Polyurethane-urea modified self-emulsifying nano water-based epoxy emulsion and preparation method thereof

A water-based epoxy emulsion, self-emulsifying technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of long modification curing time, unfavorable spraying construction, etc., to improve curing time, improve corrosion resistance, improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

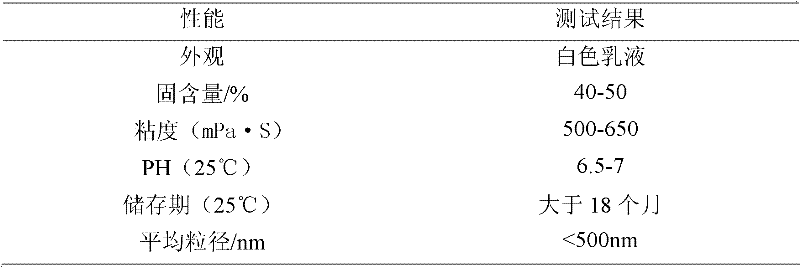

Embodiment 1

[0023] 1. Synthesis of modified epoxy resin: first add 13.6g of epoxy resin E-44 to a 250mI four-neck flask equipped with a stirrer, electric heating mantle, condenser tube and thermometer, raise the temperature to 50°C, and slowly add 23.1g of D2000 dropwise The mixture with PEG1000 is heated to 80°C and reacted for 4 hours to obtain a modified epoxy resin.

[0024] 2. Synthesis of prepolymer: the above reaction system was cooled to 50°C, 1.7g of TDI was slowly added dropwise, and reacted for 1 hour to obtain an epoxy prepolymer.

[0025] 3. Mix 4g of the epoxy resin prepolymer obtained above with 40g of E-44, react at 60°C for 1 hour, and take it out from the reaction vessel.

[0026] 4. The above product was dispersed at a high speed of 1000r / min, and 110g of distilled water was added dropwise to obtain a polyurea-modified epoxy resin emulsion.

[0027] 5. Disperse the above emulsion for 30 minutes through a vertical colloid mill at 2500 r / min, and then use a nano homogeni...

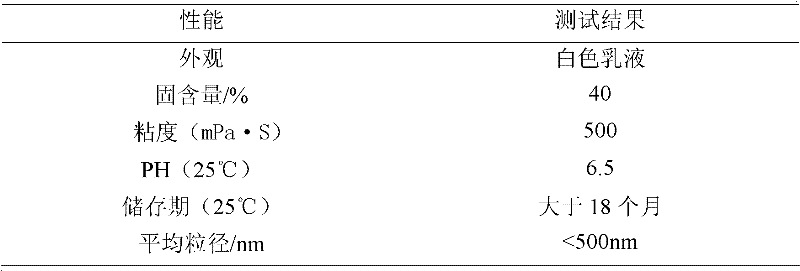

Embodiment 2

[0030] 1. Synthesis of modified epoxy resin: first add 4.5g of epoxy resin E-44 to a 250mI four-neck flask equipped with a stirrer, electric heating mantle, condenser tube and thermometer, raise the temperature to 60°C, and slowly add 23.1g of D2000 dropwise The mixture with PEG4000 is heated to 100°C and reacted for 6 hours to obtain a modified epoxy resin.

[0031] 2. Synthesis of prepolymer: the above reaction system was cooled to 70°C, 2.6g of MDI was slowly added dropwise, and reacted for 2 hours to obtain an epoxy prepolymer.

[0032] 3. Mix 4g of the epoxy resin prepolymer obtained above with 20g of E-44, react at 90°C for 3h, and take it out from the reaction vessel.

[0033] 4. The above product was dispersed at a high speed of 1000r / min, and 48g of distilled water was added dropwise to obtain a polyurea-modified epoxy resin emulsion.

[0034] 5. Disperse the above emulsion for 1.5 hours in a vertical colloid mill at 3500r / min, and then use a nano homogenizer to emul...

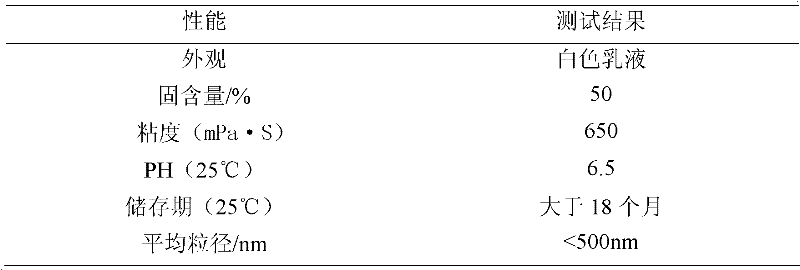

Embodiment 3

[0037] 1. Synthesis of modified epoxy resin: First add 13.6g of epoxy resin E-44 to a 250mI four-neck flask equipped with a stirrer, electric heating mantle, condenser tube and thermometer, raise the temperature to 55°C, and slowly add 23.1g dropwise The mixture of D2000 and PEG4000 was heated to 90°C and reacted for 5 hours to obtain a modified epoxy resin.

[0038] 2. Synthesis of prepolymer: the temperature of the above reaction system was lowered to 60°C, 1.7g HDI was slowly added dropwise, and the epoxy prepolymer was obtained by reacting for 1.5h.

[0039] 3. Mix 4g of the epoxy resin prepolymer obtained above with 40g of E-44, react at 70°C for 2h, and take it out from the reaction vessel.

[0040] 4. The above product was dispersed at a high speed of 1000r / min, and 88g of distilled water was added dropwise to obtain a polyurea-modified epoxy resin emulsion.

[0041] 5. Put the above emulsion through a vertical colloid mill at 2500r / min, disperse for 1h, and then use a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com