Thermal storage system, thermal storage container, thermal storage device using thermal storage container, and warm air device using thermal storage device

A heat storage system and heat storage technology, applied in heat storage equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problems of reduced heat utilization, complicated piping structure, and difficulty in heat storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

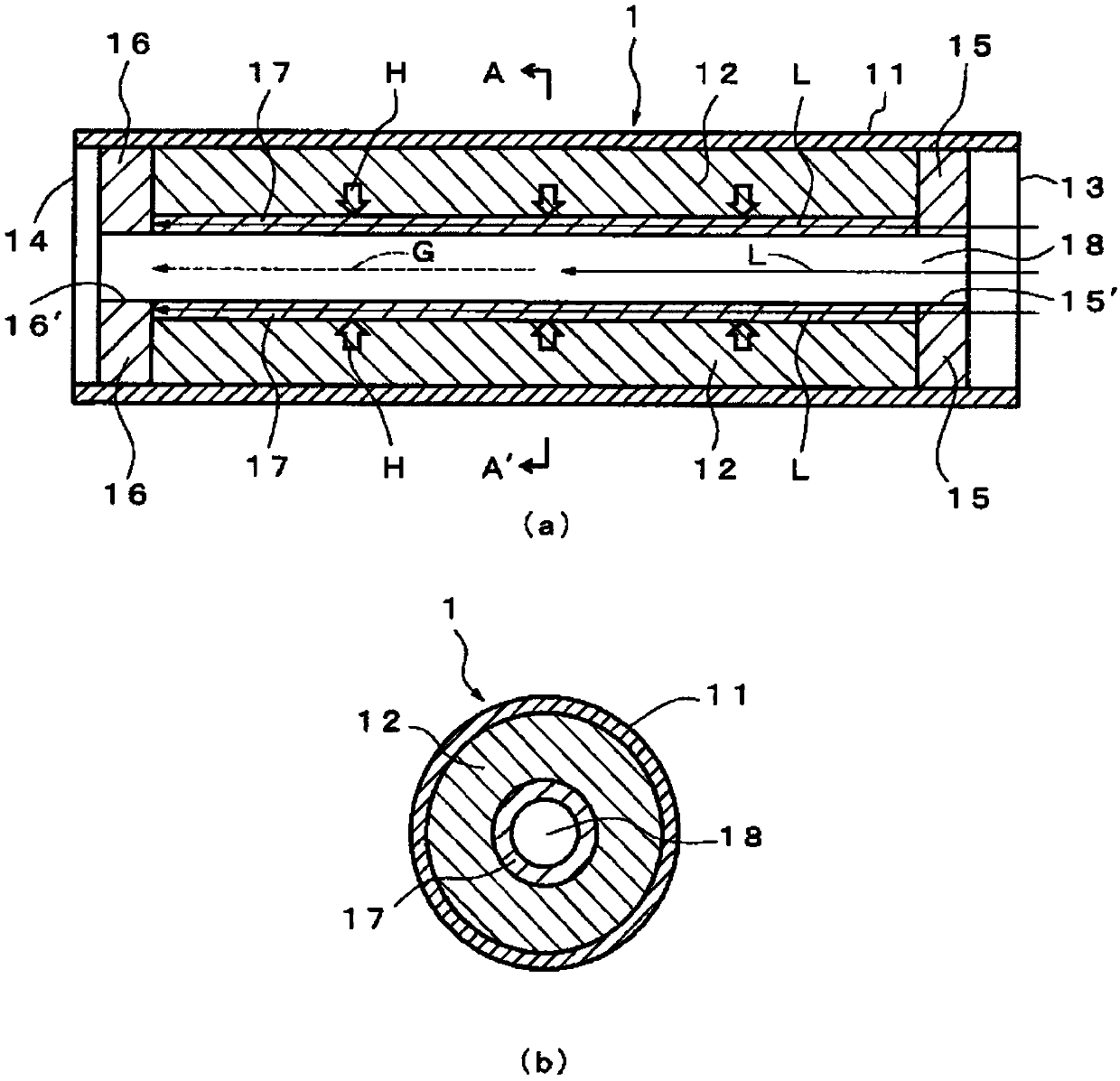

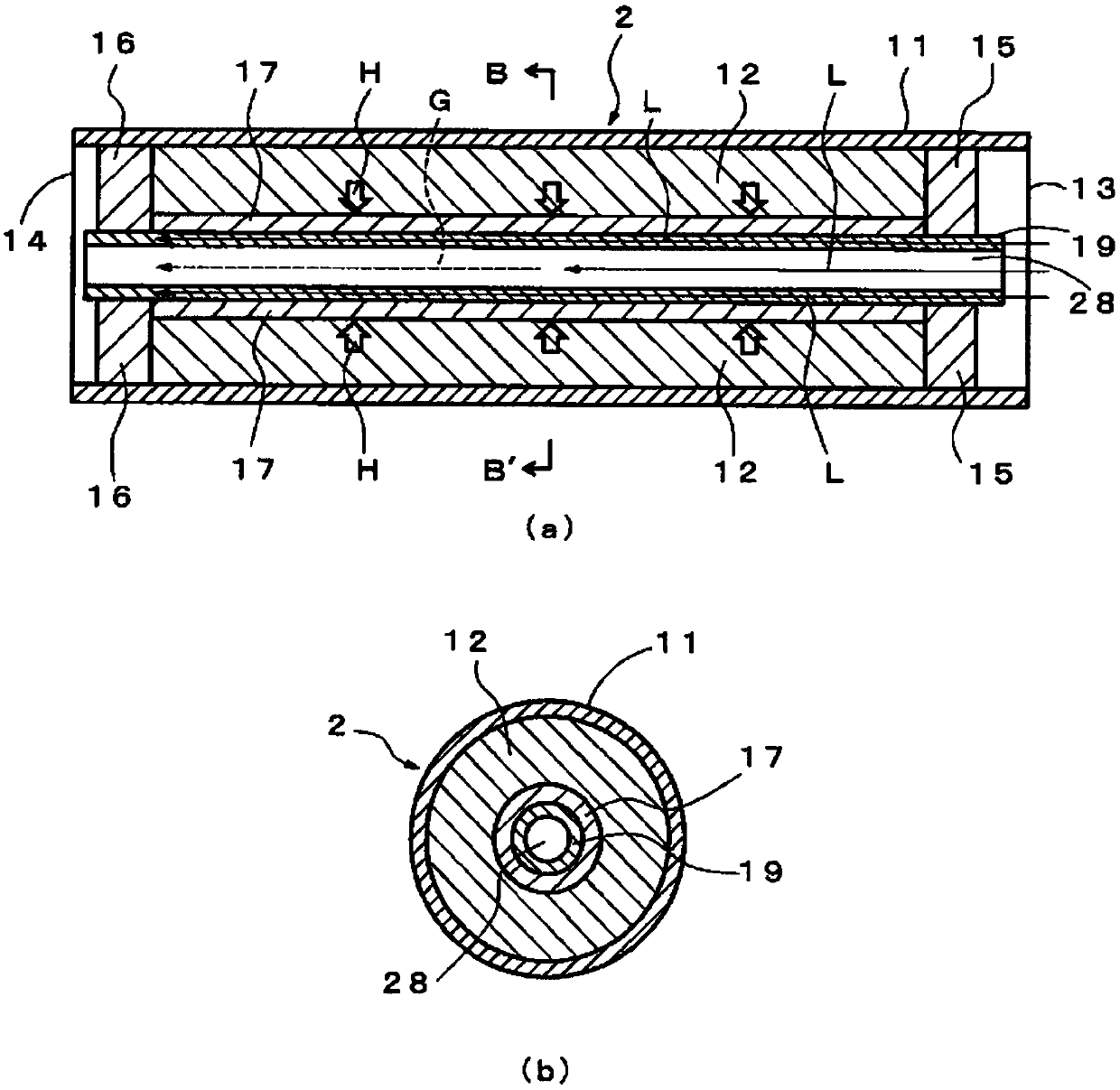

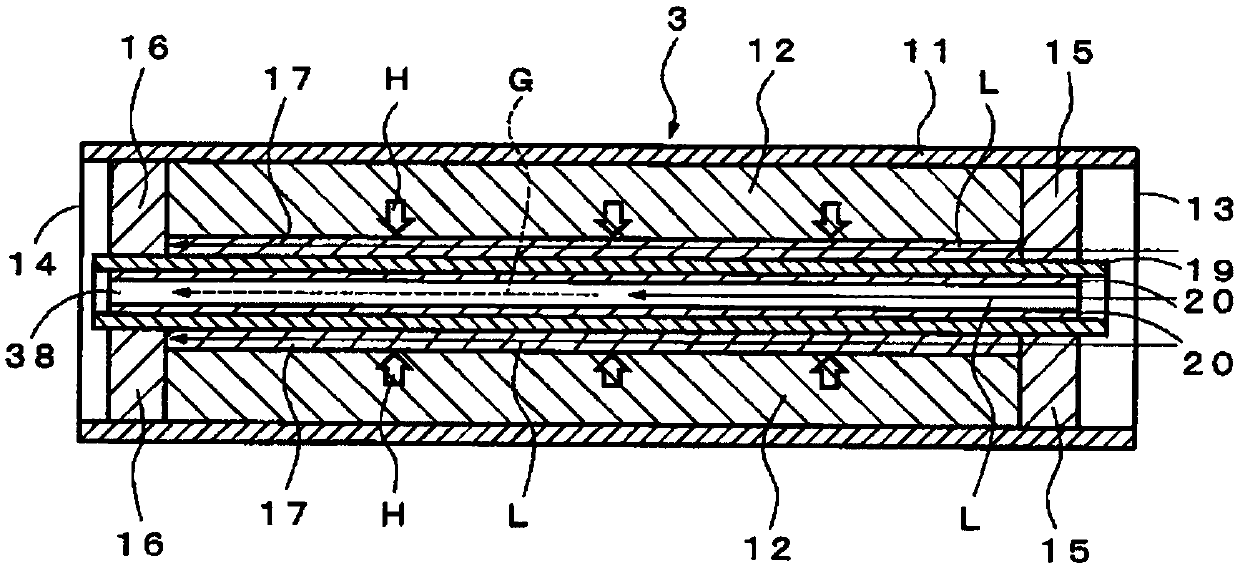

[0068] Hereinafter, the thermal storage container which concerns on 1st Embodiment of this invention is demonstrated using drawing. Such as figure 1 As shown in (a), the heat storage container 1 according to the first embodiment includes a cylindrical body 11 which is a tubular body with both ends opened, and an adsorbent 12 arranged inside the cylindrical body 11 . In addition, the heat storage container 1 includes: a first cover 15, which is arranged adjacent to the one end 13 side of the cylindrical body 11 of the adsorbent 12, and is made of a porous body; The other end portion 14 side of the cylindrical body 11 is adjacently disposed and is made of a porous body; The inner side of 12 is arranged adjacent to a diffusion layer for transporting liquid, and has a capillary structure.

[0069] Such as figure 1 As shown in (b), the cross section in the radial direction of the cylindrical body 11 is circular. In addition, the adsorbent 12 is a form in which powder is compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com