Polyurea-modified self-emulsifying nano aqueous epoxy emulsion and preparation method thereof

A water-based epoxy emulsion, self-emulsification technology, applied in the chemical industry, can solve the problem that the sexual system is still in its infancy, Nanjing University, organic solvents are not conducive to environmental protection, etc., and achieve the effect of easy implementation, good stability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Synthesis of modified epoxy resin: first add 13.6g of epoxy resin E-44 to a 250mI four-neck flask equipped with a stirrer, electric heating mantle, condenser tube and thermometer, raise the temperature to 50°C, and slowly add 23.1g of D2000 dropwise The mixture with diethanolamine is heated to 80°C and reacted for 4 hours to obtain a modified epoxy resin.

[0023] 2. Synthesis of prepolymer: the above reaction system was cooled to 50°C, 1.7g of TDI was slowly added dropwise, and reacted for 1 hour to obtain an epoxy prepolymer.

[0024] 3. Mix 4g of the epoxy resin prepolymer obtained above with 40g of E-44, react at 60°C for 1 hour, and take it out from the reaction vessel.

[0025] 4. The above product was dispersed at a high speed of 1000r / min, and 110g of distilled water was added dropwise to obtain a polyurea-modified epoxy resin emulsion.

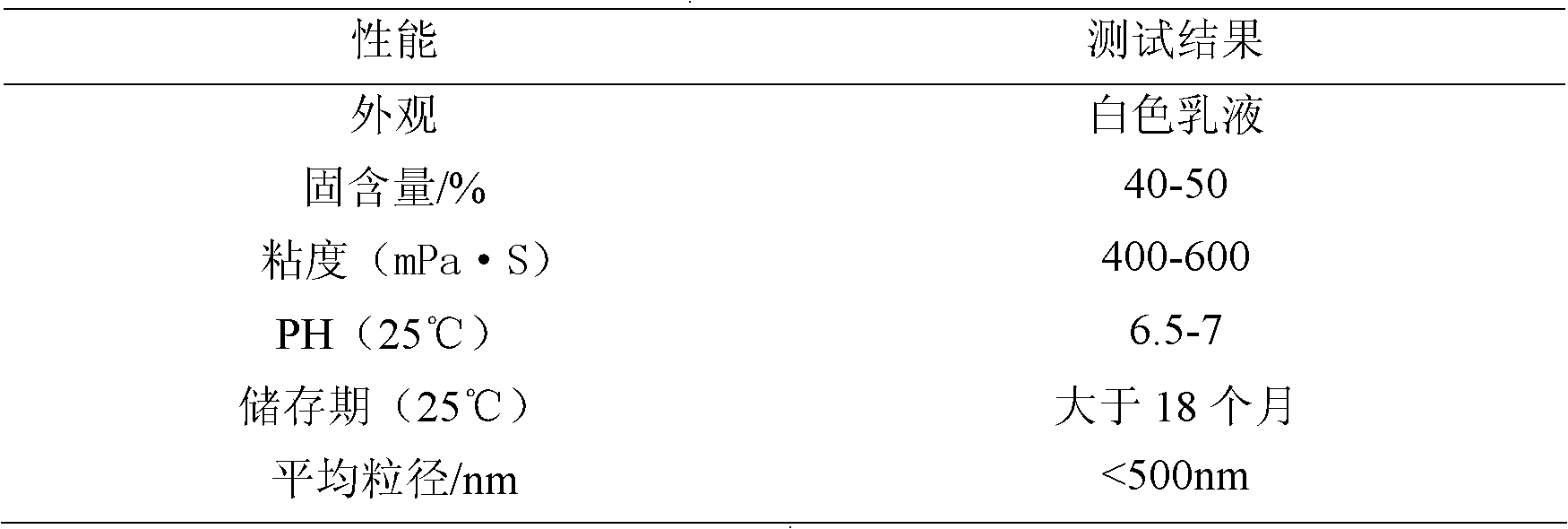

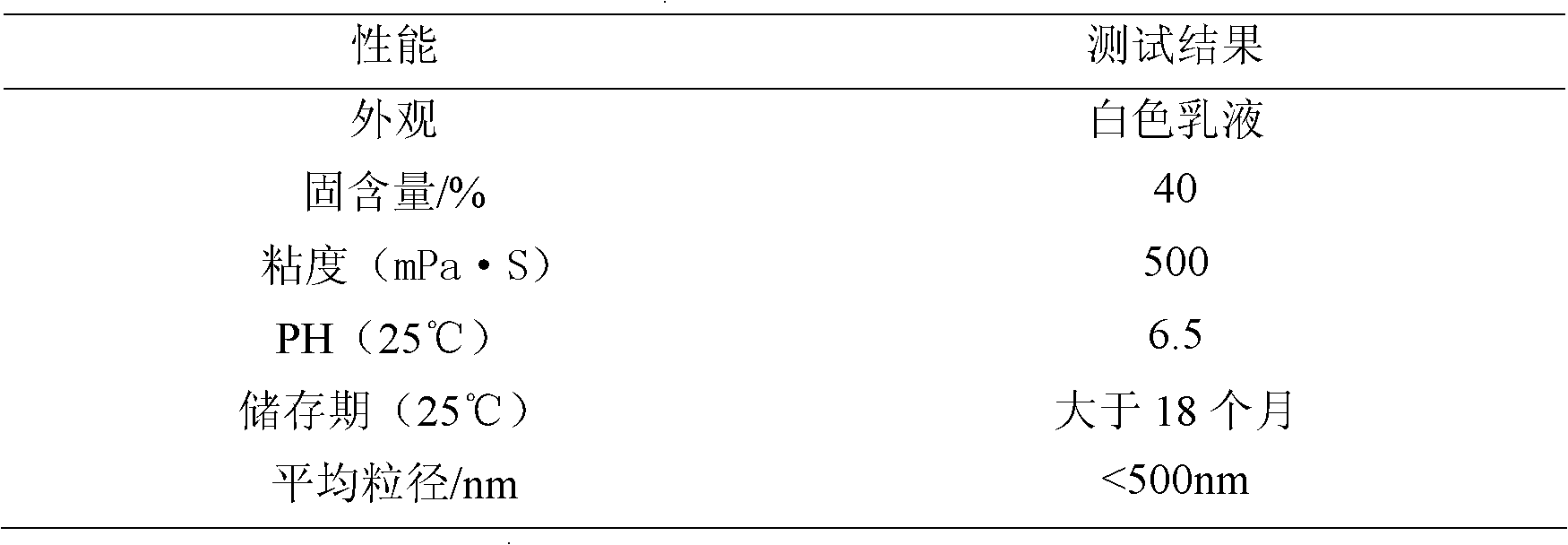

[0026] 5. Disperse the above emulsion for 30 minutes under the condition of a vertical colloid mill at 2500 r / min, and th...

Embodiment 2

[0029] 1. Synthesis of modified epoxy resin: first add 4.5g of epoxy resin E-44 to a 250mI four-neck flask equipped with a stirrer, electric heating mantle, condenser tube and thermometer, raise the temperature to 60°C, and slowly add 23.1g of D2000 dropwise The mixture with diethanolamine is heated to 100°C and reacted for 6 hours to obtain a modified epoxy resin.

[0030] 2. Synthesis of prepolymer: the above reaction system was cooled to 70°C, 2.6g of MDI was slowly added dropwise, and reacted for 2 hours to obtain an epoxy prepolymer.

[0031] 3. Mix 4g of the epoxy resin prepolymer obtained above with 20g of E-44, react at 90°C for 3h, and take it out from the reaction vessel.

[0032] 4. The above product was dispersed at a high speed of 1000r / min, and 48g of distilled water was added dropwise to obtain a polyurea-modified epoxy resin emulsion.

[0033] 5. Disperse the above emulsion for 1.5 hours in a vertical colloid mill at 3500r / min, and then use a nano homogenizer ...

