Patents

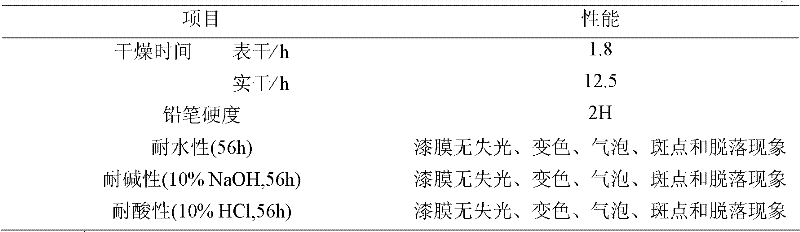

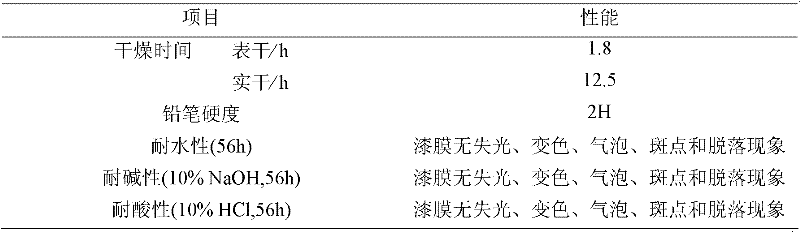

Literature

31results about How to "Has "self-emulsifying" properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane-polyacrylacid ester interpenetrating network polymer, preparation and use thereof

The invention relates to a polyurethane-polyacrylic ester interpenetrating network polymer and a preparation method and the application thereof. The following steps are comprised: self-emulsifying anionic polyurethane water dispersoid containing carbon-carbon double bonds are synthesized through a step addition polymerization method; the synthesized polyurethane water dispersoid is used as seeding emulsion and polymer surface active agent; in-situ emulsion polymerization is carried out on acrylic ester monomer in an emulsification system by using dropwise adding evocating agents, so that the pre-emulsifying acrylic monomers in the system can be polymerized and (or) cross-linked on the inner part and the surface of seeding emulsion particles, and then the polyurethane-polyacrylic ester interpenetrating network polymer emulsion can be obtained; after dried, emulsion powder which has good water resisting property and cohesiveness when re-dispersed in water is obtained; the polyurethane-polyacrylic ester interpenetrating network polymer not only can be used with inorganic cementing materials such as cement, white lime or plaster for manufacturing overcoating mortar, pointing-joint agents, plastering agents and building bonding agents, but also can be independently used as film forming binder for preparing dry powder emulsion coating.

Owner:SOUTH CHINA UNIV OF TECH

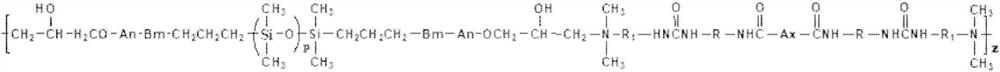

Preparation method for polysiloxanes-amidopolyether block copolymer

InactiveCN102199295ABroad encapsulationWide penetration abilityFibre treatmentPolyelectrolyteEmulsion

The invention discloses a preparation method for a polysiloxanes-amidopolyether block copolymer, comprising the steps of preparation of an intermediate of alpha, omega-hydrosiloxane, preparation of an intermediate of alpha, omega-polysiloxanes diepoxide, and preparation of the polysiloxanes-amidopolyether block copolymer. The polysiloxanes-amidopolyether block copolymer provided in the invention enables a textile finishing agent to be stable under condition of high temperature, a polyelectrolyte, a high pH value or a high shear force without breaking emulsion, sticking to a roller or a cylinder and producing oil marks, allows textiles finished to be returned for repairing, and is widely used in fields like chemical fiber, natural fiber and blended products thereof, etc.

Owner:HANGZHOU MEIGAO HUAYI CHEM

Preparation method of anionic organic-solvent-free and emulsifier-free polyurethane microemulsion

InactiveCN102977282AHas self-emulsifying propertiesHigh solid contentCoatingsGraft polymer adhesivesPolymer scienceAdhesive

The invention discloses a preparation method of an anionic organic-solvent-free and emulsifier-free polyurethane microemulsion. The preparation method comprises the following steps of: carrying out polymerization of isocyanate and polymer polyol by replacing an organic cosolvent used in the preparation process of the traditional polyurethane-polyacrylate microemulsion with inertial vinyl monomers to prepare a polyurethane prepolymer of which the terminal group is provided with unsaturated bonds, carrying out cooling, neutralization and aqueous dispersion on the polyurethane prepolymer, and then further initiating the polymerization of the vinyl monomers under the action of a water-soluble initiator to prepare the anionic organic-solvent-free and emulsifier-free polyurethane microemulsion. The preparation method disclosed by the invention thoroughly gets rid of the organic cosolvent added in the traditional waterborne polyurethane and achieves a real sense of environmental friendliness; and in addition, no emulsifier is added in the preparation process, and the prepared anionic organic-solvent-free and emulsifier-free polyurethane microemulsion has nano-scale particle diameter, is excellent in performance and can be used for a waterborne coating and the field of adhesives due to formula adjustment.

Owner:SHAANXI UNIV OF SCI & TECH

Self-emulsified aqueous epoxy emulsion and method for preparing same

The present invention provides one kind of self-emulsifying water thinned epoxy emulsion and its production process. The self-emulsifying water thinned epoxy emulsion is produced through emulsion copolymerization with the polymer intermediate, which is obtained through polymerizing the mixed organosilicon monomer comprising alkenyl-containing trimethyl silane and octalkyl cyclotetrasiloxane and acrylic acid monomer, epoxy resin and acrylic acid monomer. The self-emulsifying water thinned epoxy emulsion has homogeneous particle size, high stability, and stable production process. The anticorrosive paint compounded with the self-emulsifying water thinned epoxy emulsion reaches the level of solvent type epoxy resin paint.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Method for synthesizing cellulose nitrate-polyurethane-polyacrylic acid(polyacrylate) composite emulsion

InactiveCN101235125AHas self-emulsifying propertiesGood drying propertiesEmulsion paintsActive agentEmulsion

The invention discloses a preparation method of cellulose nitrate-polyurethane-polyacrylic acid (ester) composite emulsion, which comprises using toluene diisocyanate, dealcoholized cellulose nitrate, polyether polyol, butanediol, dimethylol propionic acid and triethylamine as main raw materials, using step addition polymerization to synthesize anion polyurethane-cellulose nitrate water disperser, using the water disperser as seed emulsion, without any surface activator, via adding inducer to process in-site emulsion polymerization with polymer emulsion and emulsified acroleic acid monomer, to process polymerization and / or crosslink of pre-emulsified acroleic acid(ester) monomer in the seed emulsion seed and at surface, thereby preparing aqueous cellulose nitrate-polyurethane-polyacrylic acid (ester) composite latex particle with core-shell structure or interpenetrating polymer which can be used as filming polymer of high-performance aqueous wood dye.

