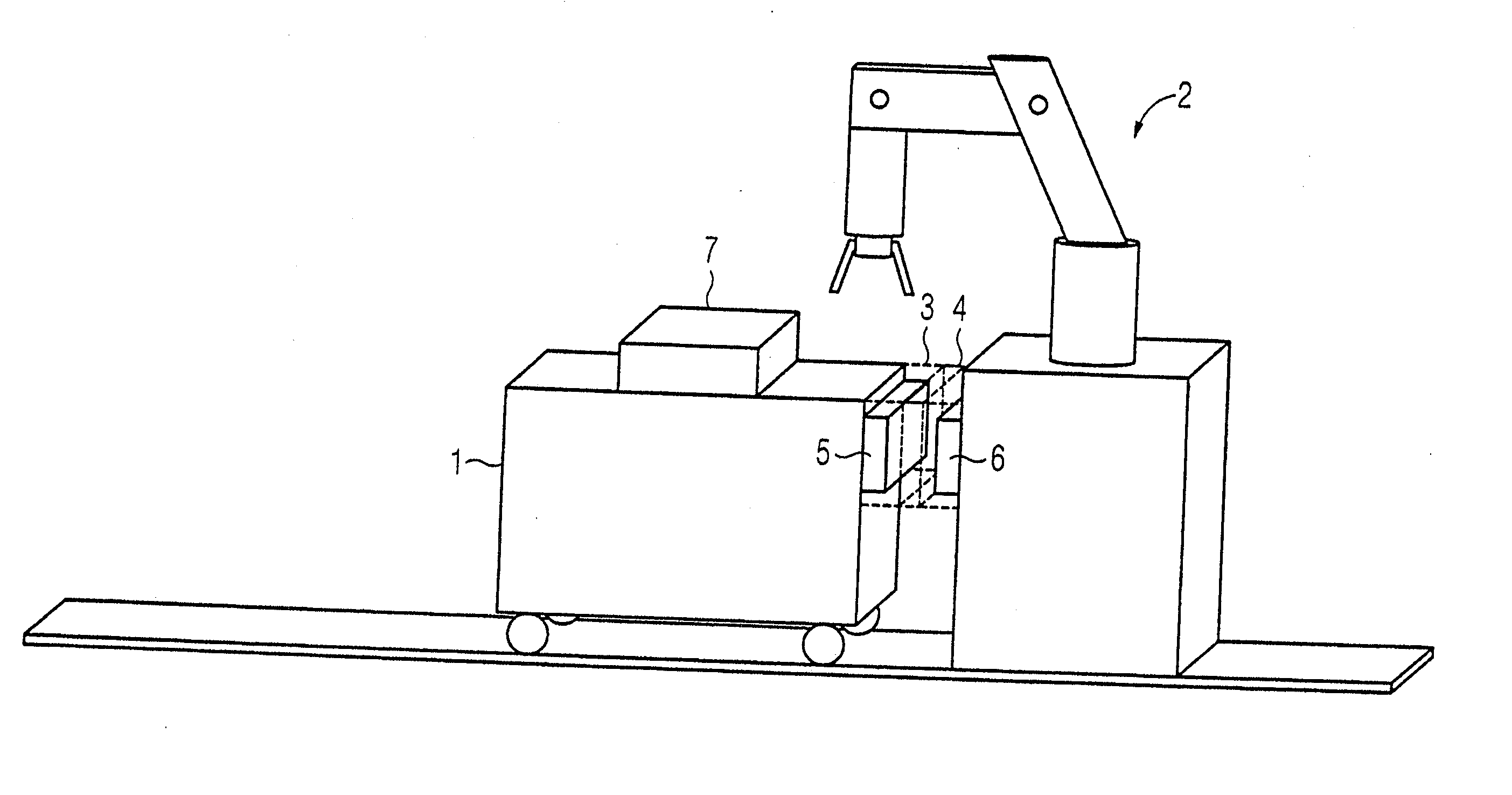

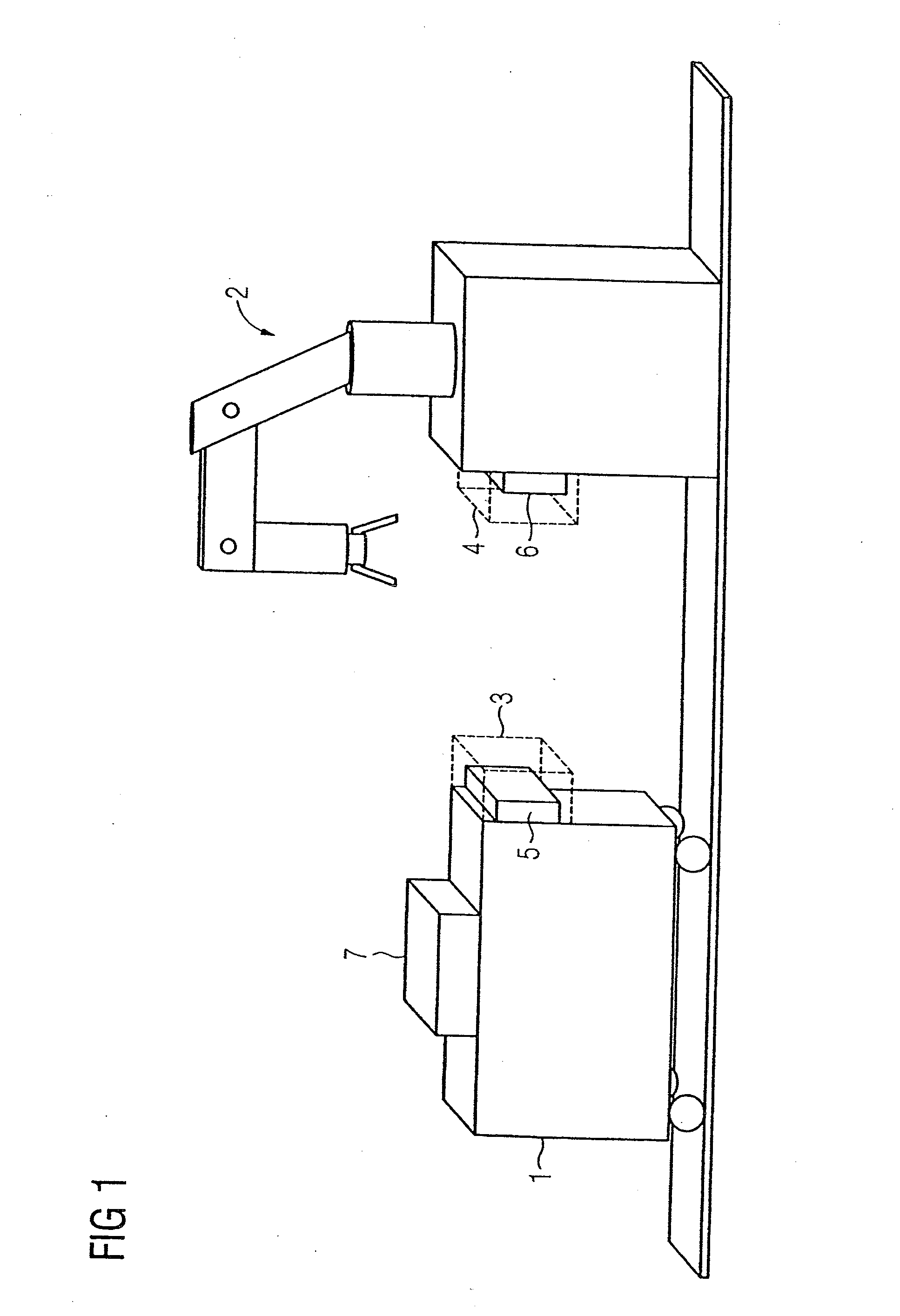

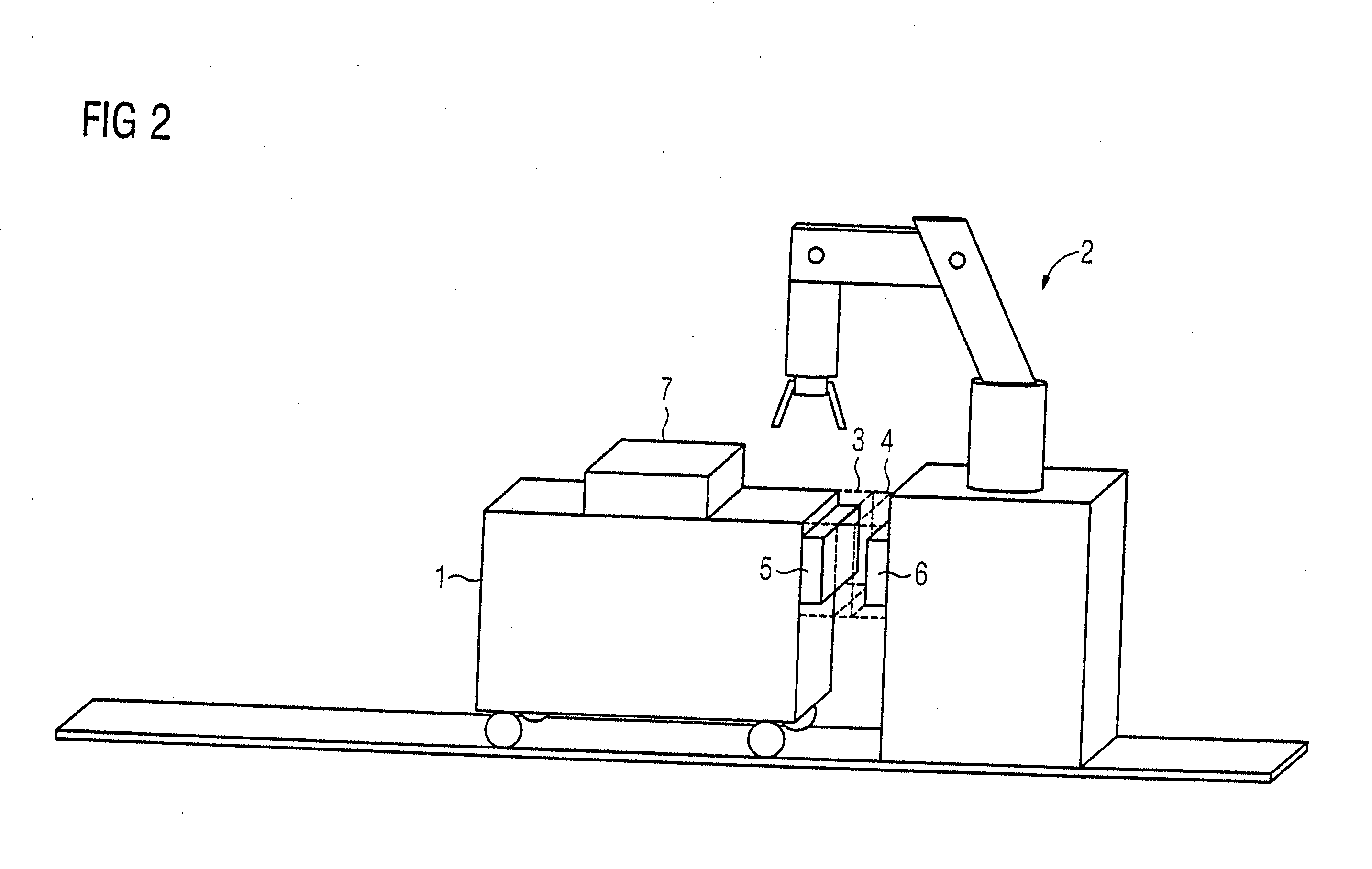

[0036]FIG. 1 shows a CAD drawing as a basis for generating a behavior model comprising a system in accordance with an embodiment of the invention, components 1,2 with open data interfaces 5,6 being represented. The drawing was developed with the aid of a CAD environment which is part of an extensive engineering system for the planning and designing automation systems. In the automation systems to be planned, workpieces 7 are moved on autonomous transport units, the figure showing by way of example the CAD representation of one of these transport units. Thus, a first component 1 of the automation system represents such a traveling transport unit which comprises a receptacle for a workpiece 7. A second component 2 of the automation system forms a processing station which is intended for processing the transported workpiece 7. The first component 1 transports the workpiece 7 during a production process to be simulated to the second component 2. The first component 1 contains a first in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com