High-efficiency and energy-saving gasifier

A high-efficiency energy-saving, gasifier technology, applied in the chemical industry, the manufacture of combustible gas, climate sustainability, etc., can solve the problems of inconvenient feeding, waste gas, incomplete decomposition and utilization of tar, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawings and examples.

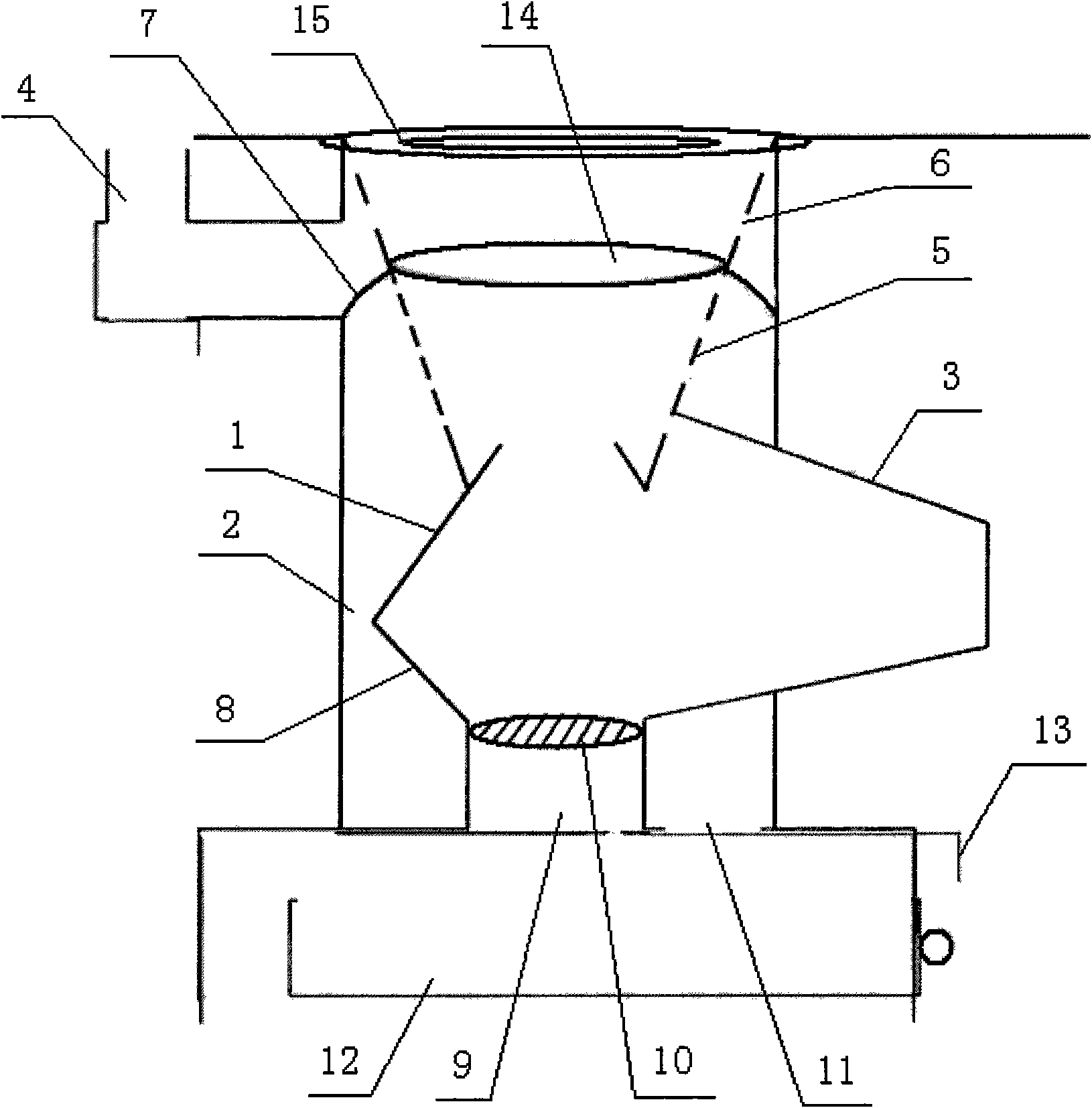

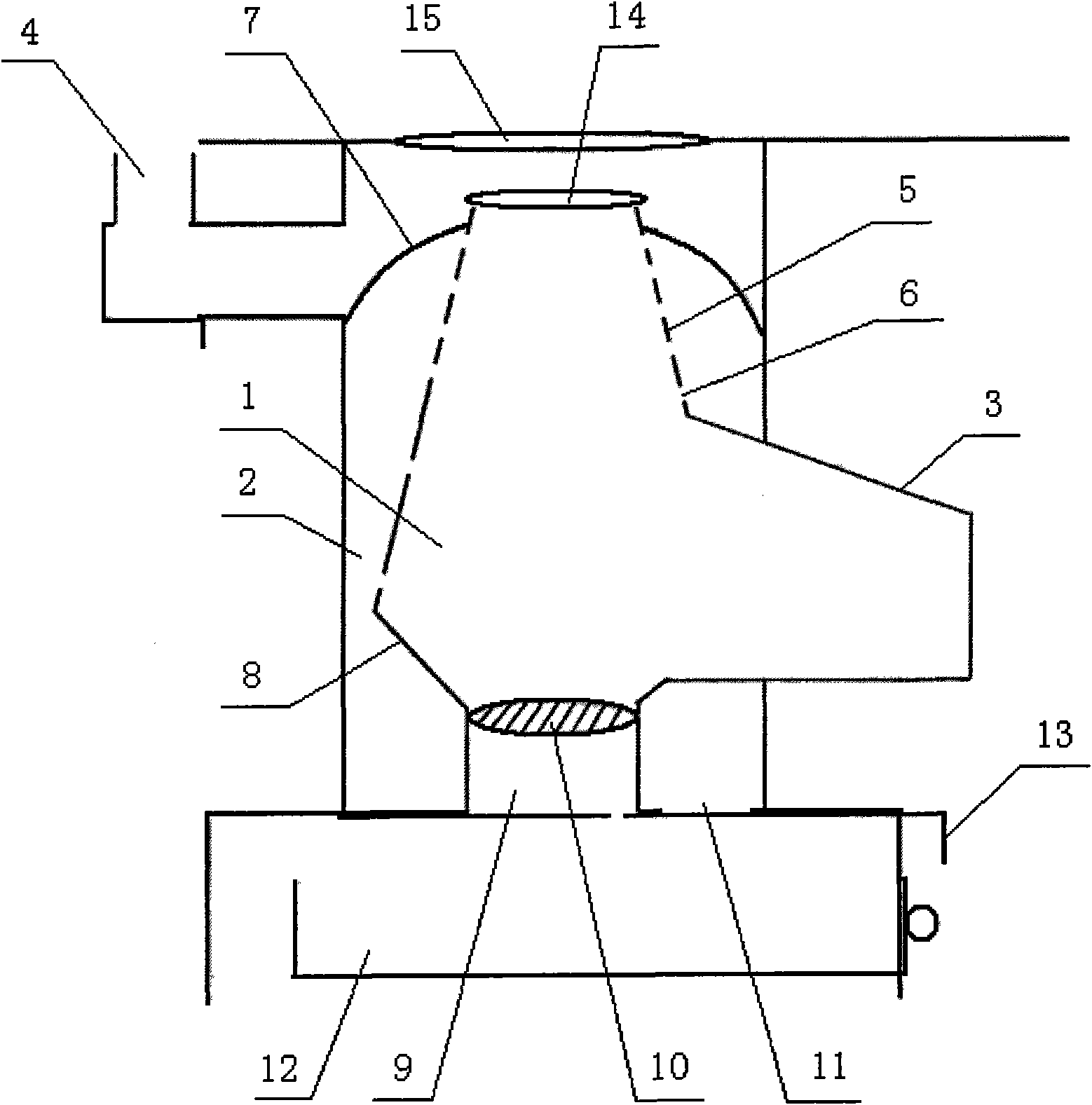

[0013] Such as figure 1 As shown, a high-efficiency energy-saving gasification furnace includes a furnace body 2, a multi-cone furnace core 1, a feed port 3 and an exhaust channel 4. The furnace core is formed by sealing and connecting three sections of cones, and the upper cone of the furnace core A plurality of air holes 6 are distributed on the 5, the partition plate 7 is airtightly connected with the middle and upper part of the upper cone of the furnace core, the lower cone of the furnace core 8 is connected with the air inlet 19, and the furnace tooth 10 is installed at the upper end of the air inlet I 9, and the furnace body There is an air inlet II11 at the lower end, and an air duct is opened inside the base 12. A sliding damper 13 is provided at the connection between the furnace body 2 and the base 12, and the damper controls the opening and closing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com