Owner:SOUTH CHINA UNIV OF TECH

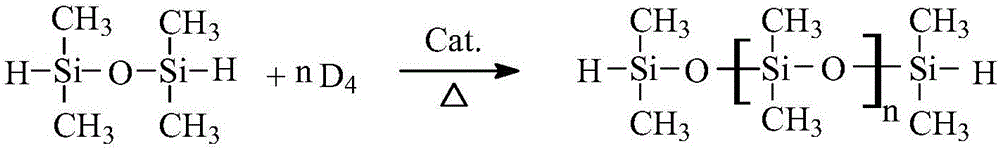

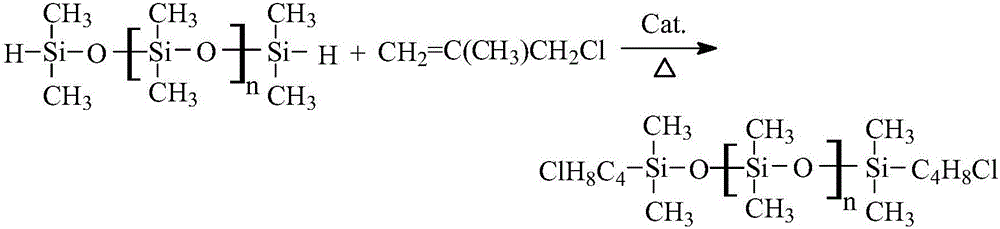

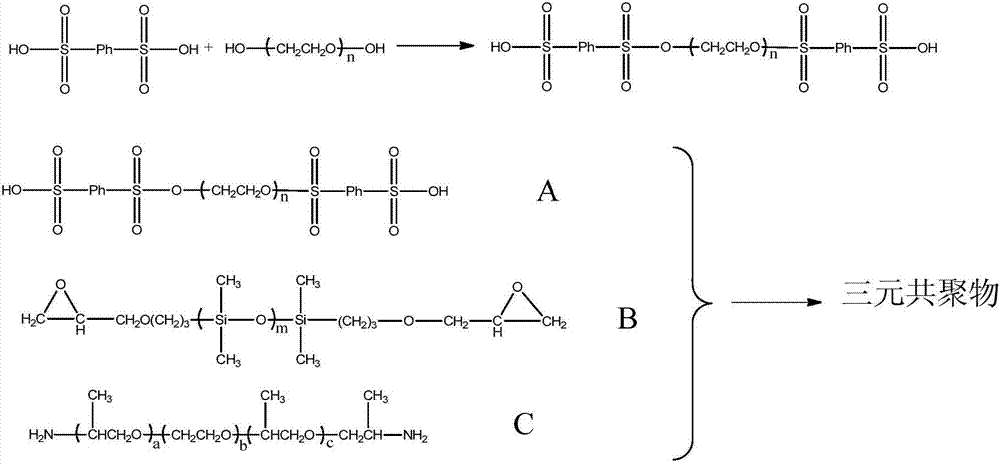

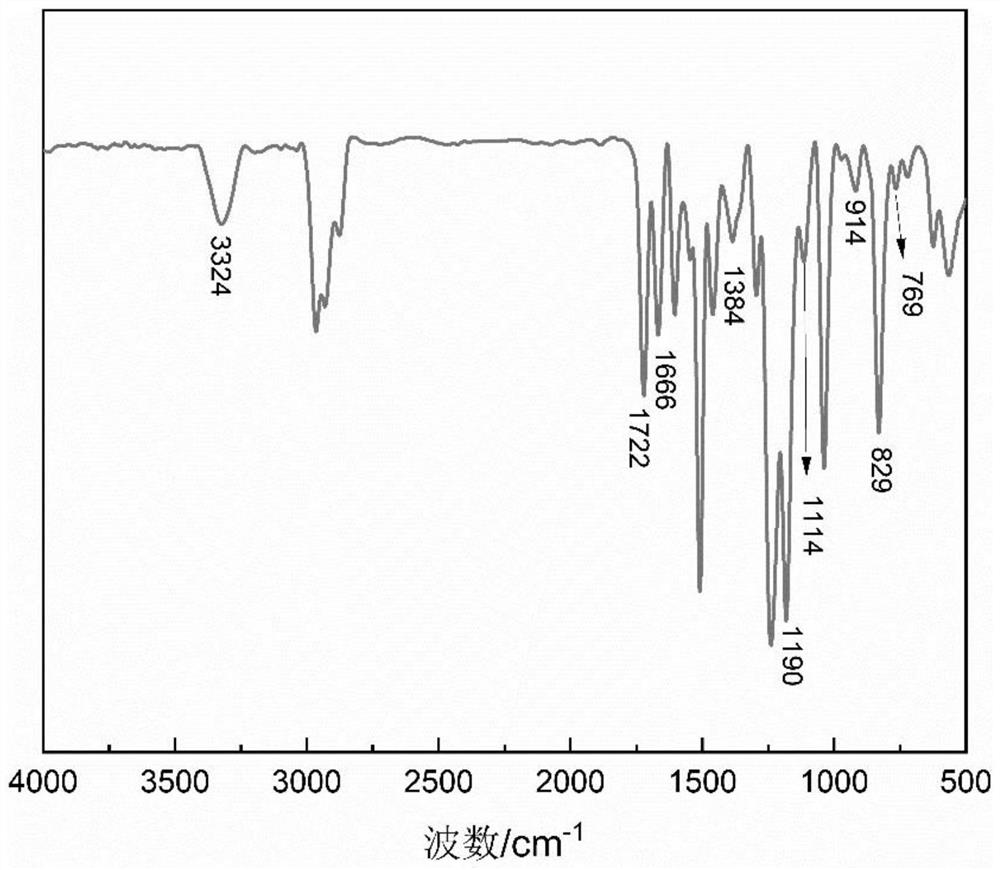

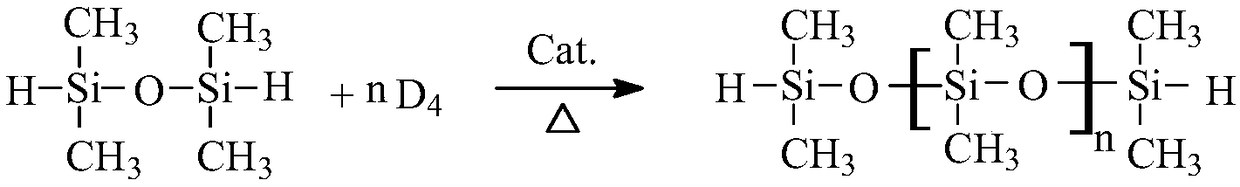

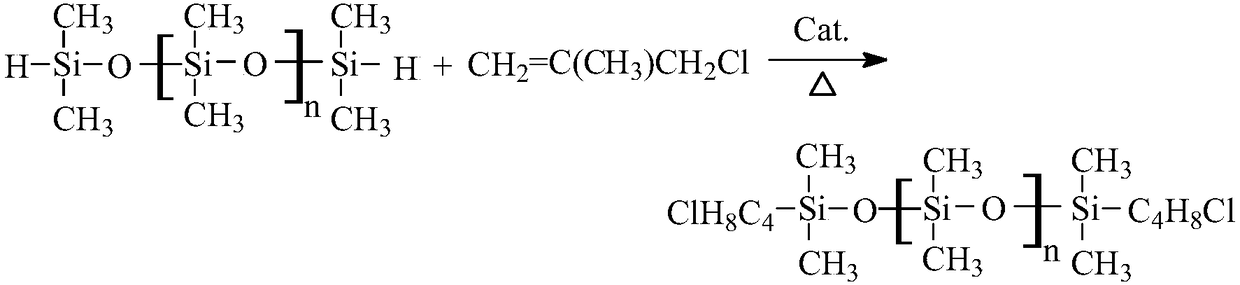

Preparation method for anionic linear copolymerized organic silicon softening and finishing agent

The invention discloses a preparation method for anionic linear copolymerized organic silicon softening and finishing agent. Under the conditions of high salinity and high alkalinity, cationic groups playing the function of stabilization in the structure of the organic silicon softening and finishing agent are easily flocculated with a dye dispersant, the stability of emulsion is broken, and phenomena like breaking of emulsion and floating of oil are generated. The method comprises organic silicon macromolecule chain extension reaction of 1,1,3,3-tetramethyl disiloxane, addition reaction of 3-chloro-2-methylpropene and terminated hydrogen-containing silicone oil, preparation of terminated chlorine-containing and side-chain hydrogen-containing silicone oil, addition reaction of olefin acid and side-chain hydrogen-containing silicone oil, ammonolysis of an organosilicone macromolecular chain segment, preparation of terminated epoxy-containing polyether, and condensation polymerization of the organosilicone macromolecular chain segment and a polyether chain segment. According to the method, the organosilicone chain segment is subjected to anion modification, the compatibility of the emulsion to anions is improved, the introduction of the anions also greatly improves the high temperature resistance, salt tolerance, alkaline resistance properties of the emulsion, and the product can be suitable for dyeing one-bath processing.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +1

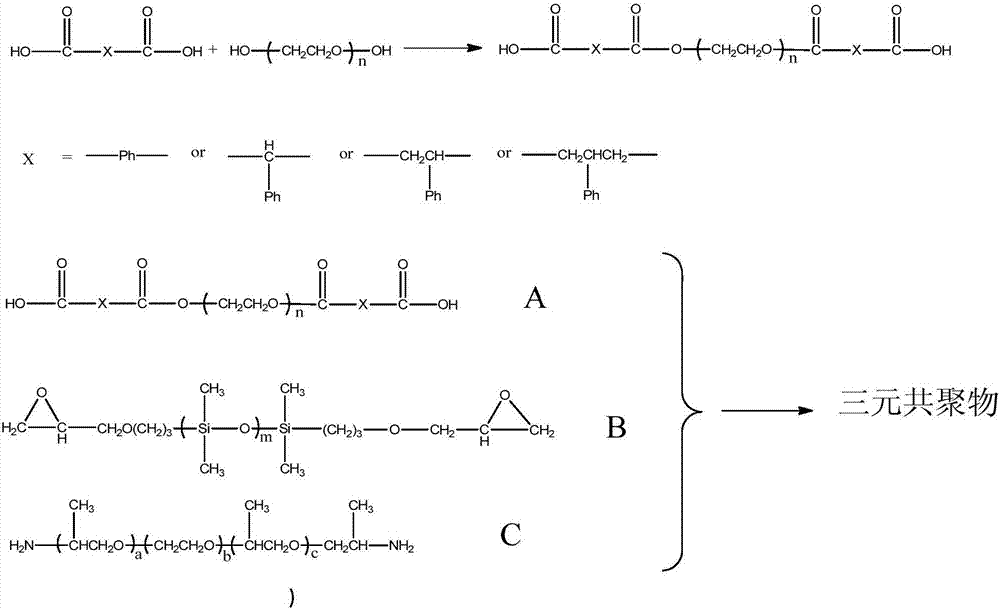

Preparation method of organosilicone ternary block copolymer

InactiveCN106883417AImprove hydrophilicityImprove performanceLiquid repellent fibresGrip property fibresOrganic acidAlcohol

The invention discloses a preparation method of an organosilicone ternary block copolymer. The traditional amino silicon oil softening agent has the problems of poor hydrophilicity, easiness in demulsification, floating oil, roll sticking and the like. The method comprises the steps of enabling aromatic polybasic carboxylic acid to react with a terminal hydroxyl polyethylene glycol under nitrogen protection at 140-160 DEG C for 10-14h to obtain corresponding aromatic organic acid macrogol ester; adding epoxy silicone oil and polyether polyamine to the product, adding a proper amount of catalyst employing monohydric alcohol of C1-C4 as a medium, heating the mixture to 80-90 DEG C and reacting for 24-40h to obtain the organosilicone ternary block copolymer after reaction is completed. Excellent hydrophilicity is provided while a fabric is endowed with an excellent soft and fluffy handle when the prepared copolymer is used for fabric softening.

Owner:传化智联股份有限公司 +1

Preparation method of water-based chloroethylene/isobutyl vinyl ether copolymer dispersion

ActiveCN102181006AHas "self-emulsifying" propertiesReactiveVolatile organic compoundButyl vinyl ether

The invention discloses a preparation method of water-based chloroethylene / isobutyl vinyl ether copolymer dispersion. 60 to 75 mass percent of chloroethylene monomer, 25 to 40 mass percent of isobutyl vinyl ether monomer, acrylic hydroxyalkyl ester or the monomer of the same kind in an amount which is 5 to 15 percent of the total mass of the chloroethylene and the isobutyl vinyl ether, and unsaturated carboxylic acid monomer in an amount which is 10 to 25 percent of the total mass of the chloroethylene and the isobutyl vinyl ether are used as raw materials; and the water-based chloroethylene / isobutyl vinyl ether copolymer dispersion is obtained by polymerization reaction, neutralization reaction, aqueous phase dispersion treatment and organic solution removal in organic solvent, initiator and organic amine neutralizer. The dispersion has low volatile organic compound (VOC) content, environmental friendliness and good cohesiveness, and is particularly suitable for producing water-based coating, water-based adhesive and water-based ink.

