Method for synthesizing 1,1,1,3,5,5,5-heptamethyltrisiloxane by continuous catalysis of solid phase catalyst

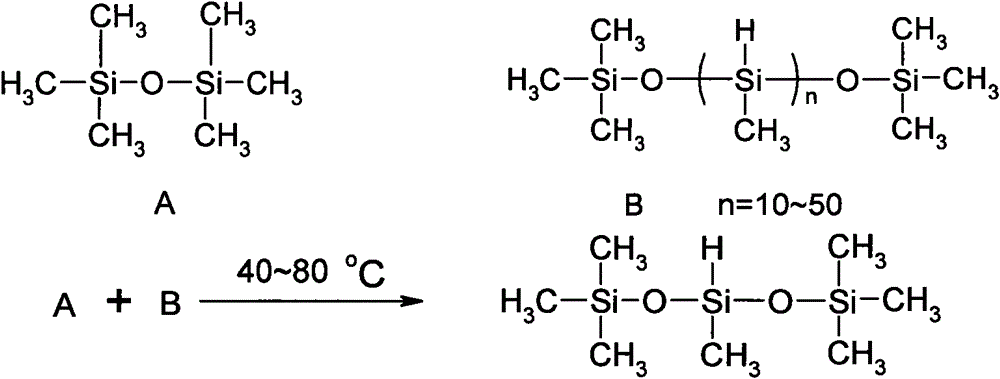

A technology for heptamethyltrisiloxane and hexamethyldisiloxane, which is used in the continuous catalytic synthesis of 1,1,1,3,5,5,5-heptamethyltrisiloxane using a solid-phase catalyst It can solve the problems of long reaction time, low yield and difficult separation, and achieve the effects of long reaction time, efficient and stable reaction, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

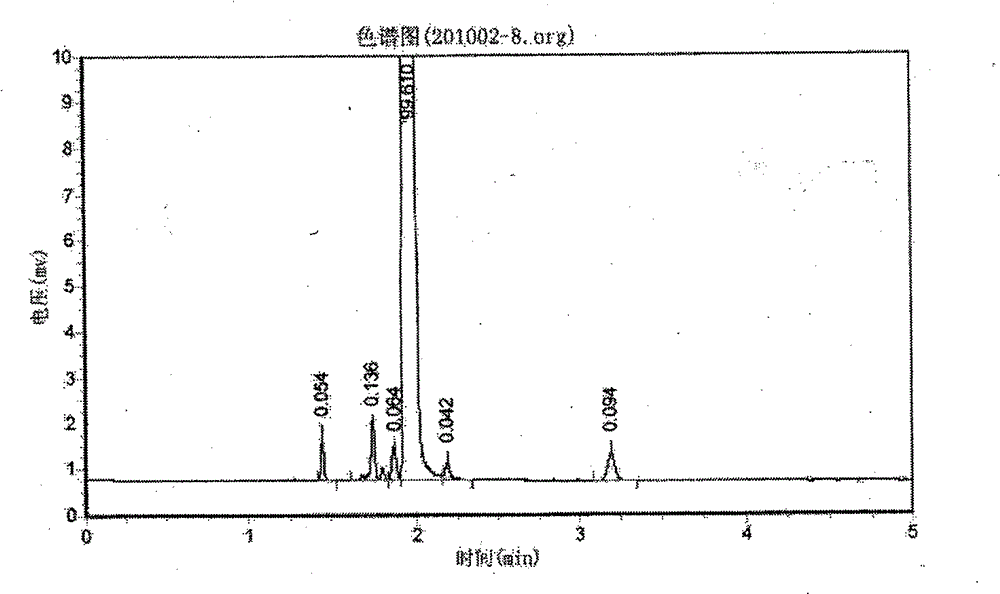

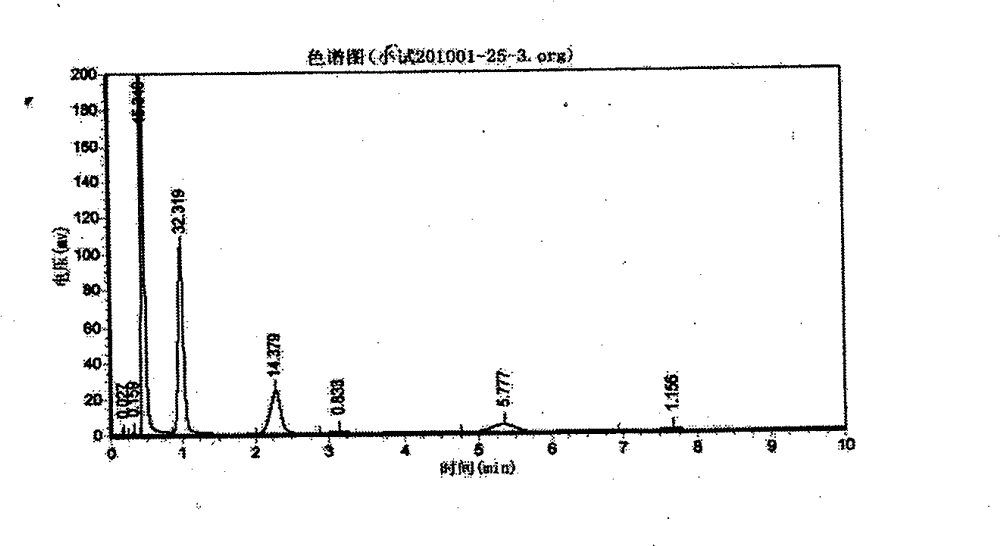

[0025] Example 1. A method for continuously catalyzing and synthesizing 1,1,1,3,5,5,5-heptamethyltrisiloxane by using a solid phase catalyst, in which: hexamethyldisiloxane and linear The raw materials of methyl hydrogen polysiloxane are continuously added to the fixed bed reactor with constant temperature jacket and strong acid type ion exchange resin at a molar ratio of 2.5:1 and a flow rate of 50mL / h. The reaction temperature is constant 60℃, catalyzed and balanced by the solid phase catalyst of the macroporous strong acid styrene-based cation exchange resin, the residence time is 6h, the reaction is continuous in the reactor, and the flow rate of the reaction product is controlled to flow directly from the fixed reactor, and the product from the reactor is used Gas chromatograph for quantitative analysis, the gas chromatogram is as figure 1 As shown, the content of MDHM is 32.3%. After high-reduction and low-reduction rectification, the fractions in the range of 141-2℃ are...

Embodiment 2

[0028] Example 2. A method for continuously catalyzing the synthesis of 1,1,1,3,5,5,5-heptamethyltrisiloxane using a solid-phase catalyst, wherein: hexamethyldisiloxane and linear methyl The molar ratio of the base hydrogen polysiloxane (MDHnM) raw materials is 3:1, the rest is the same as in Example 1, and the content of MDHM is 29.2%.

Embodiment 3

[0029] Example 3. A method for continuously catalyzing the synthesis of 1,1,1,3,5,5,5-heptamethyltrisiloxane using a solid phase catalyst, wherein: hexamethyldisiloxane and linear methyl The molar ratio of the base hydrogen polysiloxane (MDHnM) raw materials is 2:1, the rest is the same as in Example 1, and the content of MDHM is 30.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com