Embodiment 3

[0036] 1. Synthesis of modified epoxy resin: First add 13.6g of epoxy resin E-44 to a 250mI four-neck flask equipped with a stirrer, electric heating mantle, condenser tube and thermometer, raise the temperature to 55°C, and slowly add 23.1g dropwise The mixture of D2000 and diethanolamine was heated up to 90°C and reacted for 5 hours to obtain a modified epoxy resin.

[0037] 2. Synthesis of prepolymer: the temperature of the above reaction system was lowered to 60°C, 1.7g HDI was slowly added dropwise, and the epoxy prepolymer was obtained by reacting for 1.5h.

[0038] 3. Mix 4g of the epoxy resin prepolymer obtained above with 40g of E-44, react at 70°C for 2h, and take it out from the reaction vessel.

[0039] 4. The above product was dispersed at a high speed of 1000r / min, and 88g of distilled water was added dropwise to obtain a polyurea-modified epoxy resin emulsion.

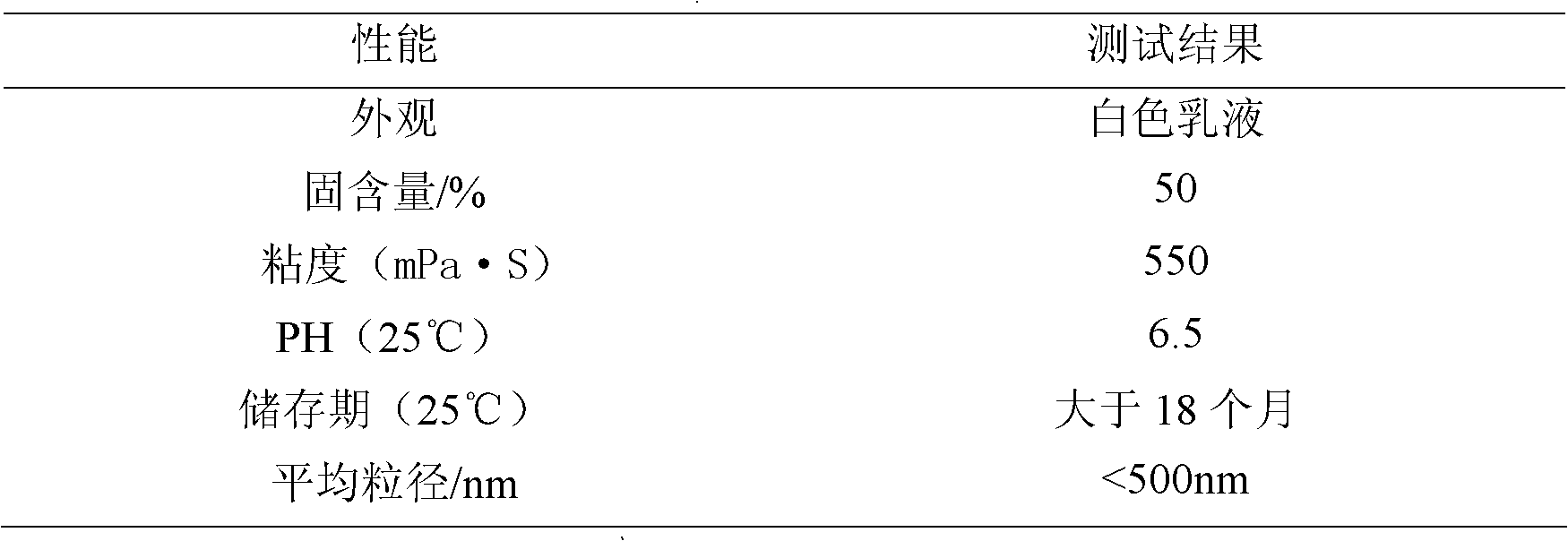

[0040] 5. Put the above emulsion through a vertical colloid mill at 2500r / min, disperse for 1h, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com