Owner:江苏利思德新材料股份有限公司

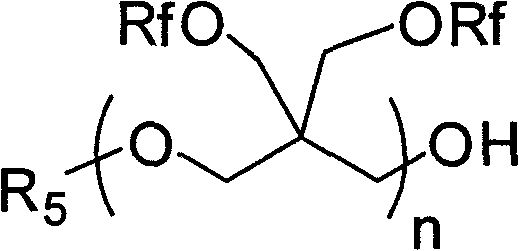

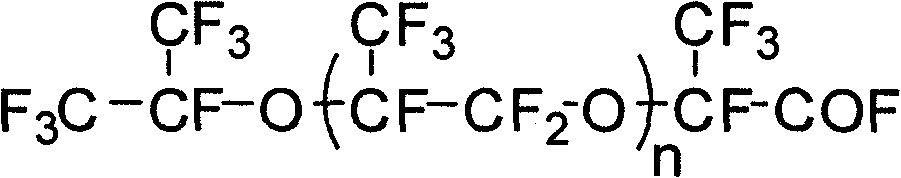

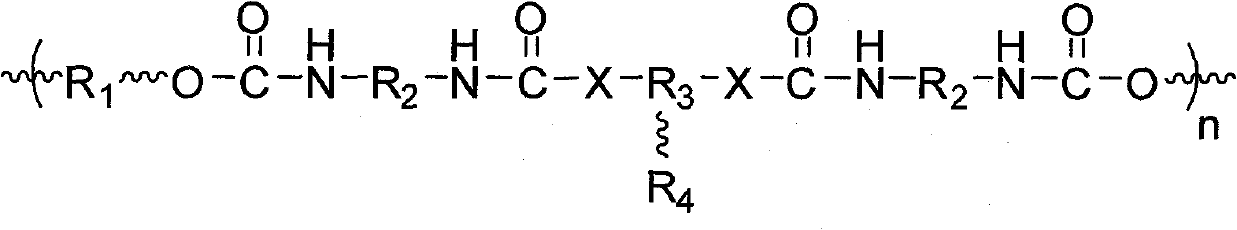

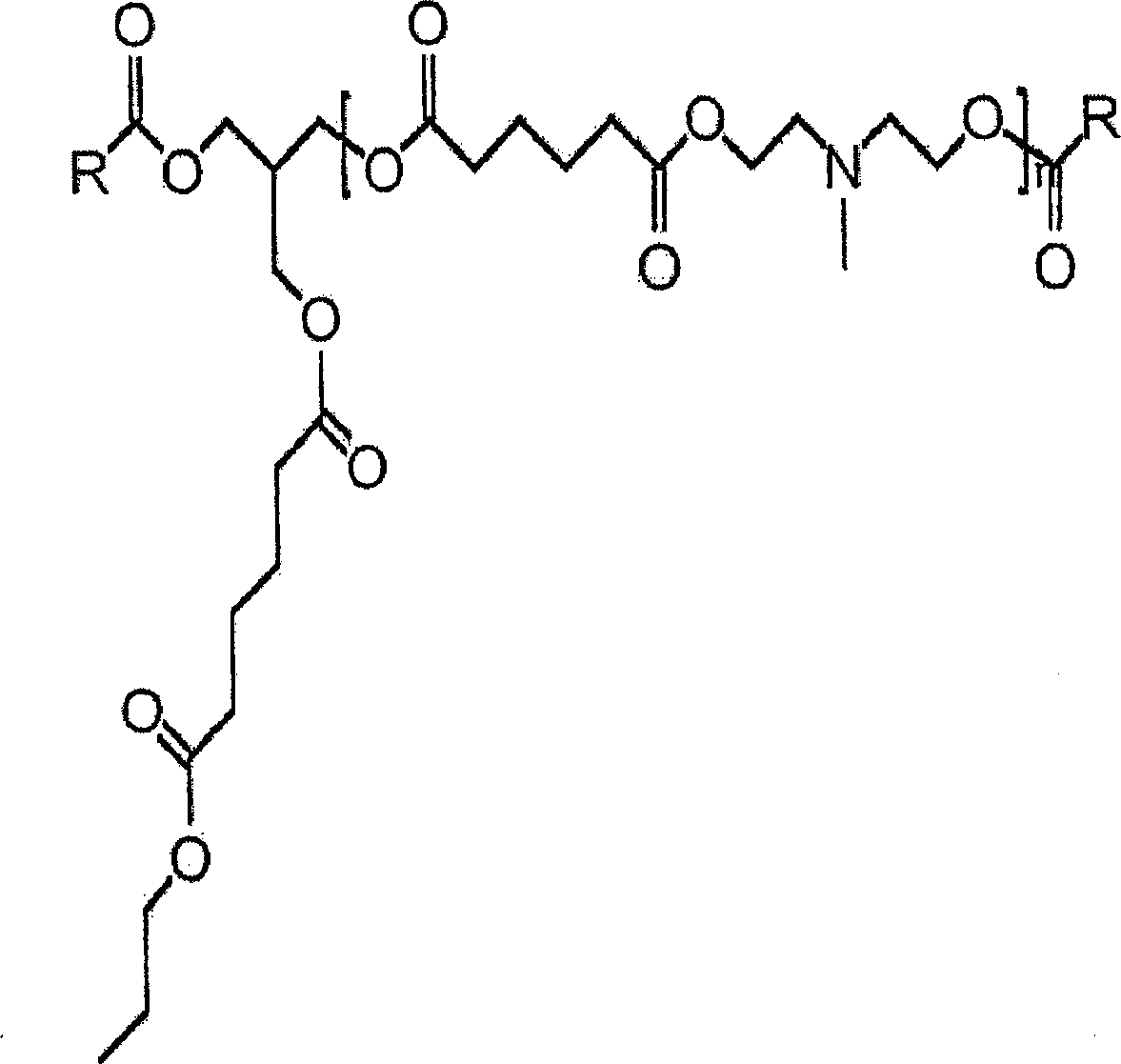

Fluorine-containing polyether graft modified aqueous polyurethane and preparation and application thereof

InactiveCN101157750BHas self-emulsifying propertiesNo emissionsOther chemical processesPolymer sciencePolyol

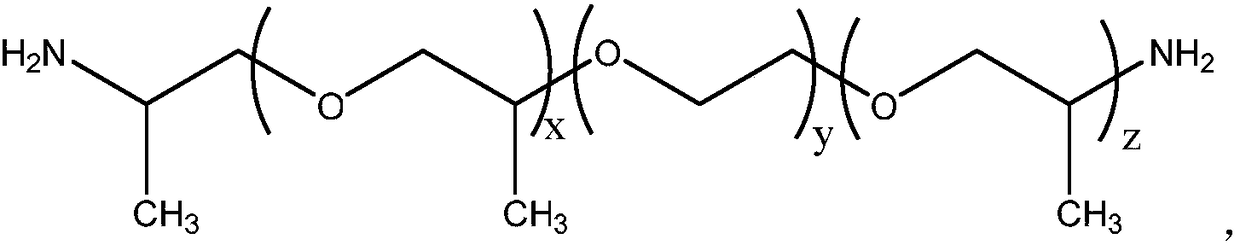

The present invention relates to a fluorine-containing polyether grafting modified waterborne polyurethane, the preparation and the application thereof, a structural general formula of polyurethane is as the formula, wherein, R1 is equal to a polyurethane soft-segment polyol structure, R2 is equal to a polyurethane hard-segment isocyanate structure, R3 is equal to a polyurethane hard-segment chain extender structure, R4 is equal to the fluorine-containing polyether; X is equal to NH and O; the preparation is that: the polyol and the isocyanate react to compound the polyurethane prepolymer, then the waterborne polyurethane are obtained through the chain propagation of a chain extender, then the waterborne polyurethane and the fluorine-containing polyether are carried out a grafting reaction in the big molecules, so as to synthesize the fluorine-containing polyether grafting modified waterborne polyurethane; the application is that: the present invention can be applied to aerospace, aviation, automobiles, electronics, textiles, carpets, leathers, paper making, packaging, washing, machinery, construction and other fields. The present invention adopts the water as the solvent and has no formaldehyde, no or low VOC emission, no bioaccumulation and no toxicity, which is a multifunctional, green, environment protective, water-proof and dirt-proof coating layer and fabric finishing agent.

Owner:DONGHUA UNIV

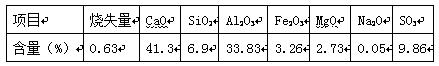

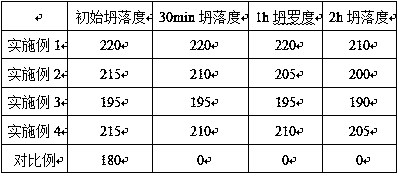

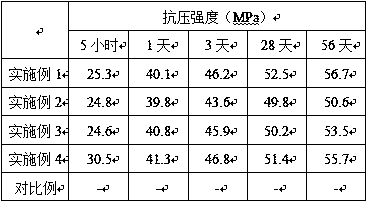

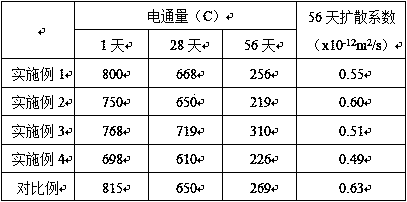

High corrosion resistant marine cement cementing material and preparation method thereof

The invention relates to the construction field, and in particular relates to a high corrosion-resistant marine cement cementing material and a preparation method thereof, and the high corrosion-resistant marine cement cementing material comprises 20-25 parts of wollastonite; 80-100 parts of sulphoaluminate cement; 30-50 parts of nano-like hydrotalcite; 20-30 parts of fiber; 80-100 parts of coralreef sand; 50-60 parts of polyacrylamide; 20-30 parts of modified acrylic emulsion and 10-15 parts of additives; the invention aims to overcome the defects of the prior art and provide the high corrosion-resistant marine cement cementing material and the preparation method thereof. The high corrosion-resistant marine cement cementing material has the characteristics of good mechanical strength, durability and corrosion resistance, improved bending strength, improved cement density, better flocculation property, capability of reducing friction resistance between liquids, excellent impermeability, quick hardening, early strength, high later strength and the like.

Owner:广西云燕特种水泥建材有限公司

Admixture for marine engineering concrete and preparation method of admixture

The invention relates to the field of buildings, in particular to an admixture for marine engineering concrete and a preparation method of the admixture. The admixture is prepared from raw materials in parts by weight: 100-150 parts of a water reducing agent, 0.5-1 part of tetramethylammonium iodide, 1-5 parts of sodium ethoxide, 3-5 parts of polyacrylamide, 30-50 parts of a surfactant, 15-20 parts of a rust inhibitor, 30-50 parts of an expansion agent, 3-5 parts of a retarder, 6-10 parts of a deforming agent and 0-80 parts of water. The invention aims to overcome the shortcomings of the priorart and provide the admixture for the marine engineering concrete and the preparation method of the admixture, the effects of water reduction, rust resistance, defoaming and retarding are achieved, and the effects are improved; the admixture is added into the concrete, so that the flowability of concrete slurry is improved, retentivity is good, the water reduction rate is high, the density of theconcrete is improved, good flocculability is achieved, and the friction resistance between liquid can be reduced; and the grinding efficiency is improved, and the admixture has the characteristics ofexcellent anti-permeability, fast hardening and early strength, high later strength and the like.

Owner:广西云燕特种水泥建材有限公司

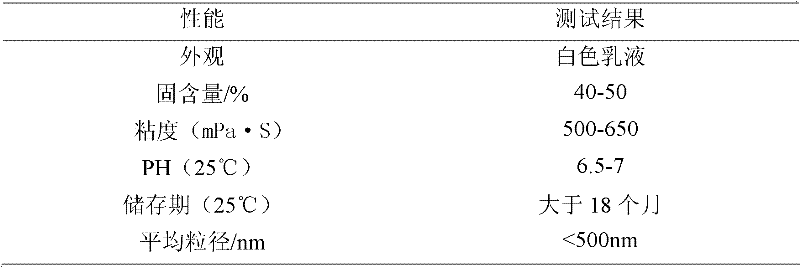

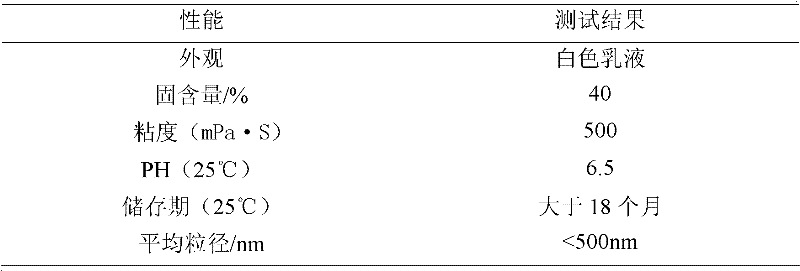

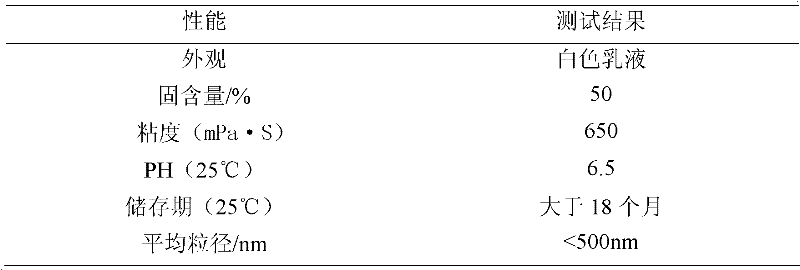

Polyurethane-urea modified self-emulsifying nano water-based epoxy emulsion and preparation method thereof

