Novel trailing edge cooling structure with Y-shaped jet holes of turbine blade

A technology for turbine blades and cooling structures, applied in the direction of blade support components, engine components, machines/engines, etc., can solve the problems of complex external flow at the trailing edge of blades, inability to arrange cooling structures, and narrow cooling channels, etc., to achieve optimal Enhance heat transfer performance, avoid the reduction of jet flow, and increase the effect of heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and a series of advantages of the technical invention will be explained by comparing numerical calculation results, but the protection scope of the present invention is not limited to the following embodiments.

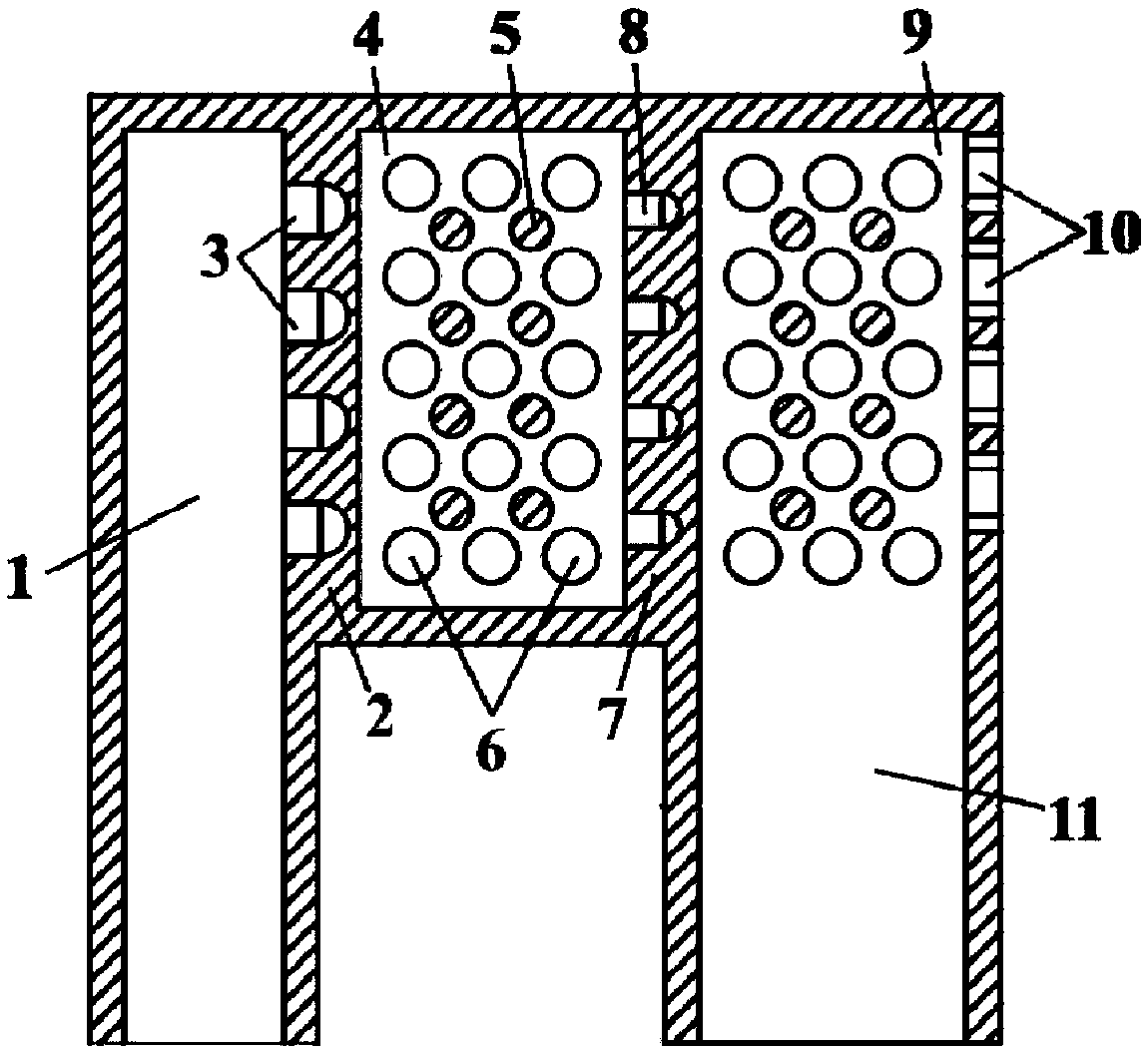

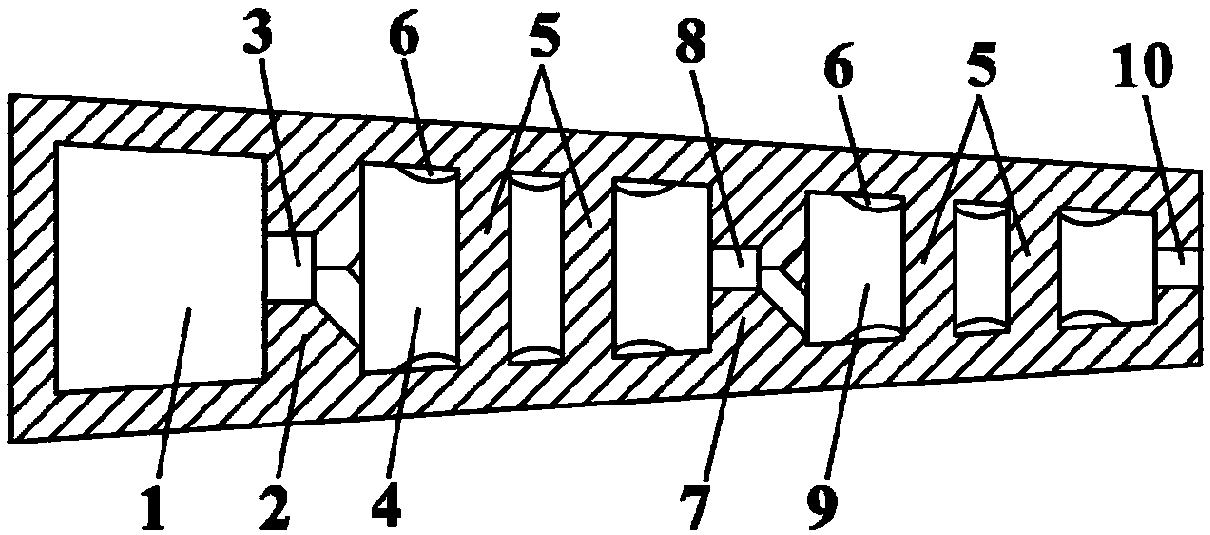

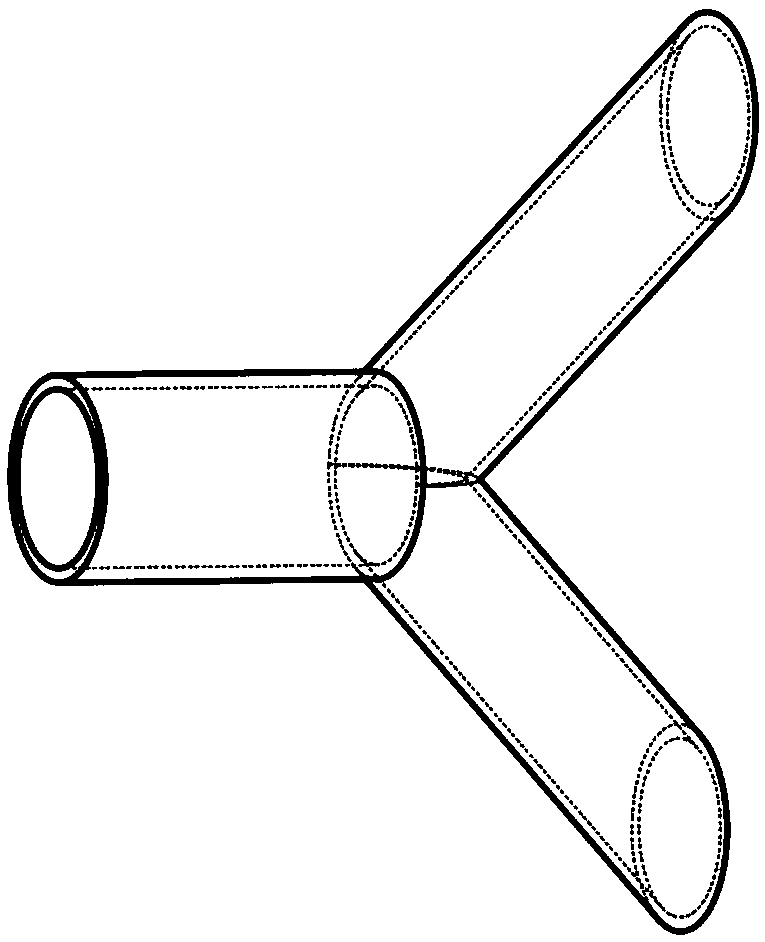

[0039] refer to Figure 1 to Figure 4, a novel turbine blade trailing edge cooling structure with a Y-shaped jet hole provided by the present invention, including a cooling medium supply chamber 1, a first partition 2, a first cooling chamber 4, a second partition 7, a Two cooling chambers 9 and an outlet section 11. The trailing edge has a trapezoidal structure as a whole, wherein the first partition 2 is between the cooling medium supply chamber 1 and the first cooling chamber 4, and the second partition 7 is between the first cooling chamber 4 and the second cooling chamber 9, The first cooling chamber 4 and the second cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com