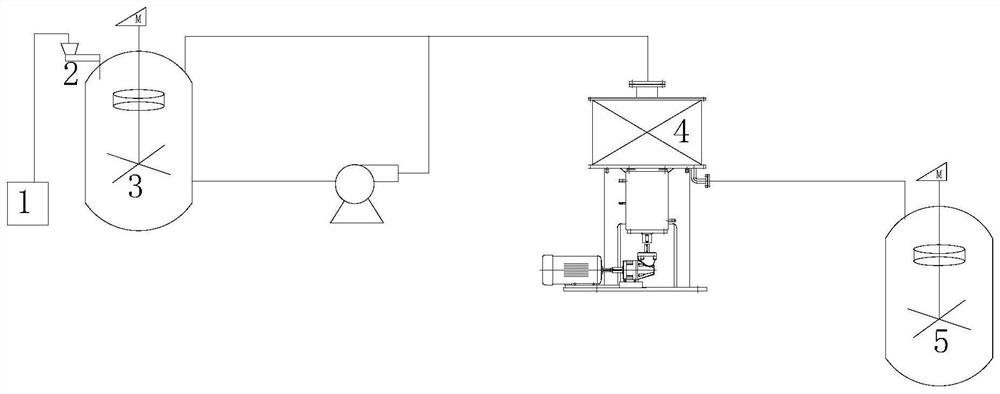

System and process for continuously producing diazonium salt solution

A diazonium salt and solution technology, applied in chemical instruments and methods, dissolution, organic chemistry, etc., can solve the problems of adaptability improvement of hypergravity reactors, large area of reactors, and few diazonium components, etc. Achieve the effect of enhancing mass transfer effect and residence time, reducing dead angle deposition, mixing and fully reacting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

