Organic solid waste semi-in-situ carbon sequestration gasification device and application thereof

A technology for organic solids and wastes, applied in gasification process, educts, production of combustible gases, etc., can solve the problems of environmental pollution, slow natural degradation of organic solid wastes, etc., achieve the goal of carbon neutrality, and speed up the scale. Processing and utilization process, the effect of reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 device embodiment

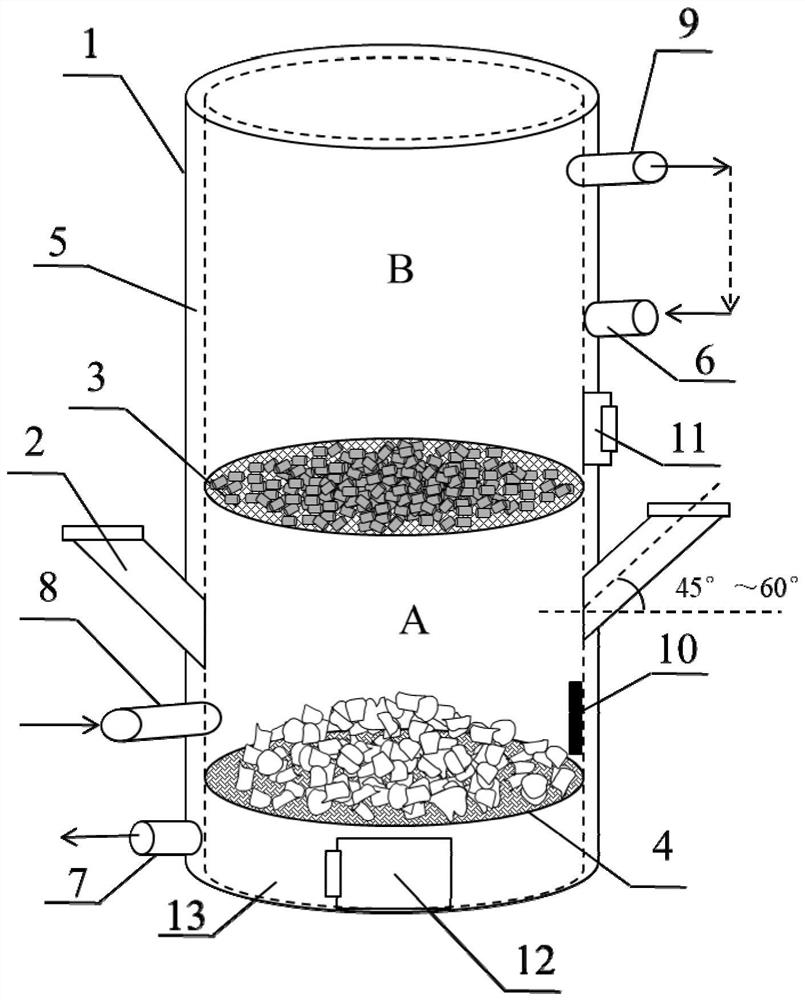

[0021] Such as figure 1 As shown, a semi-in-situ carbon fixation gasification device for organic solid waste, the device includes a cylindrical, vertical gasification furnace body 1, a semi-in-situ catalyst grid 3, a movable grate 4, a heat supply Interlayer 5, temperature controller 10; the movable fire grate 4 is under the semi-in-situ catalyst net 3, and the heating interlayer 5 wraps the movable fire grate 4 and the semi-in-situ catalyst net 3; the heat supply interlayer 4 is a gas The furnace body 1 provides heat, the catalyst is placed on the semi-in-situ catalyst net 3, and the organic solid waste is placed on the movable grate 4. The gasification furnace body 1 includes an organic solid waste feeder 2 , a carbon dioxide inlet 8 , a combustible gas outlet 9 , a catalyst replacement port 11 , a temperature controller 10 , an ash outlet 12 , and an ash bin 13 . The central axis of the organic solid waste feeder 2 is 45°-60° to the...

Embodiment 2

[0022] Embodiment two working embodiment

[0023] When the device in Embodiment 1 is working, the catalyst (generally nickel-based catalyst, etc.) is placed on the semi-in-situ catalyst grid 3 through the catalyst replacement port 11; In the heat supply interlayer 5, carbon dioxide with a set flow rate enters the gasification furnace body 1 through the carbon dioxide inlet 8. After the temperature controller 10 is constant at the set temperature, the hot air supply of the hot air inlet 6 and the output of the hot air outlet 7 are constant. The air volume keeps the temperature in the gasification furnace body 1 stable; the organic solid waste enters the gasification furnace body 1 through the feeder 2 and falls to the movable grate 4, and the gas after the organic solid waste is cracked in the gasification cracking space A The reaction is carried out in a carbon dioxide atmosphere, and the volatile matter produced by the reaction is placed in the net through the semi-in-situ ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com