Foamed nickel loaded carbon embedded zero-valent iron cathode, preparation method and antibiotic degradation method

A zero-valent iron and foamed nickel technology is applied in the fields of nickel foam-supported carbon embedding zero-valent iron cathode and preparation and degradation of antibiotics. Performance optimization, beneficial to recycling, simple recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

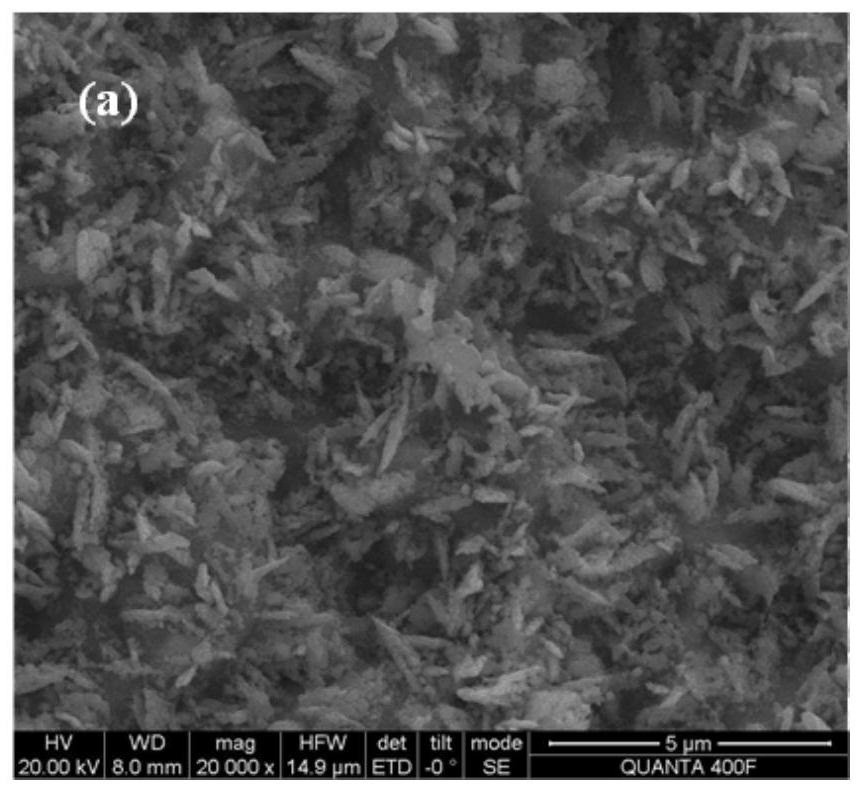

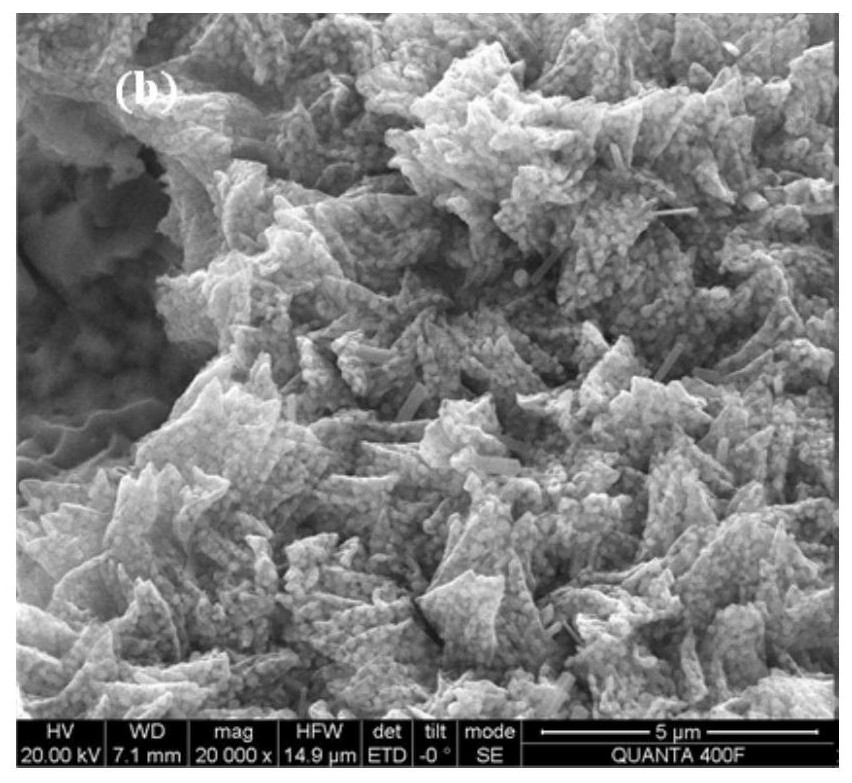

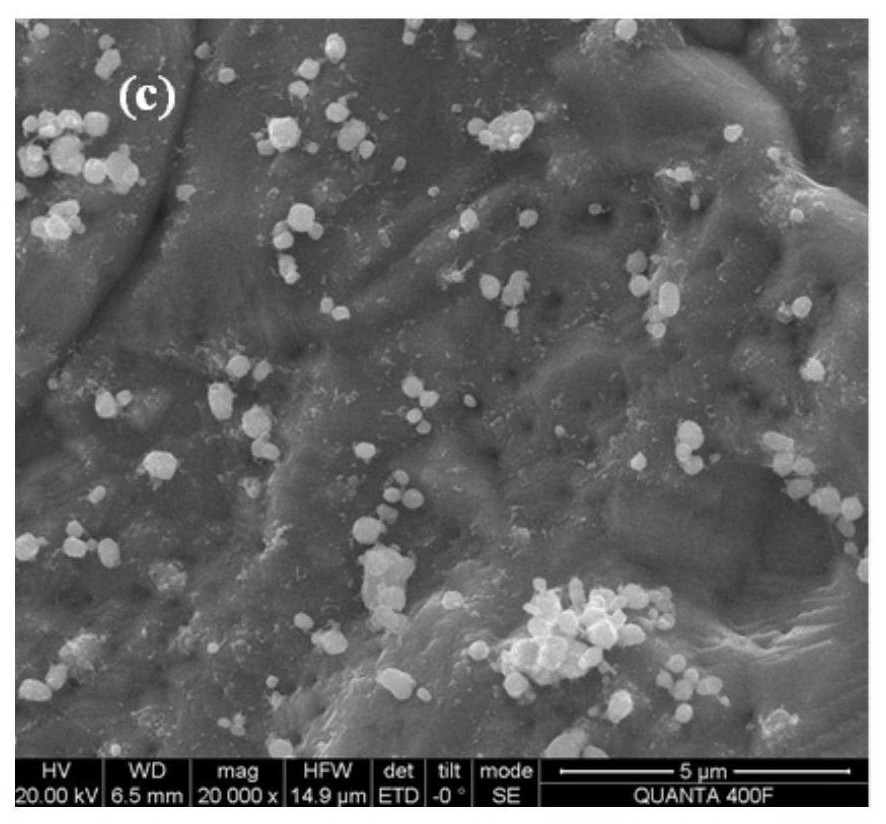

[0057] An embodiment of the present invention provides a method for preparing a zero-valent iron cathode embedded in NF-loaded carbon, which specifically includes the following steps:

[0058] (1) Pretreatment of nickel foam NF: cut NF according to the preset size, put the cut NF in a beaker, add a certain concentration of dilute hydrochloric acid to completely soak the NF, and ultrasonically clean it for 25-35 minutes. After cleaning, use the same method to replace with certain concentrations of acetone solution, absolute ethanol solution, and ultrapure water in sequence, and ultrasonically clean them for 15-25 minutes, 10-20 minutes, and 10-20 minutes respectively. In order to ensure that the residual acetone, ethanol and other substances on the NF were thoroughly cleaned, the ultrapure water was replaced and the cleaning was repeated for 10-20 minutes. The washed NF is aired in a ventilated place at room temperature for 24 hours until it is dried and set aside.