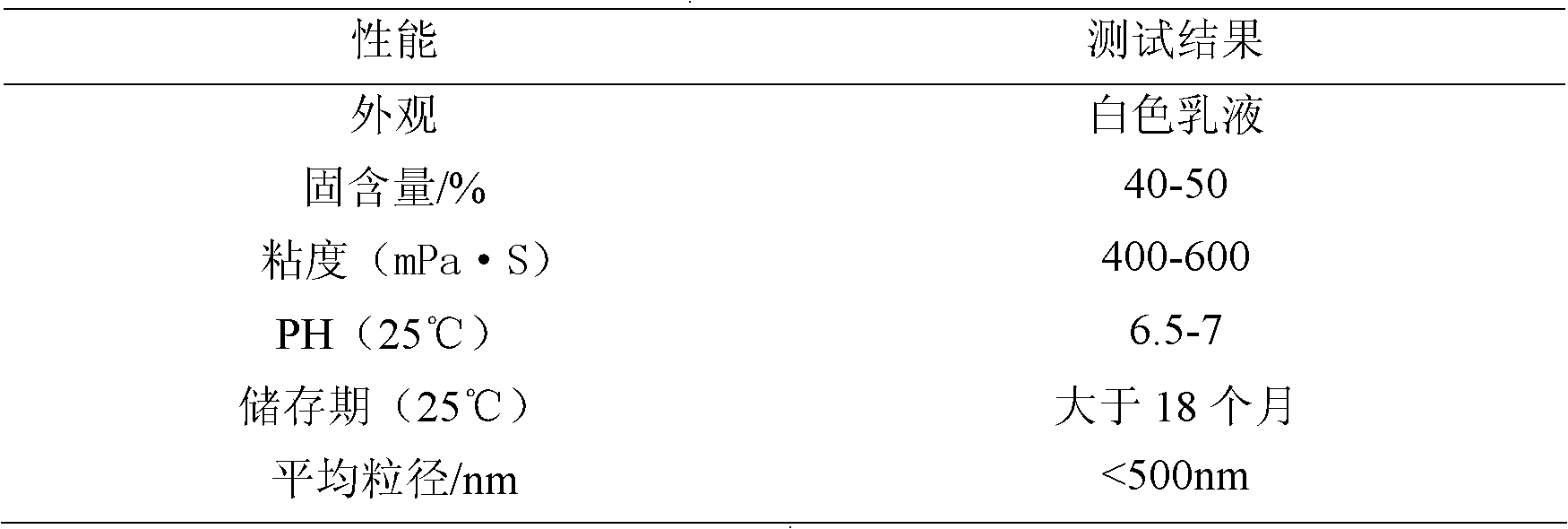

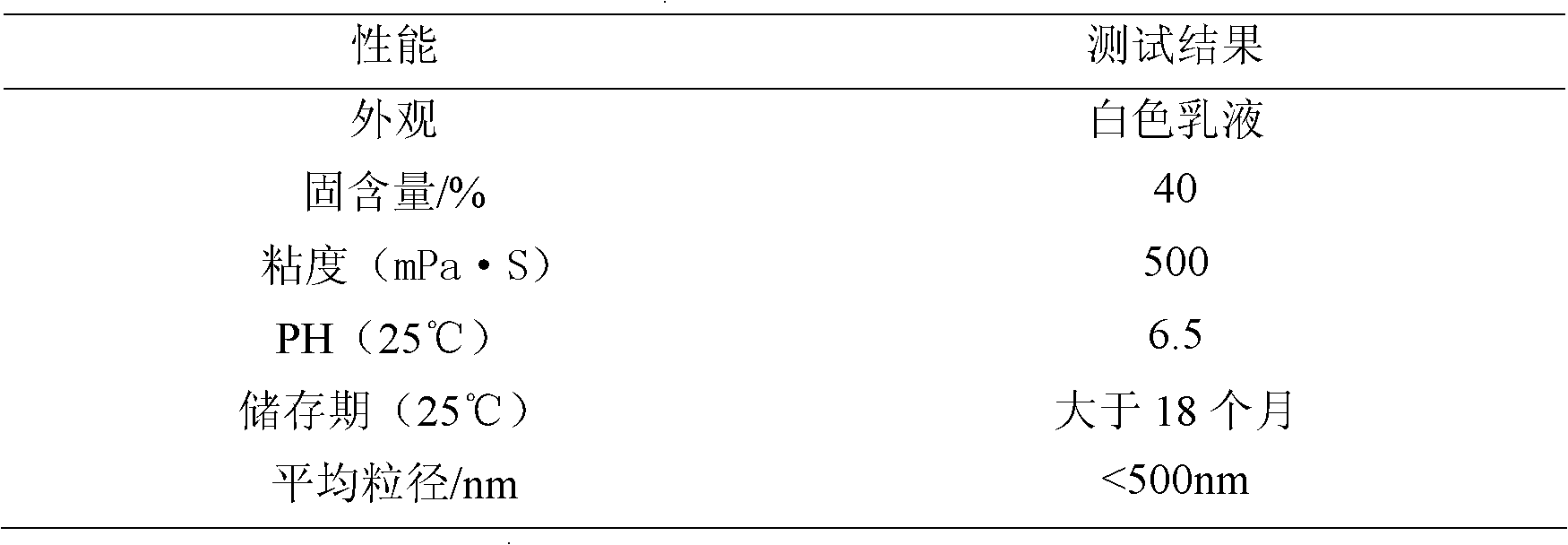

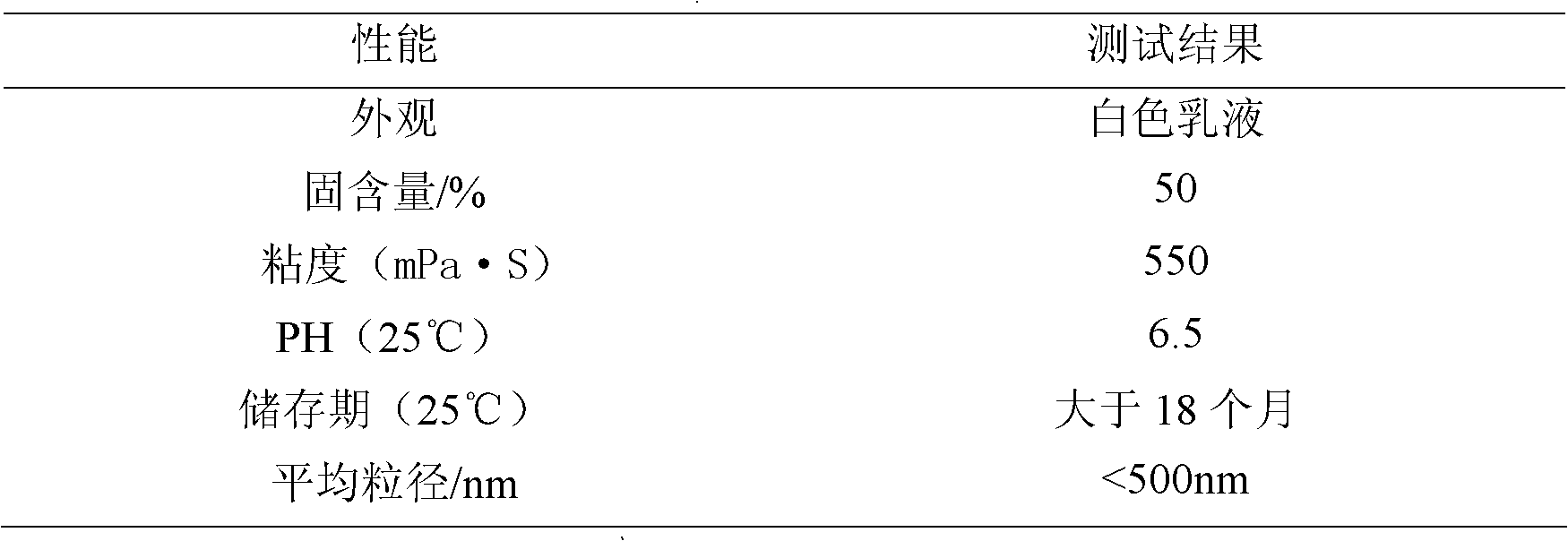

ActiveCN102295735AUniform particle sizeImprove performancePolyurea/polyurethane coatingsEmulsionOrganic solvent

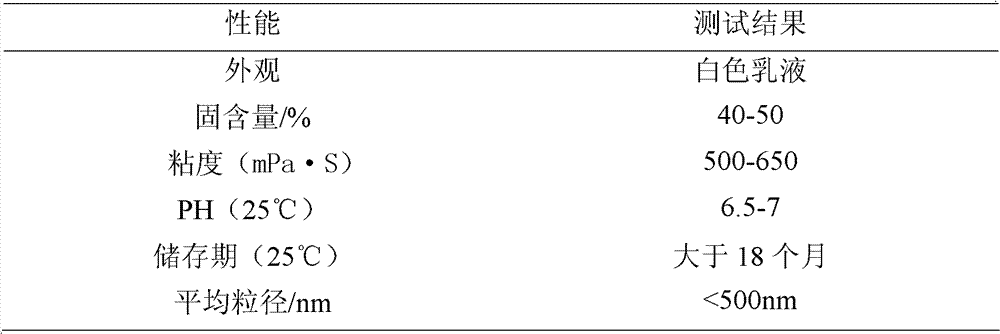

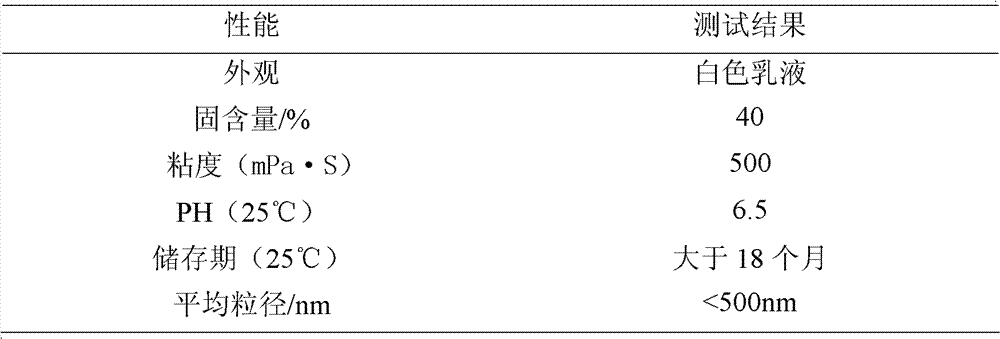

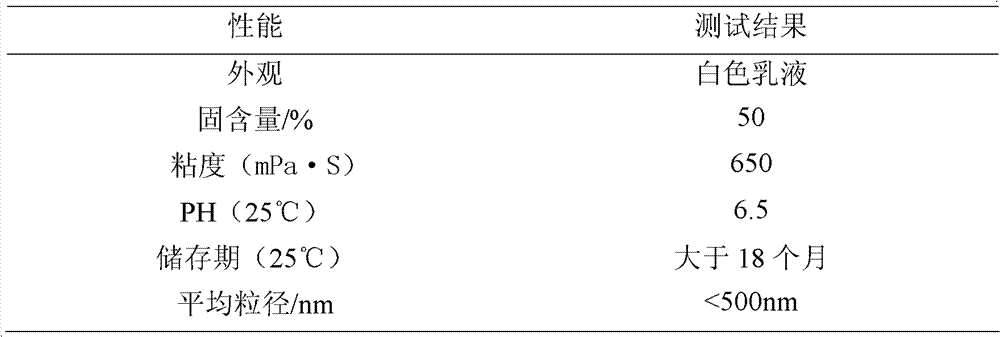

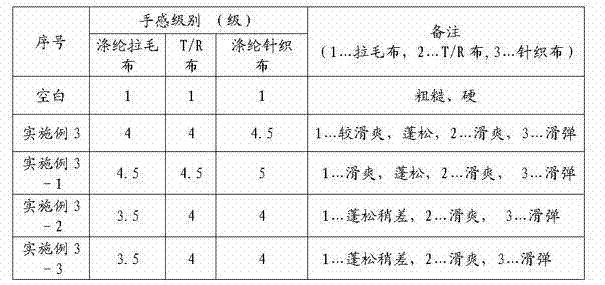

The invention relates to polyurethane-urea modified self-emulsifying nanometer waterborne epoxy emulsion and a preparation method thereof. The emulsion has solid content of 40-50%, an average particle size of less than 500nm and a viscosity of 500-650(mPa*S). A chain segment in the self-emulsifying nanometer waterborne emulsion of the invention is introduced with a compound containing a nonionic hydrophilic chain segment, so that epoxy resin can have a self-emulsifying property, and the corrosion resistance and curing time of a coating can be improved by the polyurethane-urea based chain segment.A water dispersion system formed by the modified epoxy resin is then subjected to high pressure emulsification by a homogenizer and the particle size is dispersed to a nanoscale, and after a long time storage, physicochemical properties change little. Thus, the emulsion of the invention has good stability. The synthesis process of the method provided in the invention adds no organic solvent and has simple operation, thus being easy to realize.

