Method for synthesizing cellulose nitrate-polyurethane-polyacrylic acid(polyacrylate) composite emulsion

A technology of nitrocellulose and polyacrylate, which is applied in the direction of latex paint, etc., can solve the problems of single water-based nitrocellulose emulsion products, poor water resistance, and many homogeneous products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

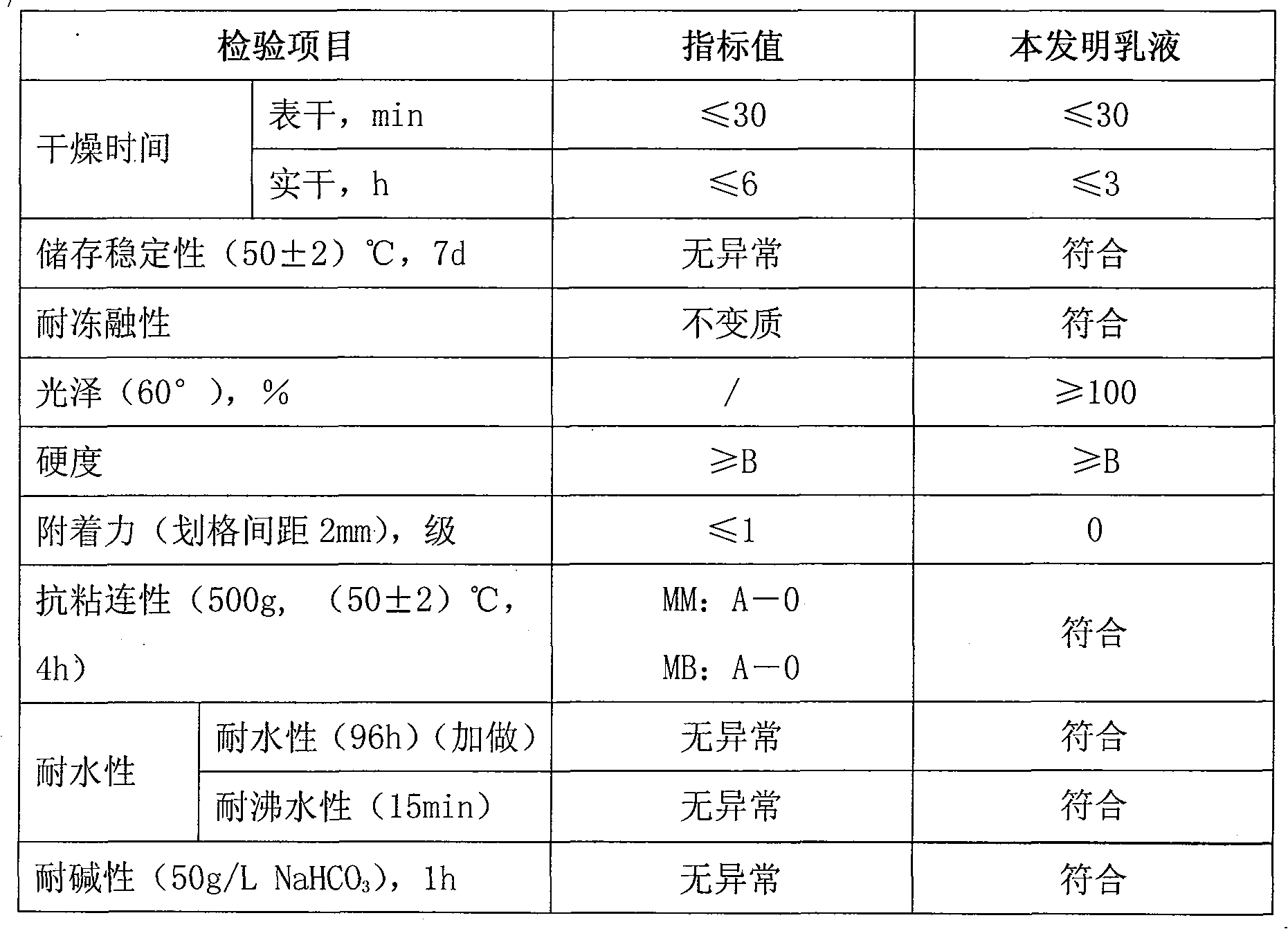

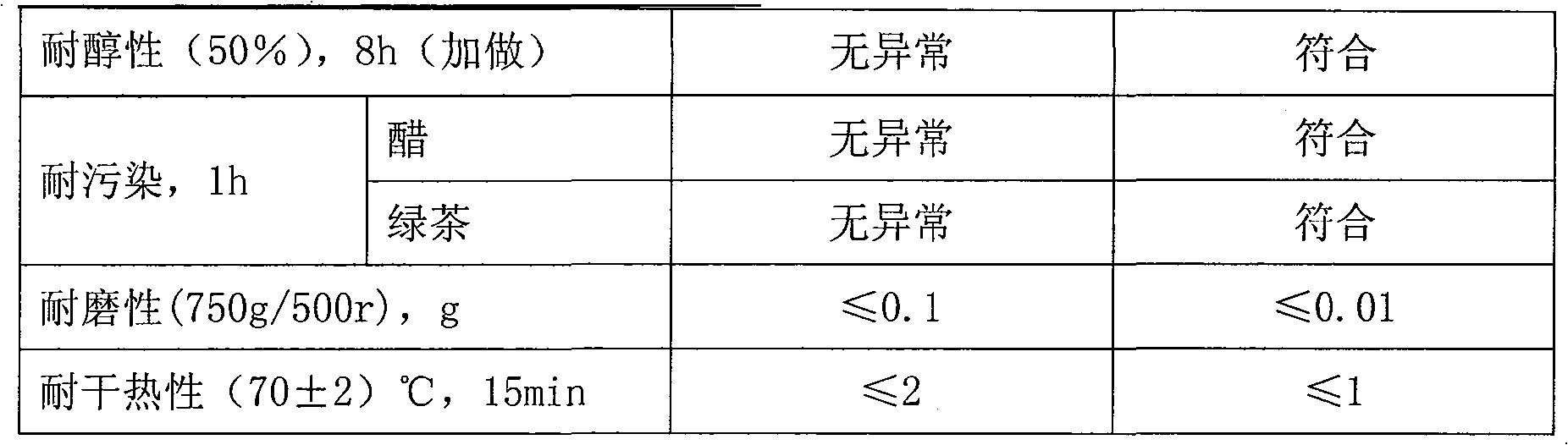

Examples

Embodiment 1

[0034] The raw materials and consumption of synthetic water-based nitrocellulose-polyurethane-polyacrylate composite emulsion are as follows:

[0035] Toluene diisocyanate (TDI) 39.2 kg

[0036] Polyoxypropylene glycol (PPG) 50.2 kg

[0037] 1,4-butanediol (BDO) 6.3 kg

[0038] Dimethylolpropionic acid (TMPA) 6.2 kg

[0039] Nitrocellulose (70%, acetone solvent) 121.1 kg

[0040] Triethylamine (TEA) 4.1 kg

[0041] Methyl methacrylate (MMA) 14.0 kg

[0042] Butyl acrylate (BA) 7.0 kg

[0043] Acrylic acid (AA) 0.2 kg

[0044] Azobisisobutyronitrile (AIBN) 0.2 kg

[0045] Acetone 20.9 kg

[0046] Isooctyl acetate 7.0kg

[0047] Water 337.6 kg

[0048] Total 642.4 kg

[0049] The synthesis steps are:

[0050] (1) Preparation of prepolymer: according to the above formula, 39.2 kg of TDI and 50.2 kg of dehydrated polyether glycol PPG are added to a 1000L reactor, and the material is stirred at a speed of 300 rpm and gradually Raise the temperature to 65°C, keep the re...

Embodiment 2

[0056] The raw materials and consumption of synthetic water-based nitrocellulose-polyurethane-polyacrylate composite emulsion are as follows:

[0057] Toluene diisocyanate (TDI) 53.0 kg

[0058] Polyoxypropylene glycol (PPG) 66.1 kg

[0059] 1,4-butanediol (BDO) 9.8 kg

