A kind of gasification furnace and its application, gasification method of carbonaceous material

A technology of gasification furnace and gasification reaction, which is applied in gasification process, gasification device details, granular/powder fuel gasification, etc. problems such as large losses, to achieve the effect of improving the online rate of the gasifier, improving the efficiency of cold gas, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

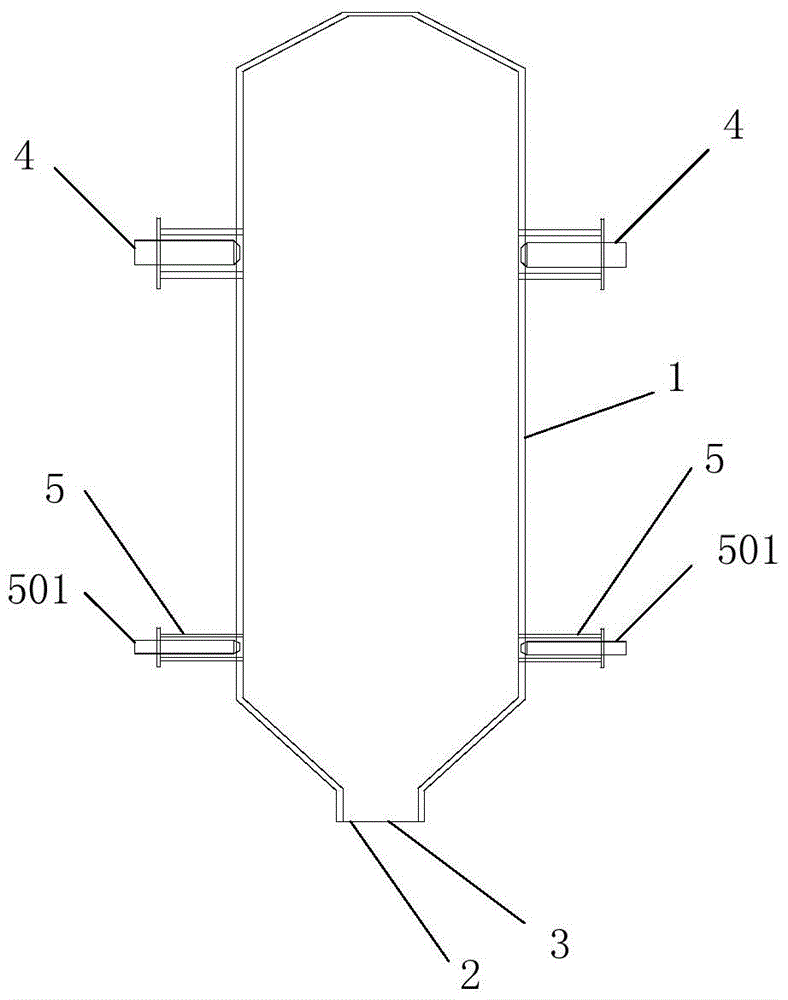

[0038] In this embodiment, the structure of the gasifier used is as figure 1 As shown, the gasification furnace includes a vertical furnace body 1, and the vertical furnace body 1 is provided with a slag outlet 2, a synthesis gas outlet 3 and two process burners 4, the vertical furnace body Two flux nozzle chambers 5 and a flux nozzle 501 installed in the flux nozzle chamber 5 are also fixed on the side wall of the middle and lower section of 1, and the two flux nozzle chambers 5 are arranged in the vertical The furnace body 1 has the same cross section and is evenly distributed along the cross section. The slag outlet 2 and the synthesis gas outlet 3 are the same outlet, and both are arranged at the bottom of the vertical furnace body 1. The process burner 4 is arranged on the side wall of the upper section of the vertical furnace body 1.