Owner:TIANJIN UNIV

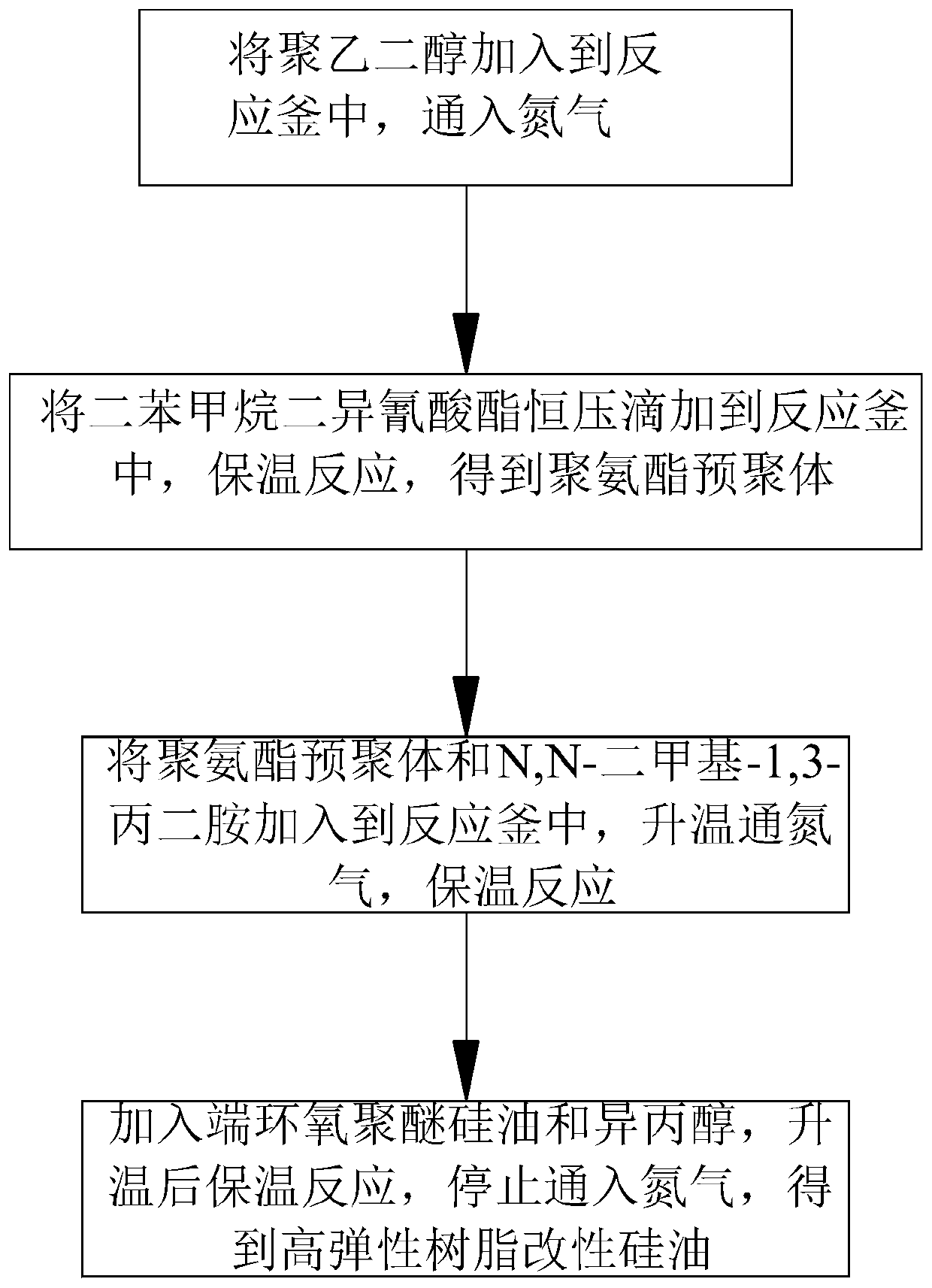

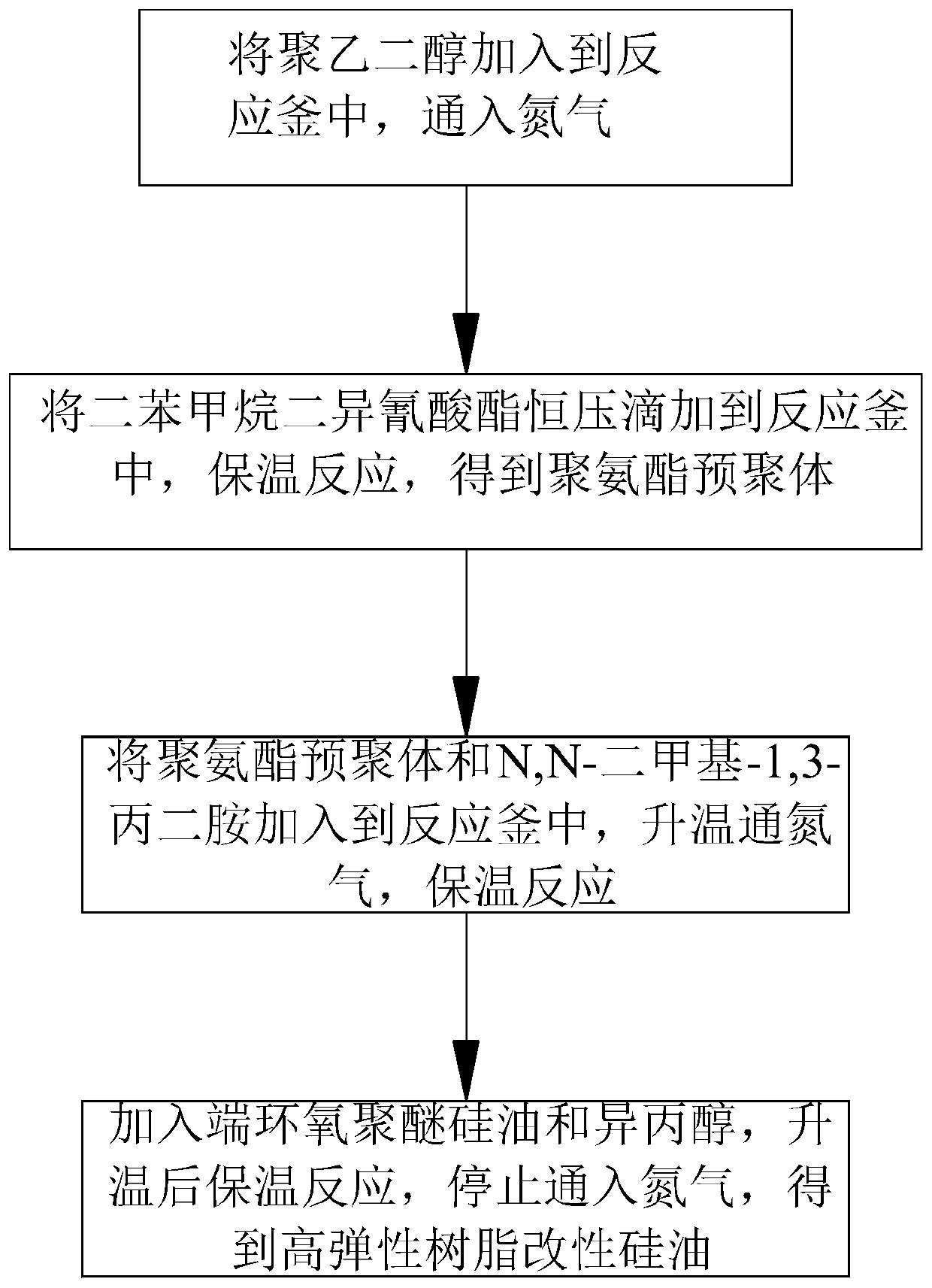

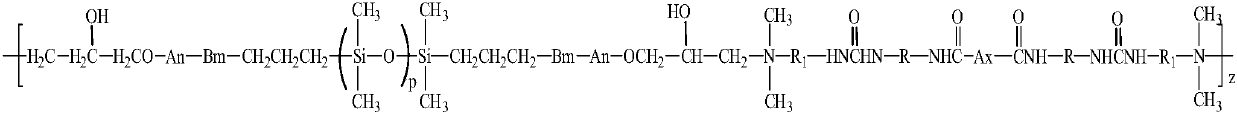

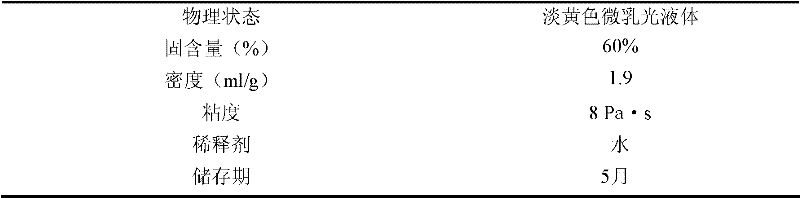

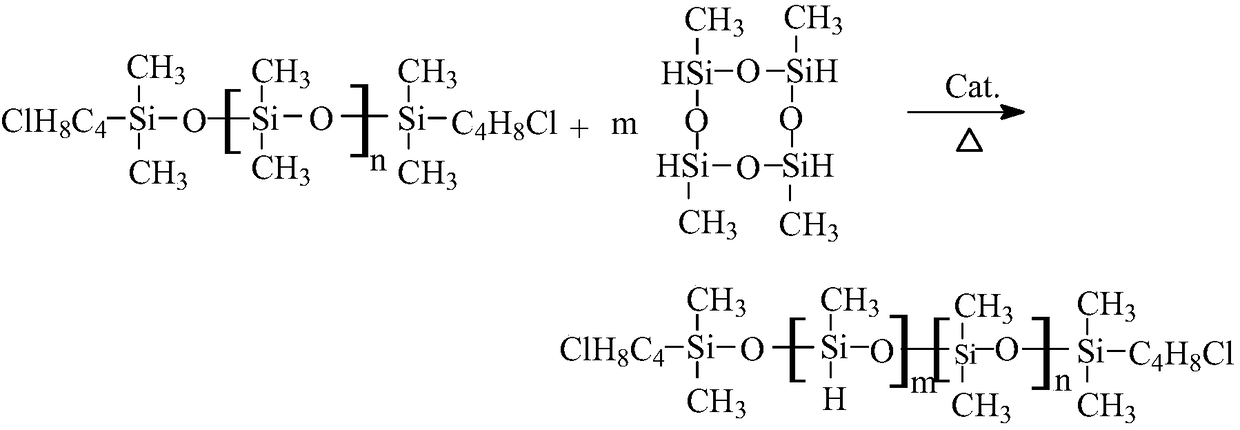

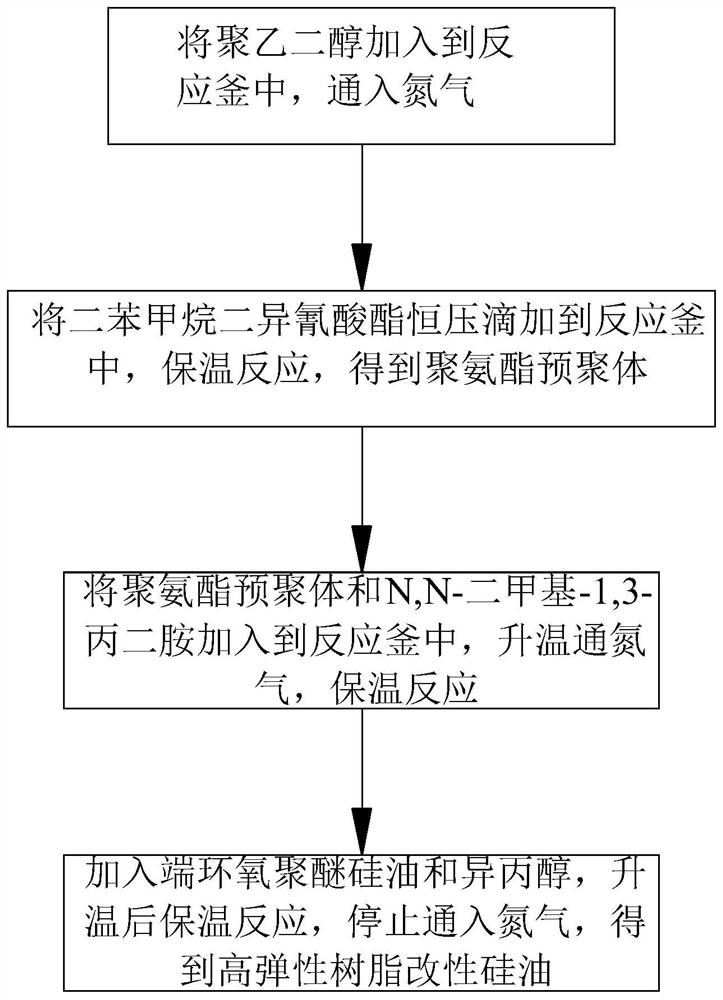

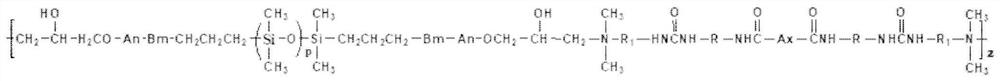

High-elasticity resin modified silicone oil and preparation method thereof

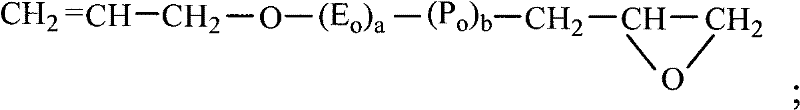

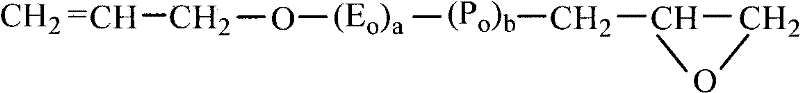

ActiveCN111171267AGood film formingAdvantage bulkinessGrip property fibresPolymer scienceHigh activity

The invention discloses high-elasticity resin modified silicone oil. The invention relates to the field of fine chemical synthesis, in particular to a high-molecular polymer, which has the main structural general formula shown as the specification, wherein A is CH2CH2O, B is a group represented as the specification, R1 is CH2CH2CH2, R is m, n, p, z, x is an integer, 3 < = x < = 5, 2 < = m < = 4, 5< = n < = 7, 105 < = p < = 145, and 2 < = z < = 4. According to the invention, a polyurethane material has a soft and hard chain segment block structure, so that the high-elasticity resin modified silicone oil is developed on the basis of the principle that the silicone oil has high elasticity and can endow a material with high elasticity, high-activity polyurea elastic resin with a soft and hardblock structure is connected on the basis of an organic silicon soft chain segment; the high-elasticity resin modified silicone oil structurally has a soft-hard chain segment, so that the high-elasticity resin modified silicone oil has a better treatment effect on fabric treatment compared with other silicone oil.

Owner:NINGBO RUNHE HIGH TECH MATERIAL CO LTD

Preparation method for waterborne polyurethane modified epoxy resin curing agent

InactiveCN101824133BImprove featuresHas self-emulsifying propertiesEpoxy resin coatingsEpoxyPolymer science

