Rapid combustor of airflow hedging natural gas engine

A technology of airflow hedging and combustion chamber, which is applied in the directions of engine components, machines/engines, mechanical equipment, etc., and can solve the problems of fast combustion chamber reports of natural gas engines without airflow hedging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

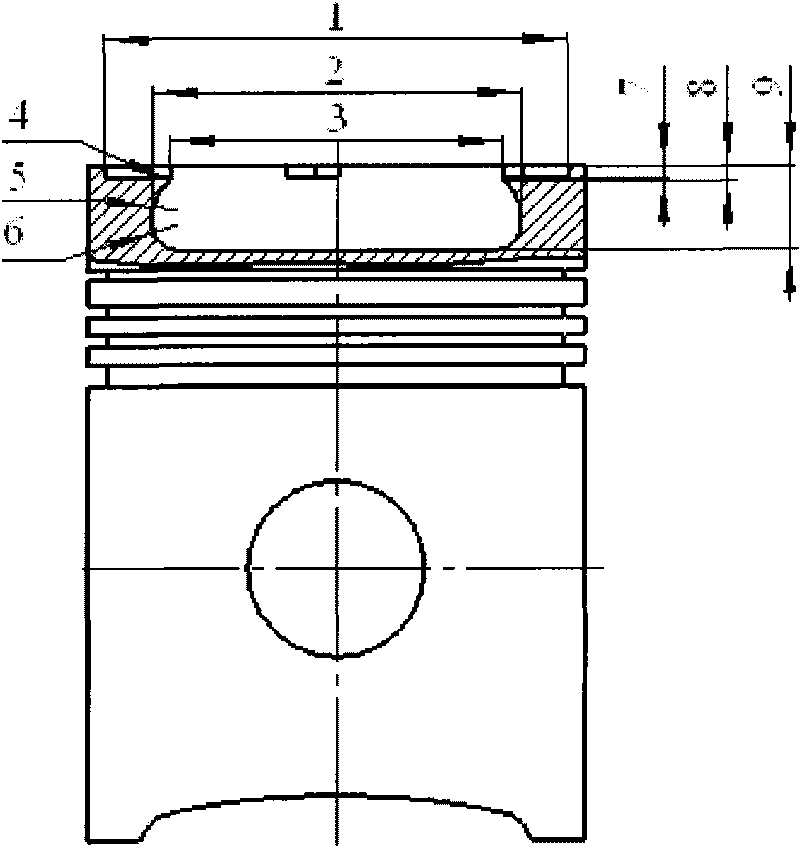

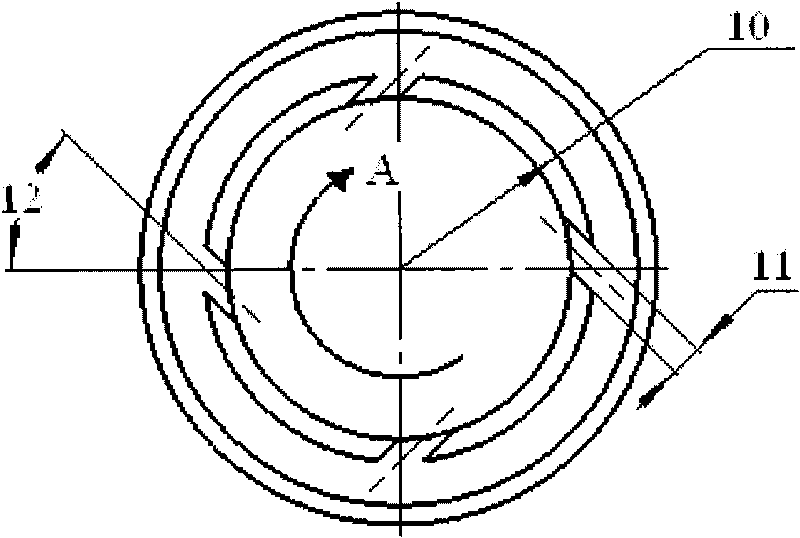

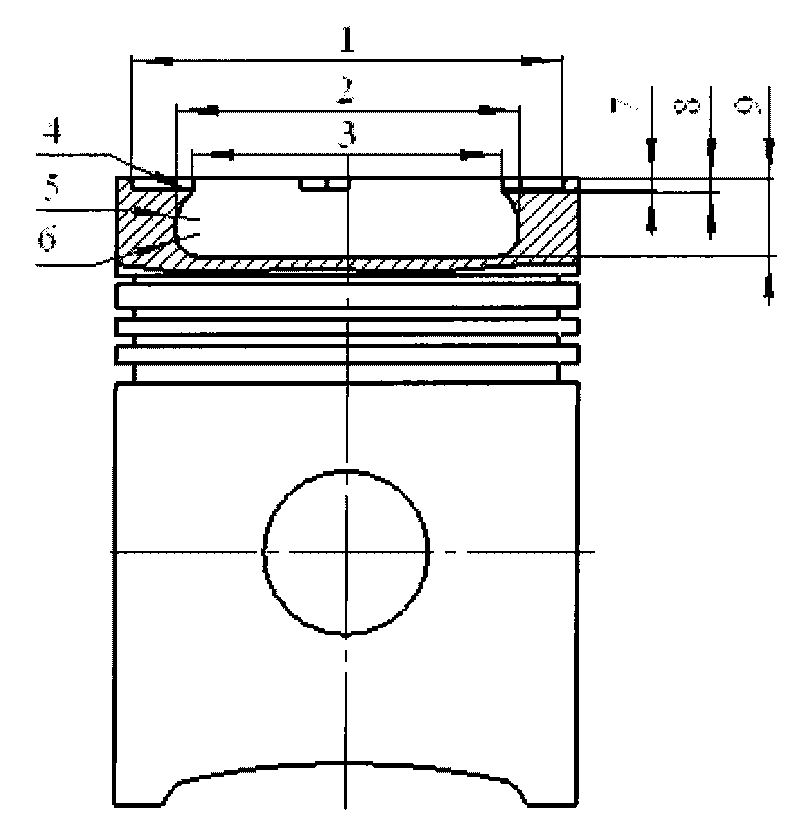

[0015] figure 1 1. The outer diameter of the ring groove of the piston head, 2. The diameter of the shallow altar-shaped combustion chamber, 3. The diameter of the constriction of the shallow al. 6. Rounded corners at the bottom of the combustion chamber, 7. The depth of the ring groove at the top of the piston, 8. The depth of the constriction of the combustion chamber, and 9. The depth of the combustion chamber. figure 2 10 piston head ring groove inner diameter, 11 inclined groove width, 12 inclined groove centerline angle.

[0016] combine figure 1 and figure 2 The combustion chamber of the lean-burn natural gas engine with medium airflow is offset. The combustion chamber is located at the top of the piston and is in the shape of a shallow altar with a neck. The structural dimensions are as follows: the diameter of the combustion chamber is 100mm, the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com