Polycarbonate polyol, and synthetic method and application thereof

A synthesis method, polycarbonate technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as economic disadvantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] In this embodiment, the preset value of the mass percentage of carbonate contained in the rectified fraction is 32%.

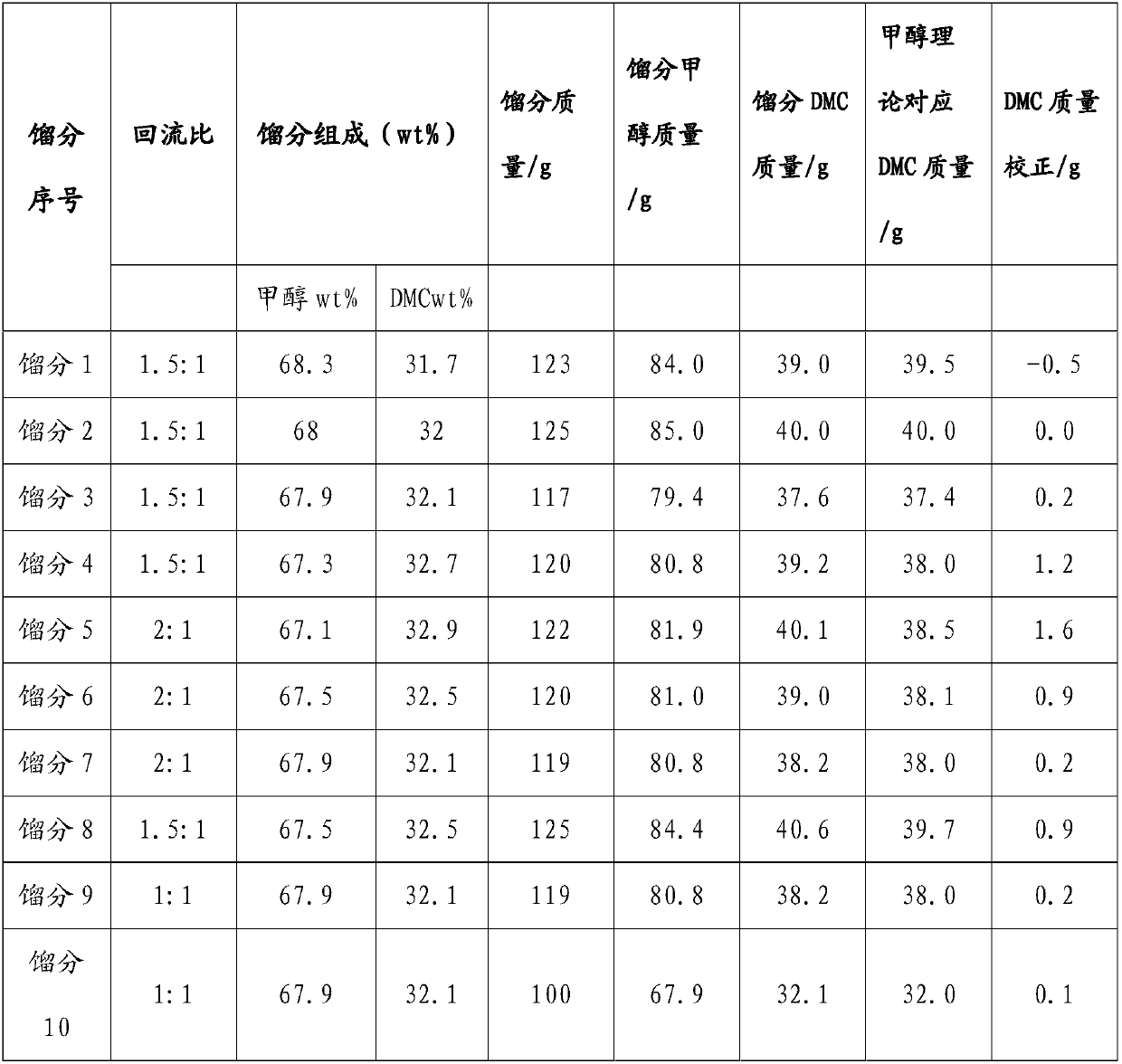

[0070] Weigh 1574 g of 1,5-pentanediol and 0.1574 g of isopropyl titanate and add them to a glass reactor equipped with an oil bath jacket, agitator, gas inlet, and rectification column. Vacuum and pass nitrogen three times to maintain normal pressure. Under the protection of nitrogen, the temperature was raised to a reaction temperature of 165° C., and 1700 g (the total amount of carbonate feed in stoichiometric amount) of dimethyl carbonate was slowly added dropwise to the system. Since the temperature at the top of the tower was observed to rise, fractions were continuously extracted with a reflux ratio of 2:1-1:1. During the continuous feeding process of dimethyl carbonate, adjust the reflux ratio according to the following table 1 to maintain the absolute value of the difference between the mass percentage of carbonate contained in the rectified frac...

Embodiment 2

[0078] In this embodiment, the preset value of the mass percentage of carbonate contained in the rectified fraction is 32%.

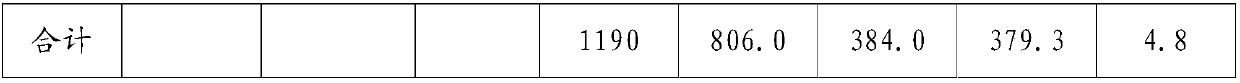

[0079] Weigh 16261g of 1,5-pentanediol, 18450g of 1,6-hexanediol and 3.45g of tetrabutyl titanate and add them to a stainless steel reactor equipped with an oil bath jacket, agitator, gas inlet, and rectification column in. Vacuum and pass nitrogen three times to maintain normal pressure. Under the protection of nitrogen, the temperature was increased to 156° C., and 35.0 kg (the total amount of carbonate feed in stoichiometry) of dimethyl carbonate was slowly added dropwise to the system. Since the temperature at the top of the tower was observed to rise, distillates were continuously extracted with a reflux ratio of 2:1. During the continuous feeding process of dimethyl carbonate, take online sampling and record the mass of the total fraction at the time of sampling, and subtract the mass of the total fraction recorded during the previous sampling in t...

Embodiment 3

[0087] In this embodiment, the preset value of the mass percentage of carbonate contained in the rectified fraction is 32.0%.

[0088] Weigh 494.2 g of neopentyl glycol, 560.7 of 1,6-hexanediol, and 0.0988 g of isopropyl titanate, and add them to a glass reactor equipped with an oil bath jacket, agitator, gas inlet, and rectification column. Vacuum and pass nitrogen three times to maintain normal pressure. Under the protection of nitrogen, the temperature was increased to 115° C., and 1000 g of dimethyl carbonate (the total amount of carbonate feed in stoichiometric amount) was slowly added dropwise to the system. Since the temperature rise at the top of the tower was observed, fractions were continuously extracted with a reflux ratio of 1.7:1, and the methanol:DMC ratio in the fraction fluctuated in the range of 66.1:33.9-66.5:33.5wt%. As the content of dimethyl carbonate in the fraction was monitored during the reaction to be higher than the preset value (see Table 3), 16.8 g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com