The invention relates to a preparation method for a waterborne polyurethane modified epoxy resin curing agent. The preparation method comprises the following steps: adding catalyst boron trifluoride ether to a polyethylene glycol, then adding epoxy resin, stirring and heating the mixture for some time to prepare modified epoxy resin with epoxy groups at both ends; dripping monoepoxy compound 501 to diethylenetriamine according to an equal molar ratio to prepare a blocking product; reacting the obtained modified epoxy resin with bisepoxy compound 128 and polyurethane prepolymer by mixing to prepare polyurethane modified diepoxide; dripping the prepared polyurethane modified diepoxide to the prepared blocking product to obtain an addition product; and neutralizing the addition product into a salt by dripping glacial acetic acid, and then adding water to prepare the waterborne polyurethane modified epoxy resin curing agent. By introducing the epoxy resin, the invention enables the paint film obtained after curing to have superior water resistance, solvent resistance, chemical resistance and flexibility, thereby achieving the fine characteristics of the polyurethane, and overcoming the disadvantages of the epoxy resin.

Owner:TIANJIN UNIV

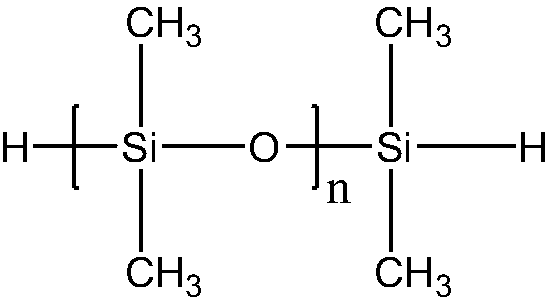

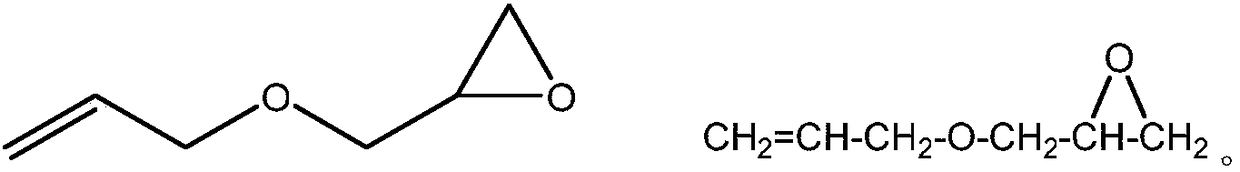

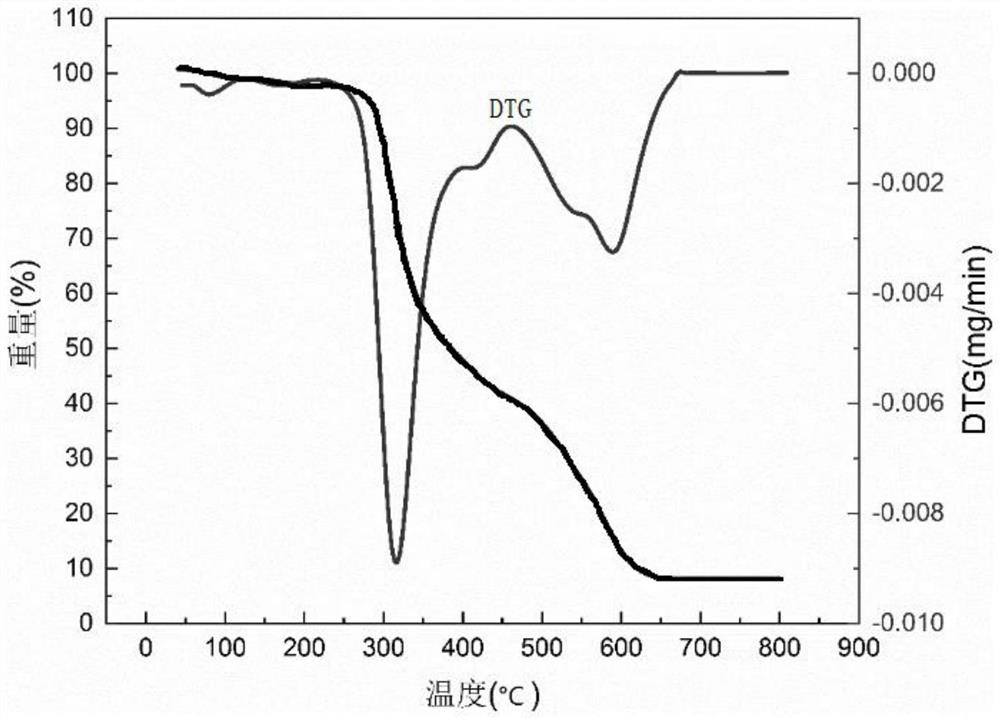

Low-solvent synthesis method for terpolymer block silicone oil

The invention provides a low-solvent synthesis method for terpolymer block silicone oil. The method is characterized by comprising the following steps: 1) adding hydrogen-terminated silicone oil withmolecular weight of 13,000-15,000 to a reaction container, and performing heating to about 80-90 DEG C while performing stirring; 2) adding allyl glycidyl ether and a catalyst chloroplatinic acid, performing heating, keeping the temperature at 115-126 DEG C, and performing a reaction for about 2 h; 3) adding polyether amine ED-2003, adding 2-methyl 2,4-pentanediol and ethylene glycol monobutyl ether simultaneously, performing a reaction at 140-150 DEG C for 6-8 h, and adjusting pH to 6-7 with glacial acetic acid to obtain the product. A mixed solvent consisting of 2-methyl 2,4-pentanediol andethylene glycol monobutyl ether is used, the quantity of solvents used in synthesis is reduced, the hydrogen-terminated silicone oil with molecular weight of 13,000-15,000 and polyether amine ED-2003are used for synthesis, and excellent handfeel is achieved.

