Electrostatic painting anticorrosive oil and production method thereof

An electrostatic spraying, anti-rust oil technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve problems such as scratches on steel plates, poor lubricating performance of anti-rust oil, affecting the surface quality of steel plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

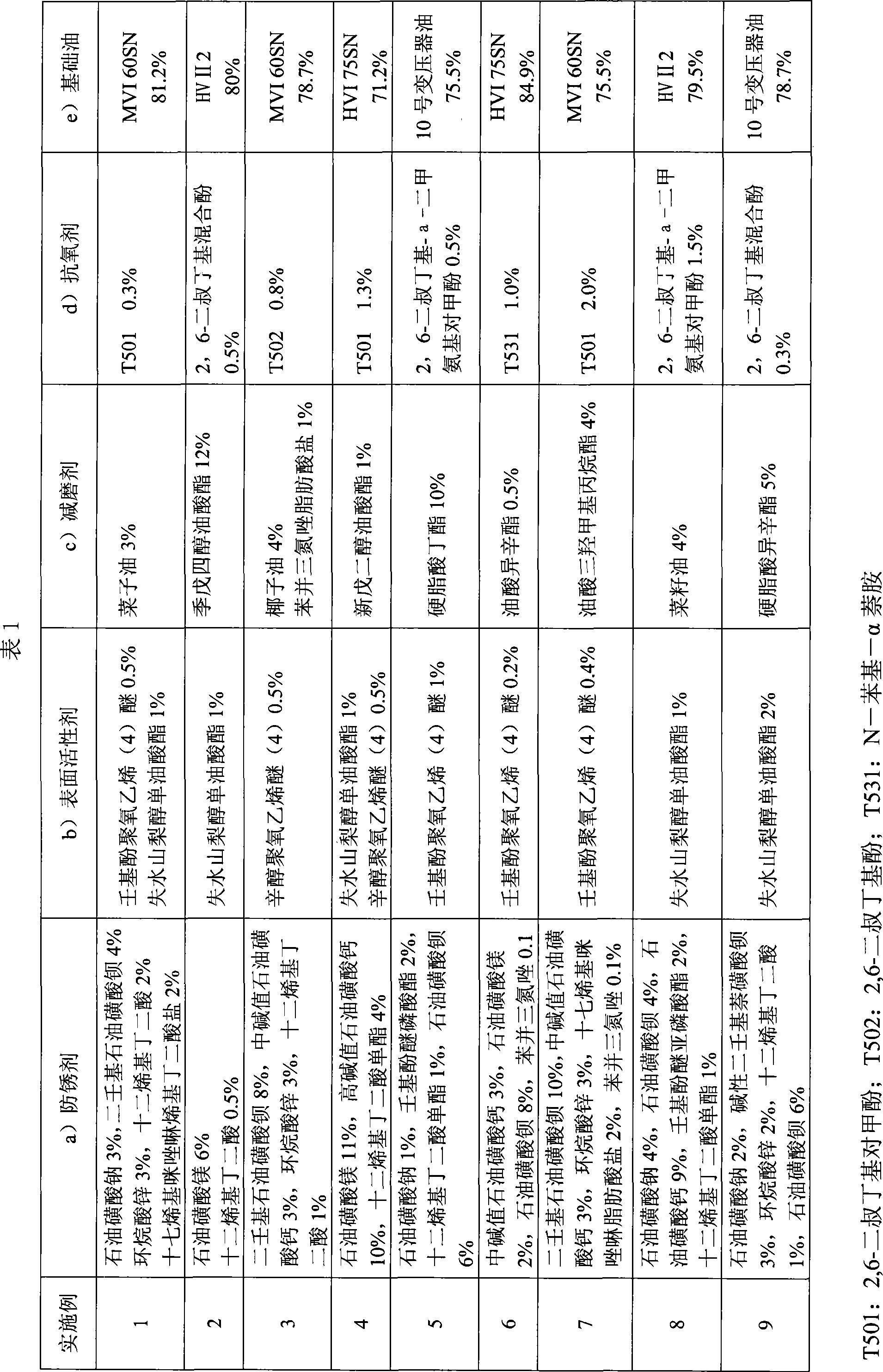

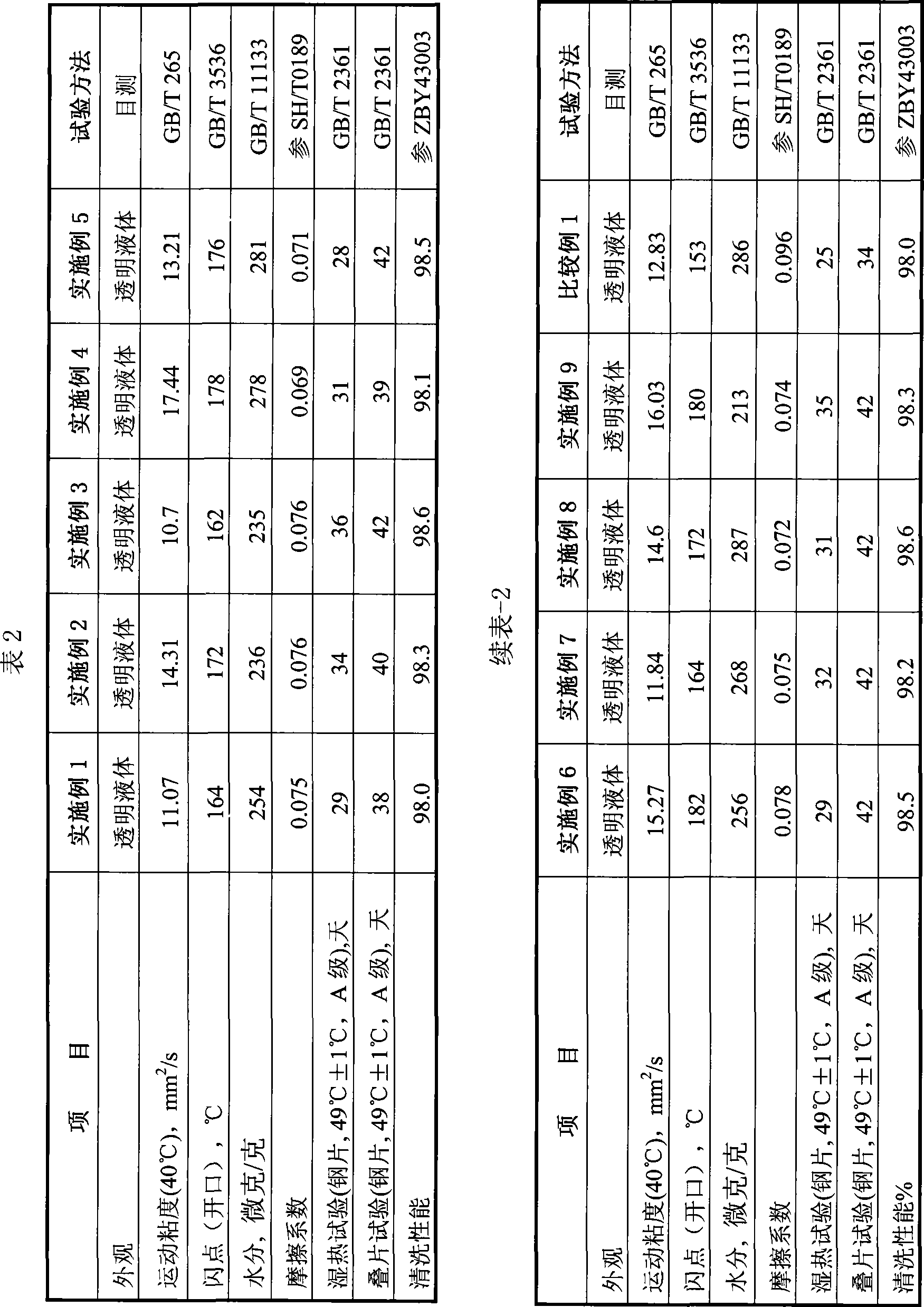

[0025] Mix the required amount of base oil, anti-rust agent, surfactant, anti-friction agent and antioxidant, heat to 115°C, stir at constant temperature for 5 minutes, cool down to 75°C, filter and pack after passing the inspection. Wherein each component and its weight percentage are shown in Table 1, and product performance is shown in Table 2.

[0026] In Table 1, c) component friction reducing agent, wherein butyl stearate is synthesized by stearic acid and butanol, neopentyl glycol oleate is synthesized by neopentyl glycol and oleic acid, and pentaerythritol oleate It is synthesized from pentaerythritol and oleic acid. Isooctyl oleate is synthesized from oleic acid and isooctyl alcohol. Trimethylolpropane oleate is synthesized from oleic acid and trimethylolpropane. Octyl esters are synthesized from stearic acid and isooctyl alcohol. Its synthesis process adopts the conditions disclosed in "Fine Organic Chemical Preparation Handbook, Scientific and Technical Literature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com