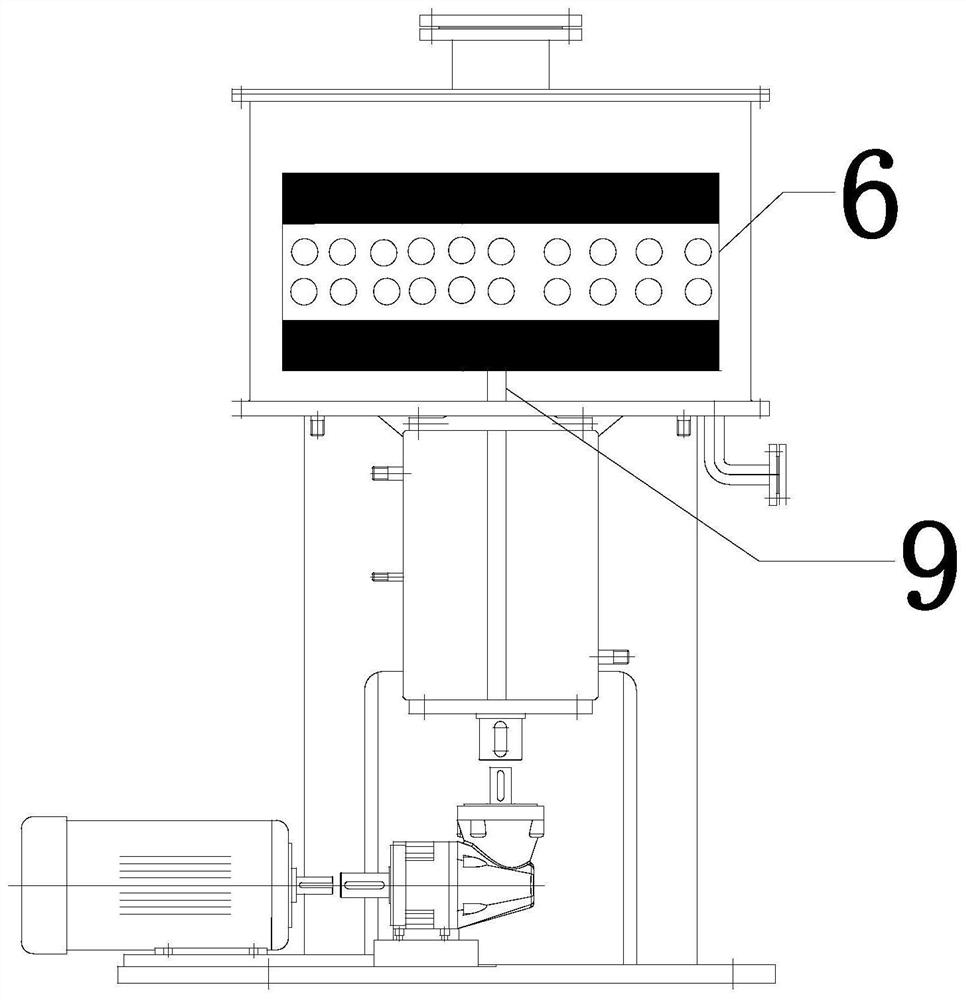

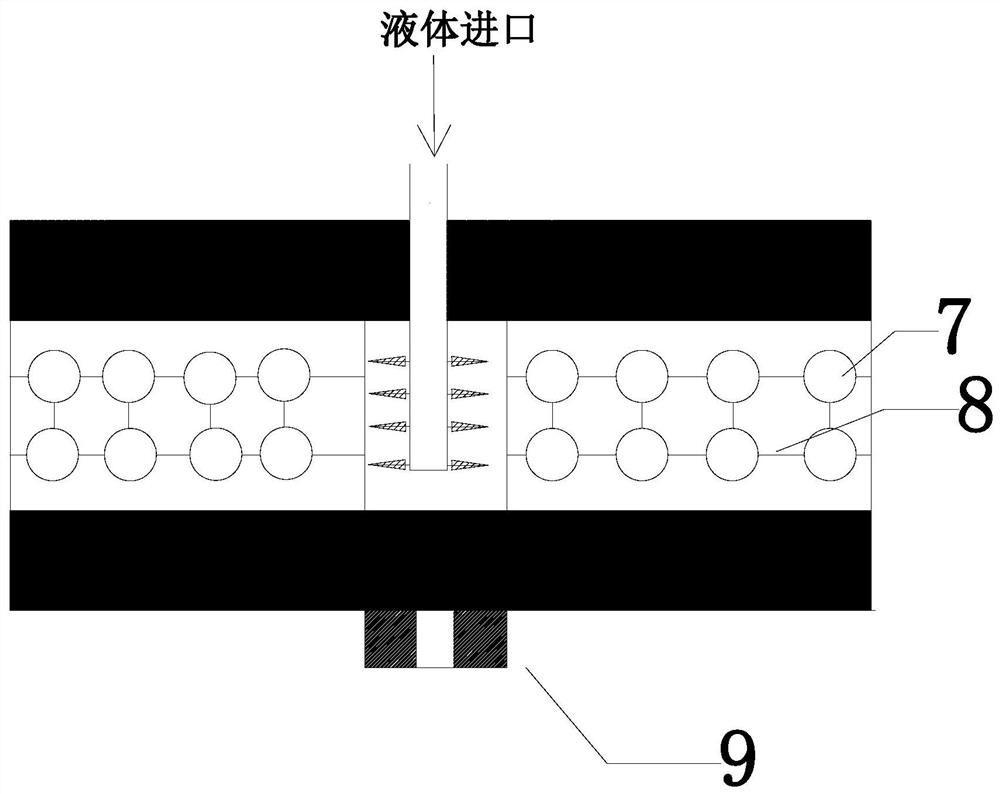

Embodiment 1

[0052] A 1-square pre-mixing tank is used to connect the diazotization reactors in series, the finished product is a 1-square tank, and the stirring speed of the pre-mixing tank is controlled at 300r / min. First, add 300L 28wt% nitrosylsulfuric acid solution (referred to as liquid sub) into the pre-mixing tank, then transport p-nitroaniline to the weighing screw feeder through the pipe chain conveying equipment, and put in p-nitrosylsulfuric acid through the feeder 158kg of aniline, mixed reaction for 30-40 minutes, the temperature of the pre-mixing kettle is controlled at 15-20°C through the jacket and the coil. Subsequently, 150kg / h and 510kg / h of p-nitroaniline and liquid nitrate were respectively fed into the premix tank at the same time, and the temperature of the premix tank was controlled at 15-20°C through a jacket and a coil. The pre-mixed tank is discharged, and fed to the diazotization reactor at a flow rate of 660kg / h through the pump for further diazotization react...

Embodiment 2

[0054] A 1-square pre-mixing tank is used to connect the diazotization reactors in series, the finished product is a 1-square tank, and the stirring speed of the pre-mixing tank is controlled at 400r / min. First, add 300L 28wt% nitrosyl sulfuric acid solution (abbreviated as liquid sub) in the premix tank, then transport 2,4-dinitro-6-chloroaniline to the weighing screw feeder through the screw conveyor, Put 250kg of 2,4-dinitro-6-chloroaniline into the feeder, react for 30 minutes, and control the temperature of the premixing tank at 18-23°C. Subsequently, 2,4-dinitro-6-chloroaniline and liquid sub-alternatives were simultaneously fed into the premix tank at 200kg / h and 420kg / h respectively. The pre-mixed tank is discharged, and fed to the diazotization reactor at a flow rate of 620kg / h through the pump for further diazotization reaction. The speed of the diazotization reactor is 1500rpm, and the diameter of the channel is 0.5mm, spherical The diameter of the cavity is 4mm, t...

Embodiment 3

[0056] A 1-square pre-mixing tank is used to connect the diazotization reactors in series, the finished product is a 1-square tank, and the stirring speed of the pre-mixing tank is controlled at 400r / min. First, add 300L 28wt% nitrosyl sulfuric acid solution (abbreviated as liquid sub) in the premix tank, then transport 2,6-dichloro-4-nitroaniline to the weighing screw feeder through the screw conveyor, Put 250kg of 2,6-dichloro-4-nitroaniline into the feeder, react for 40-50 minutes, and control the temperature of the pre-mixing tank at 20-23°C. Subsequently, 2,6-dichloro-4-nitroaniline and liquid sub-alcohol were simultaneously fed into the premix tank at 200kg / h and 420kg / h respectively. The pre-mixed tank is discharged, and fed to the diazotization reactor at a flow rate of 620kg / h through the pump for further diazotization reaction. The speed of the diazotization reactor is 1800rpm, and the diameter of the channel is 0.5mm, spherical The diameter of the chamber is 4mm, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com