Owner:JIANGSU NIMATE SCI & TECH CO LTD

Aqueous woodenware paint

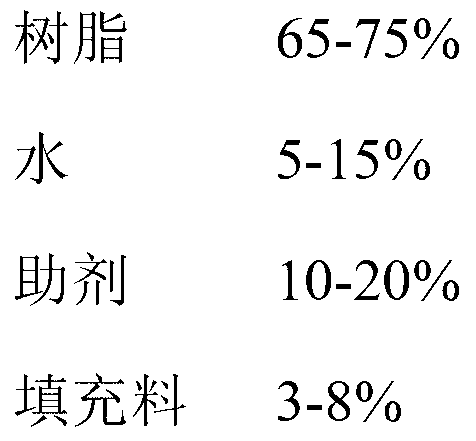

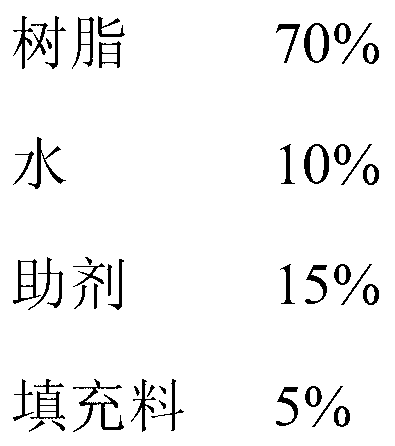

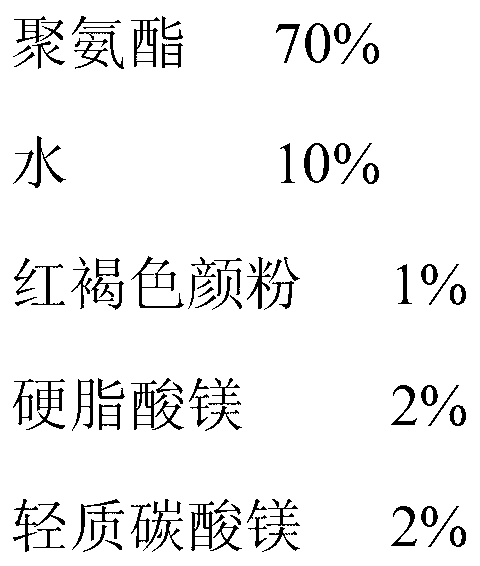

InactiveCN103224749AHas self-emulsifying propertiesHigh strengthPolyurea/polyurethane coatingsLacquerNuclear chemistry

The invention provides an aqueous woodenware paint, which comprises the following ingredients by weight percent: resin 65-75%, water 5-15%, auxiliary agents 10-20% and fillers 3-8%, and the ingredients above are nontoxic materials which are friendly to environment and are harmless to human body.

Owner:江门市联益精细化工有限公司

High temperature resistant self-crosslinking waterborne epoxy resin for oil well cement

The invention discloses a high-temperature-resistant self-crosslinking water-based epoxy resin for oil well cement. The preparation method steps are as follows: (1) dissolving the epoxy resin in N,N-dimethylformamide, feeding in nitrogen, and stirring Heat up to 85°C; (2) Dissolve benzoyl peroxide in acetone, then add the acetone solution dropwise to the solution in step (1), raise the temperature to 95°C, and keep the temperature constant for 30 minutes; (3) Add to the reaction solution Slowly add a mixed aqueous solution of 2-acrylamido-2-methylpropanesulfonic acid and acrylamide; constant temperature reaction for 4h; (4) rotary evaporation to remove solvent, use ethyl acetate to repeatedly wash to remove unreacted epoxy resin raw material, to obtain Self-crosslinking waterborne epoxy resin. The self-crosslinking water-based epoxy resin of the invention is added to the cement to simplify the on-site slurry mixing step; it can improve the brittleness characteristics of the oil well cement stone, and effectively improve the macroscopic mechanical properties and compactness of the oil well cement stone.

Owner:SOUTHWEST PETROLEUM UNIV

Self-emulsified aqueous epoxy emulsion and method for preparing same

The present invention provides one kind of self-emulsifying water thinned epoxy emulsion and its production process. The self-emulsifying water thinned epoxy emulsion is produced through emulsion copolymerization with the polymer intermediate, which is obtained through polymerizing the mixed organosilicon monomer comprising alkenyl-containing trimethyl silane and octalkyl cyclotetrasiloxane and acrylic acid monomer, epoxy resin and acrylic acid monomer. The self-emulsifying water thinned epoxy emulsion has homogeneous particle size, high stability, and stable production process. The anticorrosive paint compounded with the self-emulsifying water thinned epoxy emulsion reaches the level of solvent type epoxy resin paint.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

High-temperature-resistant self-cross-linking waterborne epoxy resin for oil well cement

The invention discloses a high-temperature-resistant self-cross-linking water-borne epoxy resin. The preparation method comprises the following steps: (1) dissolving an epoxy resin in N, N-dimethylformamide, introducing nitrogen, stirring and heating to 85 DEG C; (2) dissolving benzoyl peroxide in acetone, dropwise adding the acetone solution into the solution obtained in the step (1), heating to 95 DEG C, and keeping the temperature for 30 minutes; (3) slowly adding a mixed aqueous solution of 2-acrylamido-2-methylpropanesulfonic acid and acrylamide into the reaction solution, and performing constant-temperature reaction for 4 hours; and (4) carrying out rotary evaporation to remove the solvent, and repeatedly washing with ethyl acetate to remove the unreacted epoxy resin raw material to obtain the self-cross-linking waterborne epoxy resin. According to the invention, the self-cross-linking water-borne epoxy resin is added into cement, so that the on-site slurry preparation step is simplified; and the brittleness characteristic of the oil well set cement can be improved, and the macroscopic mechanical property and compactness of the oil well set cement are effectively improved.

Owner:SOUTHWEST PETROLEUM UNIV

A kind of preparation method of anionic linear copolymerization organosilicon softening agent

The invention discloses a preparation method for anionic linear copolymerized organic silicon softening and finishing agent. Under the conditions of high salinity and high alkalinity, cationic groups playing the function of stabilization in the structure of the organic silicon softening and finishing agent are easily flocculated with a dye dispersant, the stability of emulsion is broken, and phenomena like breaking of emulsion and floating of oil are generated. The method comprises organic silicon macromolecule chain extension reaction of 1,1,3,3-tetramethyl disiloxane, addition reaction of 3-chloro-2-methylpropene and terminated hydrogen-containing silicone oil, preparation of terminated chlorine-containing and side-chain hydrogen-containing silicone oil, addition reaction of olefin acid and side-chain hydrogen-containing silicone oil, ammonolysis of an organosilicone macromolecular chain segment, preparation of terminated epoxy-containing polyether, and condensation polymerization of the organosilicone macromolecular chain segment and a polyether chain segment. According to the method, the organosilicone chain segment is subjected to anion modification, the compatibility of the emulsion to anions is improved, the introduction of the anions also greatly improves the high temperature resistance, salt tolerance, alkaline resistance properties of the emulsion, and the product can be suitable for dyeing one-bath processing.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +1

A kind of highly elastic resin modified silicone oil and preparation method thereof

ActiveCN111171267BGood film formingHas self-emulsifying propertiesGrip property fibresPolymer scienceHigh activity

The invention discloses a highly elastic resin modified silicone oil, which relates to the field of fine chemical synthesis, and its main structural formula is, wherein, A is CH 2 CH 2 O, B for R 1 for CH 2 CH 2 CH 2 , R is m, n, p, z, x is an integer, and 3≤x≤5, 2≤m≤4, 5≤n≤7, 105≤p≤145, 2≤z≤4. By adopting the above-mentioned technical scheme, the present invention is mainly based on the principle that the polyurethane material has a soft and hard segment block structure, which can endow the material with high elastic performance. Highly active polyurea elastic resin has been developed into highly elastic resin modified silicone oil, which has a soft-hard segment in its structure, which endows it with a better treatment effect in fabric treatment than other silicone oils.