[0060] Dimethylolpropionic acid (TMPA) 7.3 kg

[0061] Nitrocellulose (70%, acetone solvent) 38.0 kg

[0062] Triethylamine (TEA) 5.5 kg

[0063] Methyl methacrylate (MMA) 60.0 kg

[0064] Butyl acrylate (BA) 30.0 kg

[0065] Acrylic acid (AA) 4.5 kg

[0066] Azobisisobutyronitrile (AIBN) 0.5 kg

[0067] Acetone 89.2 kg

[0068] Isooctyl acetate 12.0 kg

[0069] Water 375.4 kg

[0070] Total 751.3 kg

[0071] The synthesis steps are:

[0072] (1) Preparation of prepolymer: according to the above formula, 53.0 kg of TDI and 66.1 kg of dehydrated polyether glycol PPG are added to a 1000L reactor, and the material is stirred at a speed of 30 rpm and gradually Raise the temperature to 60°C, keep the r...

Embodiment 3

[0078] The raw materials and consumption of synthetic water-based nitrocellulose-polyurethane-polyacrylate composite emulsion are as follows:

[0079] Toluene diisocyanate (TDI) 24.5 kg

[0080] Polyoxypropylene glycol (PPG) 30.6 kg

[0081] 1,4-butanediol (BDO) 3.2 kg

[0082] Dimethylolpropionic acid (TMPA) 11.1 kg

[0083] Nitrocellulose (70%, acetone solvent) 150.0 kg

[0084] Triethylamine (TEA) 7.3 kg

[0085] Methyl methacrylate (MMA) 90.0 kg

[0086] Butyl acrylate (BA) 30.0 kg

[0087] Acrylic acid (AA) 3.0 kg

[0088] Azobisisobutyronitrile (AIBN) 0.5 kg

[0089] Acetone 25.0 kg

[0090] Isooctyl acetate 4.0kg

[0091] Water 396.0 kg

[0092] Total 775.2 kg

[0093] The synthesis steps are:

[0094] (1) Preparation of prepolymer: According to the above formula, 24.5 kg of TDI and 30.6 kg of dehydrated polyether glycol PPG are added to a 1000L reactor, and the material is stirred at a speed of 100 rpm and gradually Raise the temperature to 65°C, keep the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com