Method and device for molding sterile container, and method and device for sterile filling

A technology of aseptic container and molding method, which is applied to household components, household appliances, other household appliances, etc., can solve the problems of increasing consumption of hydrogen peroxide, increasing mist flow, etc., and achieve the effect of improving sterilization effect and preventing corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

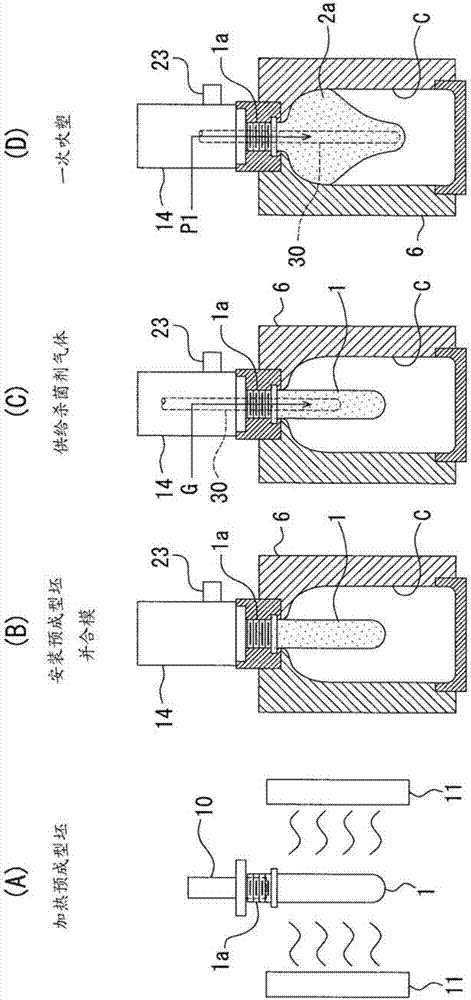

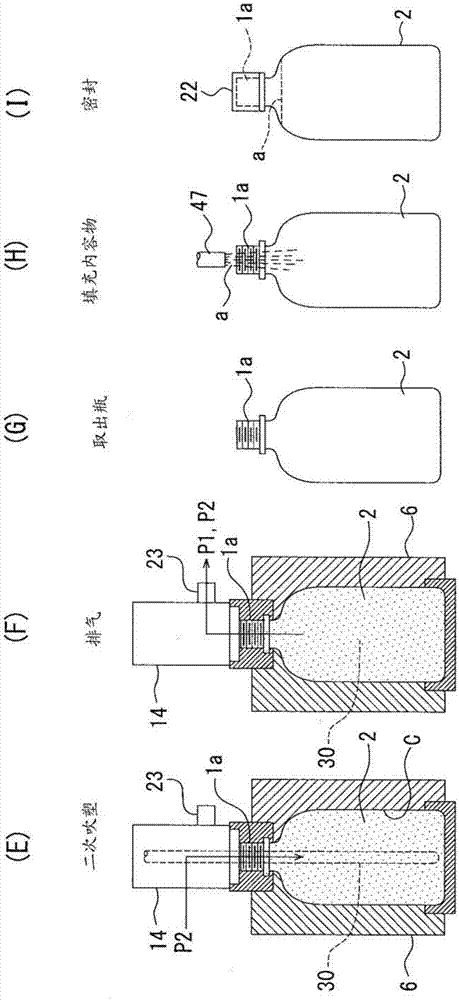

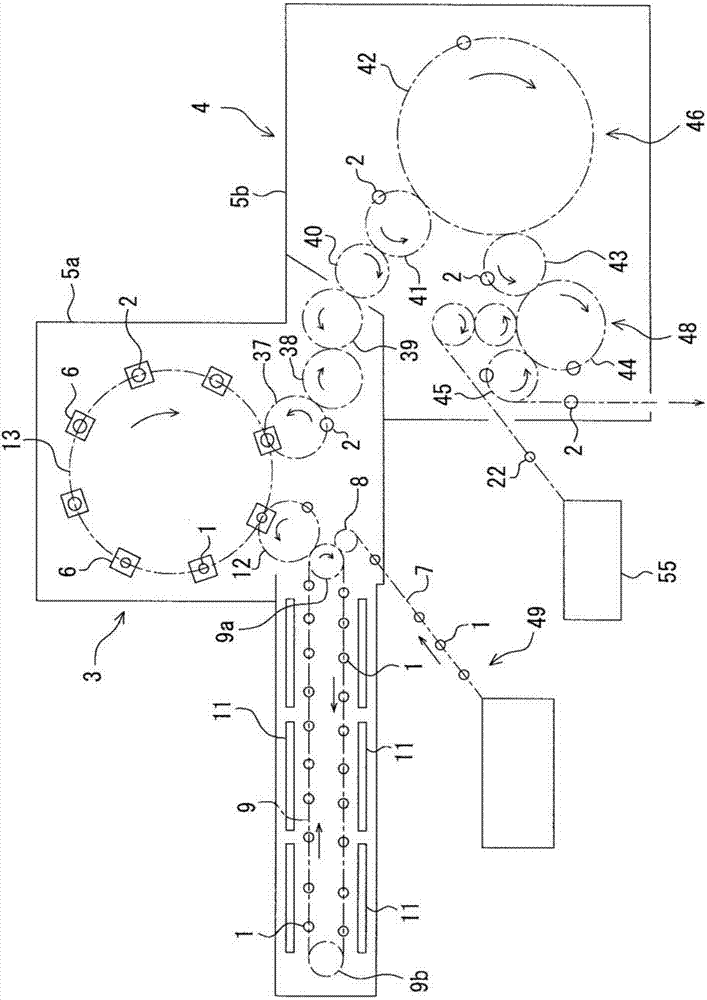

[0045] Such as image 3 As shown, the aseptic filling device is equipped with the ability to sequentially supply preforms 1 at predetermined intervals (refer to figure 1 (A)) the preform supply machine 49, the preform 1 is molded into a bottle 2 as a container (refer to figure 2 (G)) the blow molding machine 3, for the bottle 2 after molding, content a such as beverage (referring to figure 2 (H)(I)) The filling machine 4 that fills the bottle 2 and seals it.

[0046] The position from the preform supply machine 49 to the filling machine 4 is covered with chambers 5a, 5b as protective covers. The interior of chambers 5a and 5b is maintained at a positive pressure by always supplying sterile air from a sterile air supply source not shown in the figure.

[0047] Preform 1 as figure 1 As shown in (A), it is a test tube-shaped bottomed cylindrical body, which is made of PET (polyethylene terephthalate), for example, by injection molding or the like. The preform 1 is finished...

Embodiment approach 2

[0132] Such as Figure 7 As shown, in this second embodiment, an air flushing nozzle 54 for air flushing the bottle 2 is provided on the conveyance path of the molded bottle 2 between the blow molding machine 3 and the filling machine 4 .

[0133] One or more nozzles 54 for air washing are arranged around the wheel 39, for example. Instead of the wheel 39 or in addition to or in addition to the wheel 39, it may be arranged around the wheel 37, the wheel 40, or the wheel 41.

[0134] In addition, a delivery duct (not shown) positively pressurized with sterile air may be provided around the wheel 39 and the like, and the bottle 2 may be passed through the delivery duct to blow sterile air into the bottle 2 . Air. Thereby, air flushing of the bottle 2 can also be performed.

[0135] When the bottle 2 molded by the molding die 6 of the blow molding machine 3 is traveling around the wheel 39, as Figure 8 As shown in (A), sterile air N is blown from the nozzle 54 for air washin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com