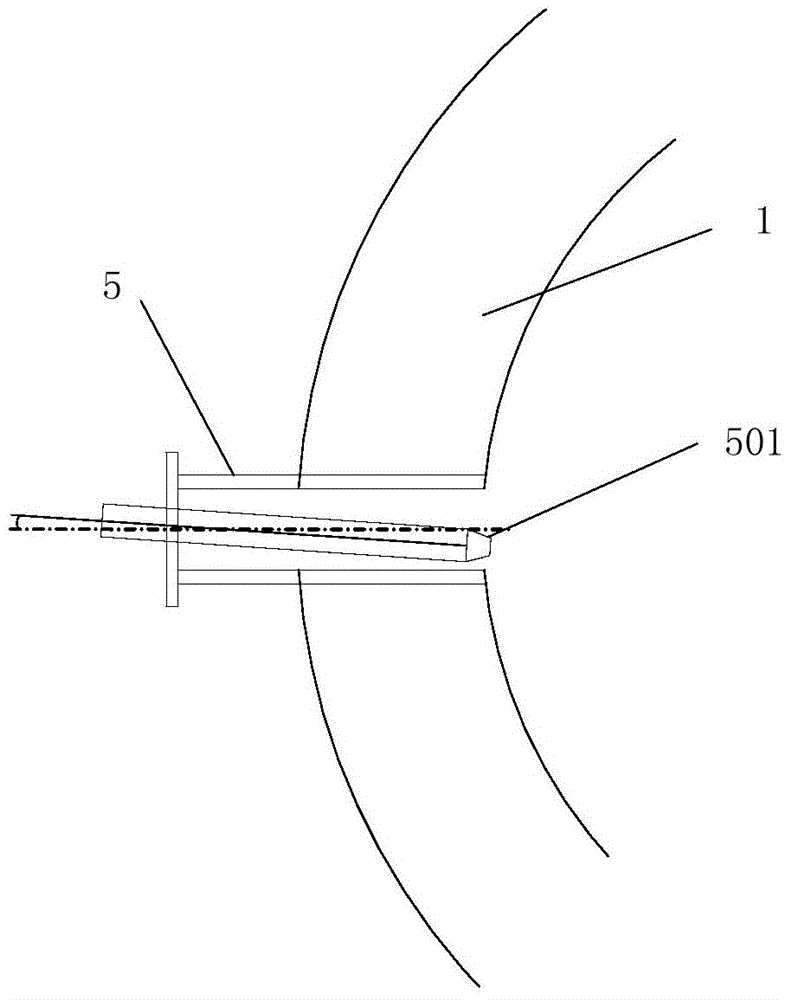

[0039] The enlarged schematic diagram of the structure of the flux nozzle chamber 5 and the flux nozzle 501 is as follows: figure 2 Shown....

Embodiment 2

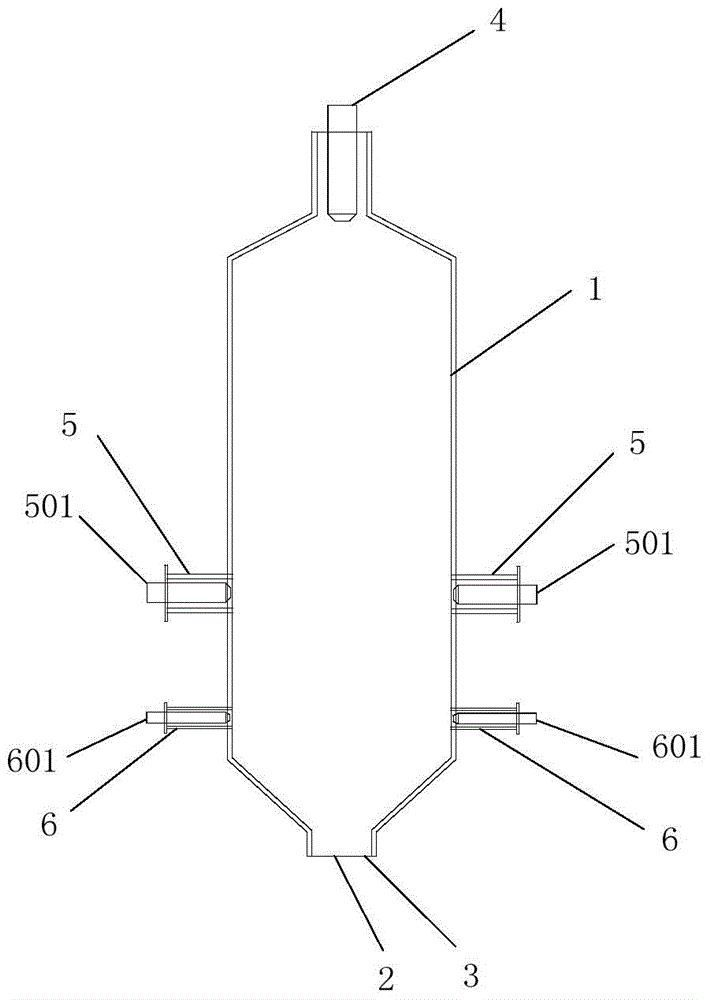

[0053] The condition of this embodiment is compared with that of embodiment 1, the only difference is: this embodiment uses image 3 In the structure of the gasification furnace, 6 is a staged oxygen supply nozzle chamber, and 601 is a staged oxygen supply nozzle set in the staged oxygen supply nozzle chamber 6. The angle between the axis of the flux nozzle 501 on the horizontal plane and the axis of the flux nozzle chamber 5 is 30°; the height of the axis of the flux nozzle chamber 5 from the bottom of the vertical furnace body 1 is 0.3 times the height of the vertical furnace body 1; on the side wall of the middle and lower section of the vertical furnace body 1, two graded oxygen feeding nozzle chambers 6 are also fixed, which are arranged in the flux nozzle chamber 5 On the vertical furnace body 1 below and on the vertical furnace body 1 above the slag tap 2; two graded oxygen nozzle chambers 6 are fixedly arranged on the same cross section of the vertical furnace body 1 Th...

Embodiment 3

[0059] The condition of this embodiment is compared with that of embodiment 1, the only difference is: this embodiment uses Figure 4 The structure of the gasification furnace, the number of process burners 4 is 3, in addition to the two process burners arranged on the side wall of the upper section of the vertical furnace body 1, it also includes the top of the vertical furnace body 1 A craft burner. In addition to the coal in Example 1, the raw materials are also blended with 10% residual oil.

[0060] After gasification using the gasifier of this embodiment, the amount of flux (limestone) added can be reduced to 6wt% (coal-based), the wall heat loss of the gasifier is reduced to 3%, and the effective gas component is increased to 89.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com