KR desulfurization method and desulfurization equipment thereof

A technology of desulfurization equipment and desulfurizer, which is applied in the field of metallurgy, can solve problems such as desulfurizer agglomeration, and achieve the effects of alleviating agglomeration, improving utilization rate, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

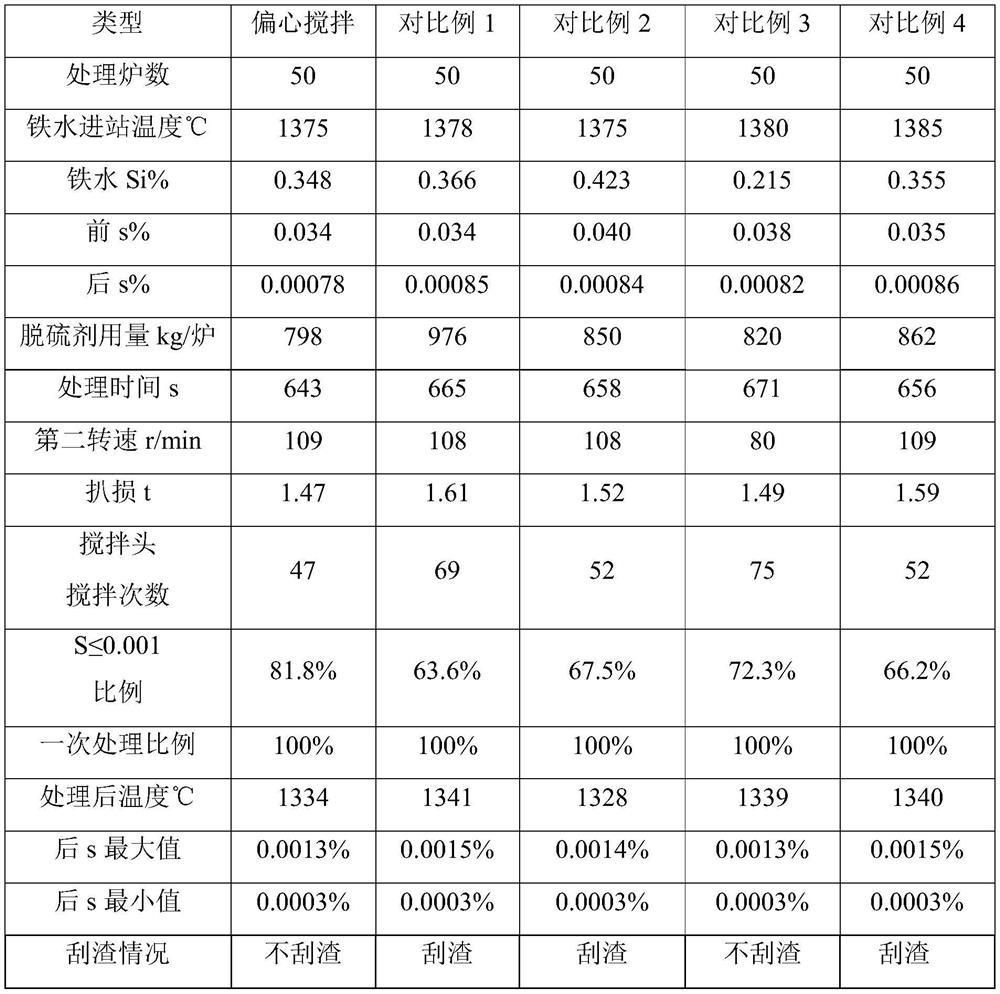

Examples

Embodiment 1

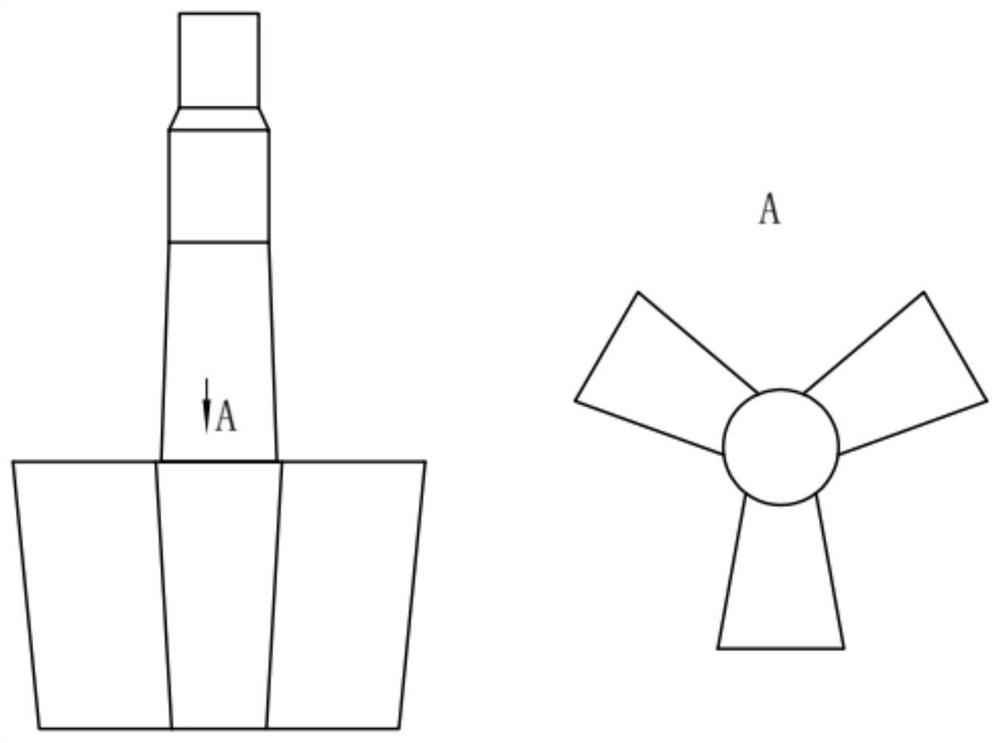

[0057] see figure 2 , figure 2 It is a schematic diagram of the structure of the three-blade mixing head, and A is the view viewed from the direction of A; taking the KR desulfurization production site of Lianyuan Steel Refining Group Co., Ltd. as an example, the iron ladle used in its production has a cylindrical upper part and an elliptical lower part The bottom of the tank, the inner diameter of the tank bottom is 2.2-2.5m, and the height is 4.0-4.2m; the stirring head used is a three-leaf stirring head with a radius of 0.60m. Length 500mm, bottom length 450mm;

[0058] The composition and temperature of the molten iron for KR desulfurization treatment meet the following requirements: the temperature of the molten iron is 1280-1420°C, and the molten iron contains the following components by weight percentage: C: 4.0%-4.5%, Si: 0.2%-1.5%, Mn: 0.2% to 0.5%, P: 0.08% to 0.15%, S: 0.02% to 0.1%, and Ti: 0.03% to 0.09%; for molten iron within the above composition and temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com