Magnetic force plug-in type electronic cigarette, manufacturing method, connecting assembly and atomization assembly

A technology for connecting components and atomizing components, applied in the field of electronic cigarettes, can solve problems such as short lifespan, inconvenient portability and replacement, and unreliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] The present invention will be described in further detail below in conjunction with accompanying drawing:

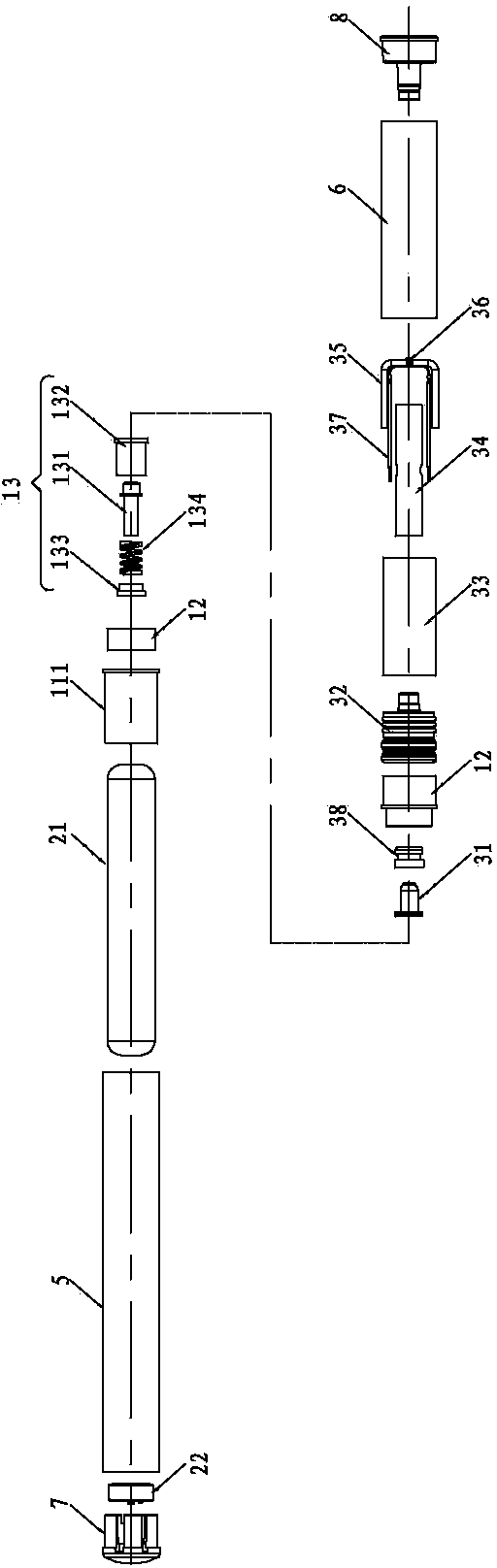

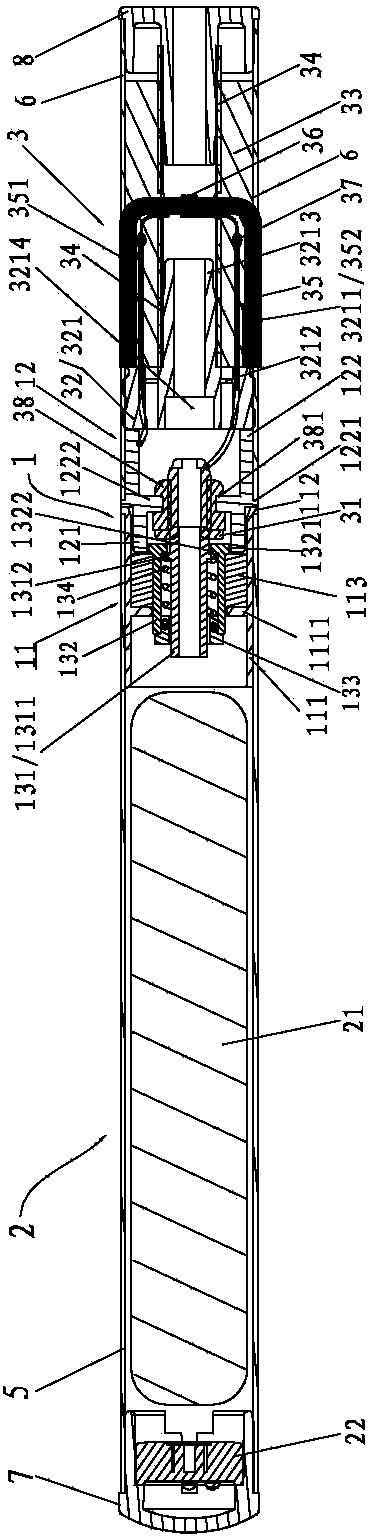

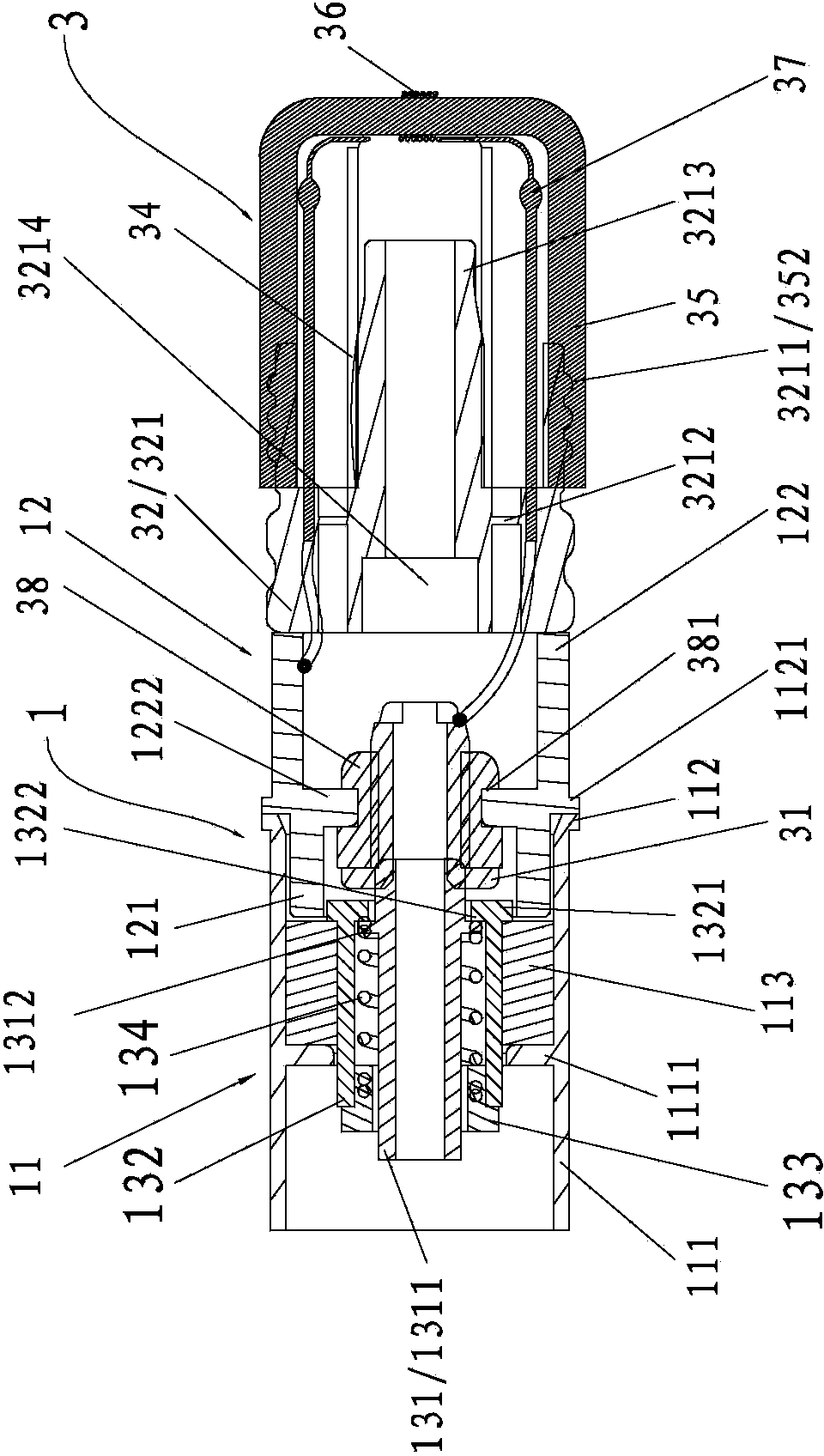

[0105] Figure 1 ~ Figure 3 A first embodiment of the invention is shown.

[0106] see figure 1 , figure 2As shown, the magnetic plug-in electronic cigarette includes a connection assembly 1, and the two ends of the connection assembly 1 are respectively connected to the power supply assembly 2 built in the smoke pipe 5 and the atomization assembly 3 built in the atomization pipe 6. The connection The component 1 includes a strong magnetic component 11 and a metal component 12 assembled together by magnetic attraction, and the strong magnetic component 11 is in contact with the metal component 12 through the protruding edge 112 and the protruding edge 1221 extending radially from each head, And the head extension 121 of the magnetic assembly 12 arranged axially along the head is fitted and abutted against the inner cavity of the strong magnetic assembly 11, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com