Tumble guide type high compression ratio piston of gasoline engine

A tumble-oriented, high-compression-ratio technology, applied in pistons, mechanical equipment, engine components, etc., can solve the problems of hindering the development of tumble flow in the cylinder, slowing down the combustion speed, and enhancing the tendency of knocking, so as to reduce the oil beam. The amount of collision, suppressing knocking, and improving the effect of turbulent kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

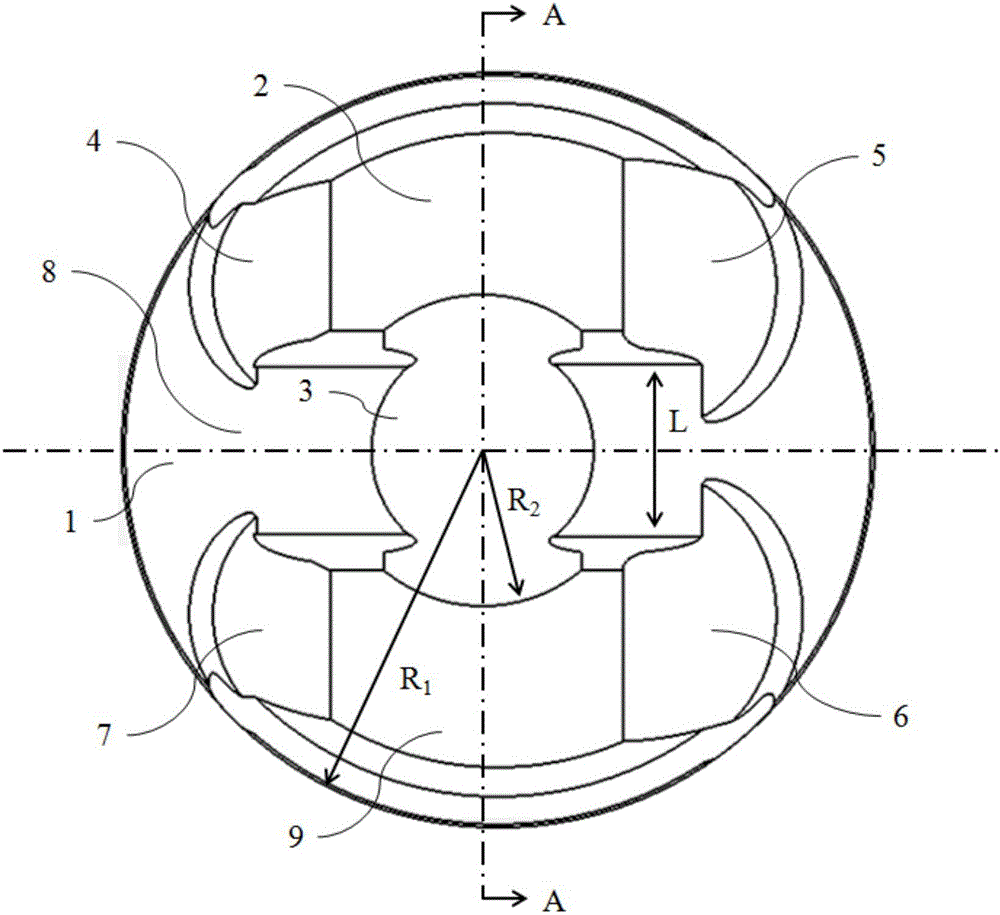

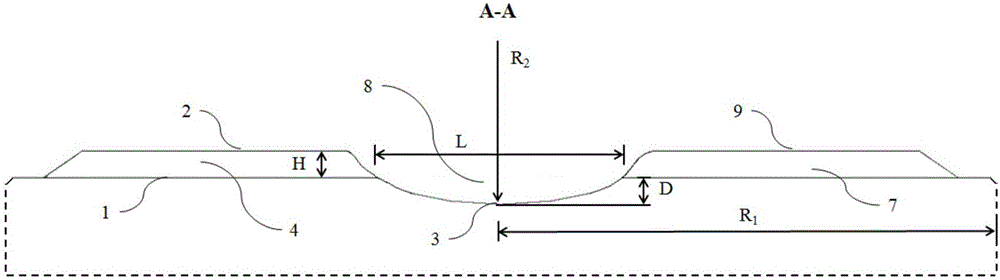

[0015] refer to figure 1 , a high-compression-ratio piston of a tumble-guided gasoline engine, characterized in that the piston includes a piston top surface 1, a first boss top surface 2, a hemispherical piston pit 3, and an extension of the first exhaust valve avoidance pit. Surface 4, the extension surface 5 of the first intake valve avoidance pit, the extension surface 6 of the second intake valve avoidance pit, the extension surface 7 of the second exhaust valve avoidance pit, the grooved tumble channel 8, the second convex Table top surface9.

[0016] The extension surface 4 of the first exhaust valve evasion pit, the extension surface 5 of the first intake valve evasion pit and the first boss top surface 2 jointly form a boss higher than the piston top surface 1; The extension surface 6 of the two intake valve evasion pits, the extension surface 7 of the second exhaust valve evasion pit and the second boss top surface 9 jointly form a boss higher than the piston top su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com