Owner:NINGBO RUNHE HIGH TECH MATERIAL CO LTD

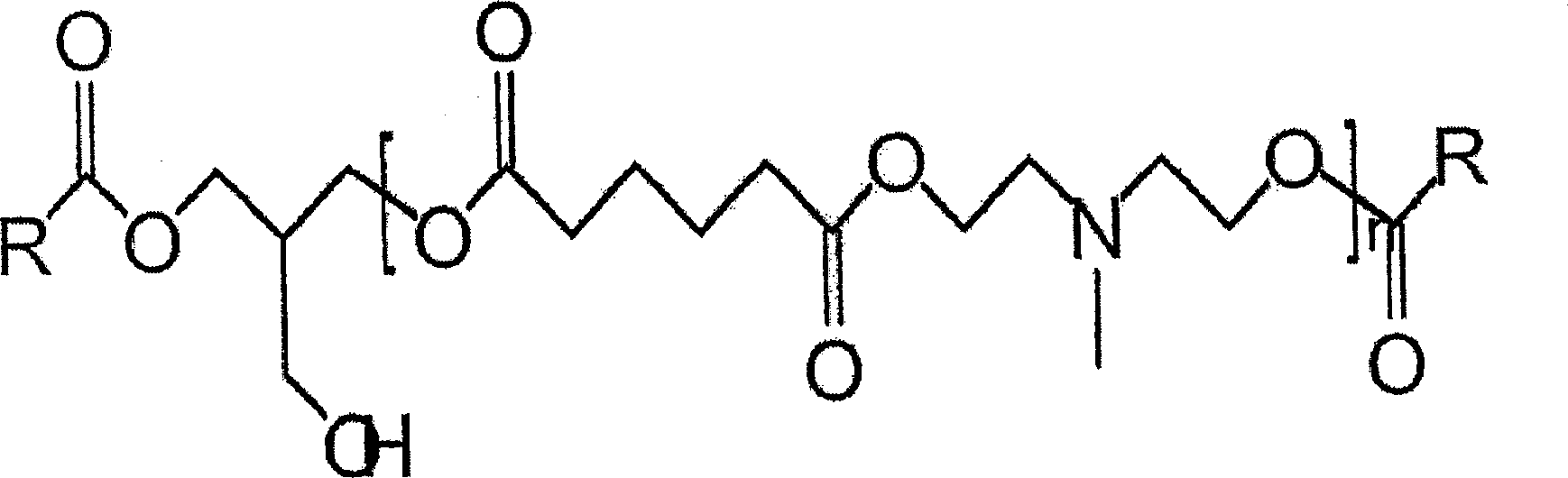

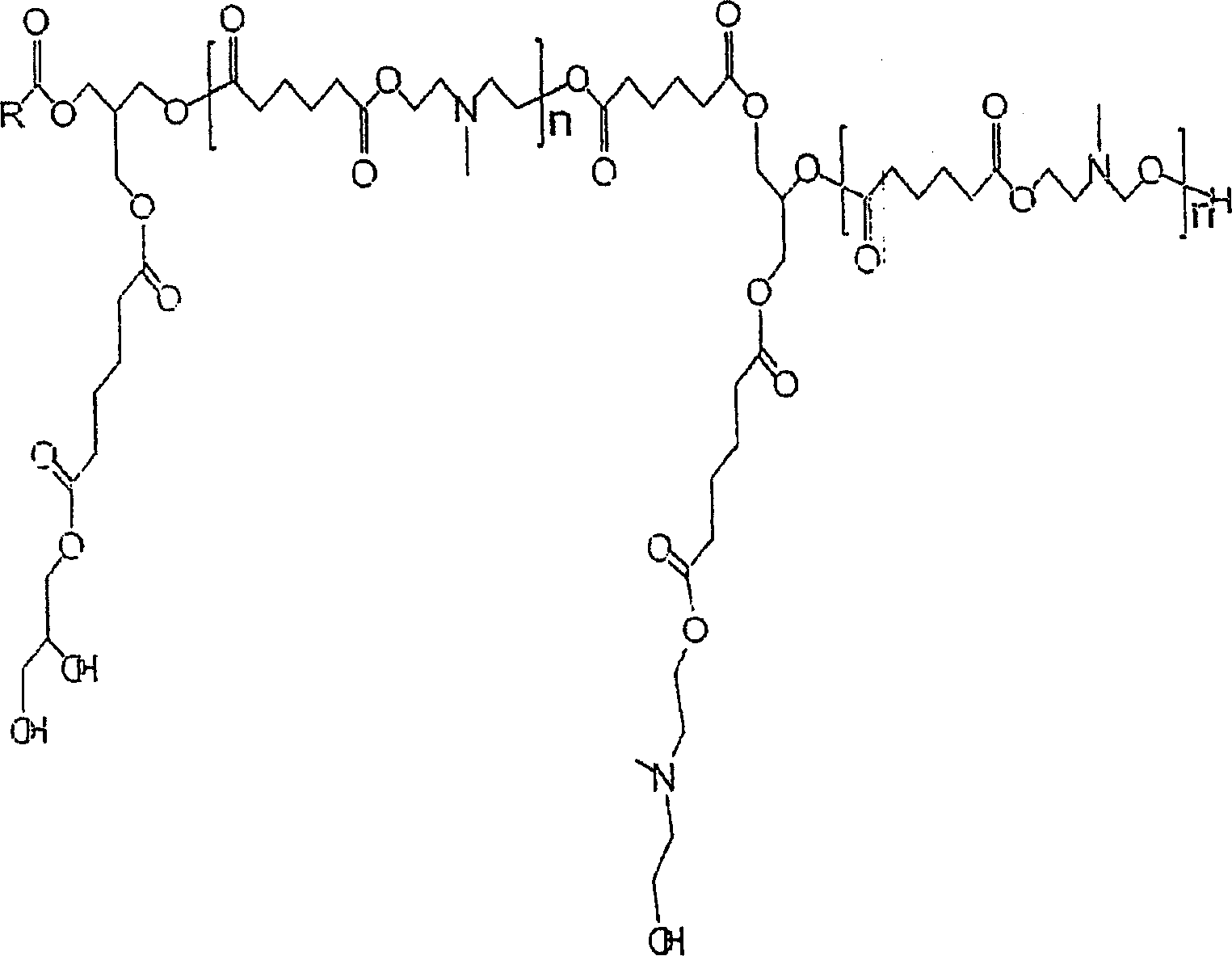

Tertiary amine functional complex polyester polymers and methods of production and use

InactiveCN1764464AImprove the lubrication effectPromote degradationCosmetic preparationsOrganic active ingredientsPolyesterAlcohol

A polyesteramine comprises at least one tertiary amine group, at least one ester linkage and at least one alkyl chain. It is produced by reacting at least one tertiary amine functional polyol, at least one polyfunctional carboxylic acid and at least one monofunctional carboxylic acid or monofunctional alcohol. The polyesteramine can be used in cosmetic and lubricant applications as a result of its substantivity and lubricity properties.

Owner:INOLEX INVESTMENT CORP

Preparation method of water-based chloroethylene/isobutyl vinyl ether copolymer dispersion

ActiveCN102181006BHas "self-emulsifying" propertiesDispersion size is smallWater basedOrganic solvent

The invention discloses a preparation method of water-based chloroethylene / isobutyl vinyl ether copolymer dispersion. 60 to 75 mass percent of chloroethylene monomer, 25 to 40 mass percent of isobutyl vinyl ether monomer, acrylic hydroxyalkyl ester or the monomer of the same kind in an amount which is 5 to 15 percent of the total mass of the chloroethylene and the isobutyl vinyl ether, and unsaturated carboxylic acid monomer in an amount which is 10 to 25 percent of the total mass of the chloroethylene and the isobutyl vinyl ether are used as raw materials; and the water-based chloroethylene / isobutyl vinyl ether copolymer dispersion is obtained by polymerization reaction, neutralization reaction, aqueous phase dispersion treatment and organic solution removal in organic solvent, initiator and organic amine neutralizer. The dispersion has low volatile organic compound (VOC) content, environmental friendliness and good cohesiveness, and is particularly suitable for producing water-based coating, water-based adhesive and water-based ink.

Owner:JIANGSU LISIDE NEW MATERIAL

Polyurethane-urea modified self-emulsifying nanometer waterborne epoxy emulsion and preparation method thereof

ActiveCN102295735BHas self-emulsifying propertiesAccelerated corrosionPolyurea/polyurethane coatingsEpoxyHigh pressure

The invention relates to polyurethane-urea modified self-emulsifying nanometer waterborne epoxy emulsion and a preparation method thereof. The emulsion has solid content of 40-50%, an average particle size of less than 500nm and a viscosity of 500-650(mPa*S). A chain segment in the self-emulsifying nanometer waterborne emulsion of the invention is introduced with a compound containing a nonionic hydrophilic chain segment, so that epoxy resin can have a self-emulsifying property, and the corrosion resistance and curing time of a coating can be improved by the polyurethane-urea based chain segment.A water dispersion system formed by the modified epoxy resin is then subjected to high pressure emulsification by a homogenizer and the particle size is dispersed to a nanoscale, and after a long time storage, physicochemical properties change little. Thus, the emulsion of the invention has good stability. The synthesis process of the method provided in the invention adds no organic solvent and has simple operation, thus being easy to realize.

Owner:TIANJIN UNIV

Preparation method for polysiloxanes-amidopolyether block copolymer

InactiveCN102199295BBroad encapsulationWide penetration abilityFibre treatmentPolyelectrolytePolymer science

The invention discloses a preparation method for a polysiloxanes-amidopolyether block copolymer, comprising the steps of preparation of an intermediate of alpha, omega-hydrosiloxane, preparation of an intermediate of alpha, omega-polysiloxanes diepoxide, and preparation of the polysiloxanes-amidopolyether block copolymer. The polysiloxanes-amidopolyether block copolymer provided in the invention enables a textile finishing agent to be stable under condition of high temperature, a polyelectrolyte, a high pH value or a high shear force without breaking emulsion, sticking to a roller or a cylinder and producing oil marks, allows textiles finished to be returned for repairing, and is widely used in fields like chemical fiber, natural fiber and blended products thereof, etc.

Owner:HANGZHOU MEIGAO HUAYI CHEM

Polyurea-modified self-emulsifying nano aqueous epoxy emulsion and preparation method thereof

Owner:TIANJIN UNIV

Preparation method of anionic organic-solvent-free and emulsifier-free polyurethane microemulsion

InactiveCN102977282BHas self-emulsifying propertiesHigh solid contentCoatingsGraft polymer adhesivesPolymer scienceAdhesive

The invention discloses a preparation method of an anionic organic-solvent-free and emulsifier-free polyurethane microemulsion. The preparation method comprises the following steps of: carrying out polymerization of isocyanate and polymer polyol by replacing an organic cosolvent used in the preparation process of the traditional polyurethane-polyacrylate microemulsion with inertial vinyl monomers to prepare a polyurethane prepolymer of which the terminal group is provided with unsaturated bonds, carrying out cooling, neutralization and aqueous dispersion on the polyurethane prepolymer, and then further initiating the polymerization of the vinyl monomers under the action of a water-soluble initiator to prepare the anionic organic-solvent-free and emulsifier-free polyurethane microemulsion. The preparation method disclosed by the invention thoroughly gets rid of the organic cosolvent added in the traditional waterborne polyurethane and achieves a real sense of environmental friendliness; and in addition, no emulsifier is added in the preparation process, and the prepared anionic organic-solvent-free and emulsifier-free polyurethane microemulsion has nano-scale particle diameter, is excellent in performance and can be used for a waterborne coating and the field of adhesives due to formula adjustment.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of manufacture method of non-yellowing fluffing agent

ActiveCN103726338BHas self-emulsifying propertiesHigh temperature resistantFibre treatmentChemical industryChemical structure

The invention relates to a preparation method of a non-yellowing fluffing agent, belonging to the organic synthesis and high-molecular polymerization reactions in the fields of chemical industry and high polymer chemistry. The method is characterized by comprising the following steps: preparing methyl-terminated polyether modified silicone oil for the non-yellowing fluffing agent, emulsifying to obtain a methyl-terminated polyether modified silicone oil emulsion, and compounding with fatty acid amide compounds, glacial acetic acid and deionized water to obtain the non-yellowing fluffing agent. By adopting the technical scheme, the method provided by the invention has the advantages and positive effects that in the prepared methyl-terminated polyether modified silicone oil with a novel structure, a hydrophilic polyether group is introduced to the chemical structure, thus the methyl-terminated polyether modified silicone oil has self-emulsifying property and is very convenient to emulsify; the prepared silicone oil emulsion has stable properties such as high-temperature resistance, acid-base resistance and no demulsification; meanwhile, by adopting methyl to terminate silicone oil, the existence of primary amine on the silicone oil chain is replaced, and the defects such as yellow spots of the silicone oil emulsion on the fabric are avoided.

Owner:SHEYANG TIANYUAN CHEM IND CO LTD

Method for synthesizing cellulose nitrate-polyurethane-polyacrylic acid(polyacrylate) composite emulsion

InactiveCN101235125BHas self-emulsifying propertiesGood drying propertiesEmulsion paintsCellulosePolymer science

The invention discloses a preparation method of cellulose nitrate-polyurethane-polyacrylic acid (ester) composite emulsion, which comprises using toluene diisocyanate, dealcoholized cellulose nitrate, polyether polyol, butanediol, dimethylol propionic acid and triethylamine as main raw materials, using step addition polymerization to synthesize anion polyurethane-cellulose nitrate water disperser, using the water disperser as seed emulsion, without any surface activator, via adding inducer to process in-site emulsion polymerization with polymer emulsion and emulsified acroleic acid monomer, to process polymerization and / or crosslink of pre-emulsified acroleic acid(ester) monomer in the seed emulsion seed and at surface, thereby preparing aqueous cellulose nitrate-polyurethane-polyacrylic acid (ester) composite latex particle with core-shell structure or interpenetrating polymer which can be used as filming polymer of high-performance aqueous wood dye.

Owner:SOUTH CHINA UNIV OF TECH

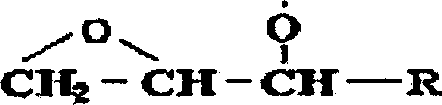

A kind of waterproof fatliquoring agent and preparation method thereof

ActiveCN108265135BHas self-emulsifying propertiesImprove bindingLeather impregnationPhosphoric Acid EstersCompound a

The invention discloses a waterproof fatliquoring agent and a preparation method for the waterproof fatliquoring agent. The preparation method for the waterproof fatliquoring agent comprises the stepsthat (1), compound A and compound B are mixed according to the weight ratio of 1 : (0.1-0.25), the compound A and the compound B are both long carbon chain compound containing primary amine group, then carboxylation modification reagent with the total amount of substance being 0.8-1.2 times that of the primary amine group is added in the mixture, stirring reaction is performed, and long carbon chain amine carboxyl compound is obtained; (2), 45-65 parts of the long carbon chain amine carboxyl compound prepared in the step (1), 8-15 parts of alkanolamide phosphate, 10-15 parts of maleic anhydride grafting hydrocarbon polymer and 2-6 parts of compatilizer are mixed and stirred evenly, then alkali metal solution is dropped and added to adjust the pH to be 7.5-8.5, and then water is added to adjust the solid content to be 35-55%. The waterproof fatliquoring agent has better waterproof performance and good room temperature flowing performance.

Owner:四川亭江新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com