[0059] (2...

preparation Embodiment 1

[0065] This embodiment provides a method for preparing a NF-loaded carbon-embedded zero-valent iron cathode, which specifically includes the following steps:

[0066] (1) Cut the NF to 4*2.5cm, place the cut NF in a beaker and add 5mol / L dilute hydrochloric acid to completely soak the NF, clean it ultrasonically for 30min, and pour out the waste hydrochloric acid after cleaning. In the same way, they were ultrasonically cleaned with acetone for 20 minutes, absolute ethanol for 15 minutes, and ultrapure water for 15 minutes. In order to ensure that the residual acetone, ethanol and other substances on the NF were thoroughly cleaned, the ultrapure water was replaced and the cleaning was repeated for 15 minutes. The washed NF is aired in a ventilated place at room temperature for 24 hours until it is dried and set aside.

[0067] (2) Dissolve 0.01 mol of ferric chloride hexahydrate in 10 mL of DMF to obtain mother liquid A, and set aside; dissolve 0.01 mol of terephthalic acid (...

preparation Embodiment 2

[0071] The difference from Example 1 is that in step (4), under a nitrogen atmosphere, the temperature was raised from 5°C per minute to 700°C for two hours and then naturally cooled to room temperature. The obtained material was designated as C@Fe / NF(II).

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com