Dry-pulverized-coal gasification combined burner

A technology of combining burners and dry coal powder, applied in the direction of granular/powder fuel gasification, etc., can solve the problems of uncontrollable combustion flame diameter, easy to burn membrane type water wall, etc., to improve the degree of mixing and turbulent kinetic energy , Improve reliability and safety, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

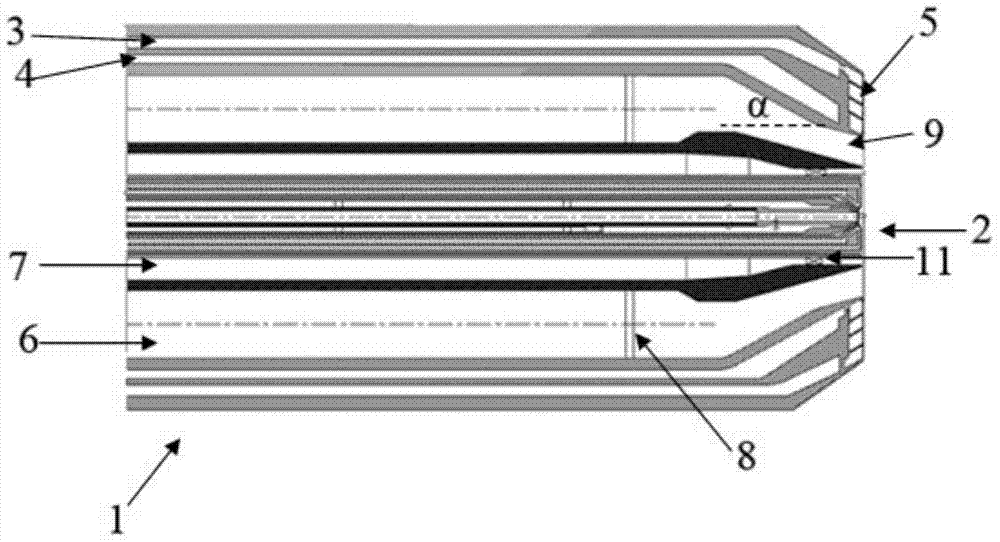

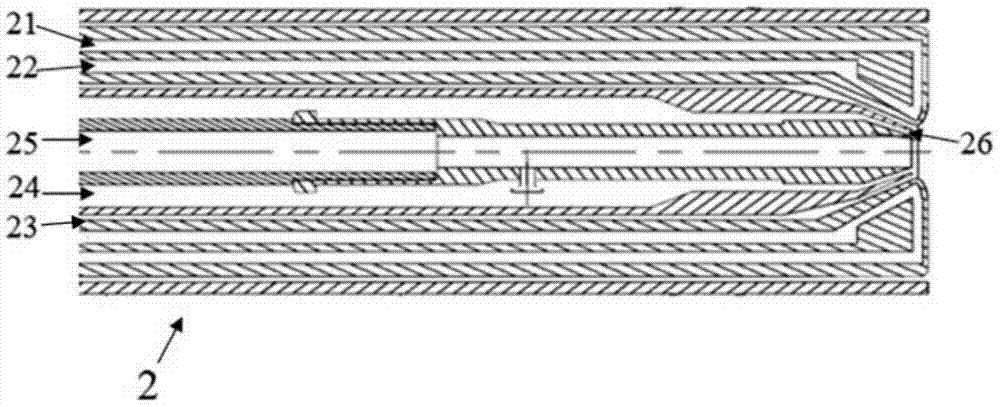

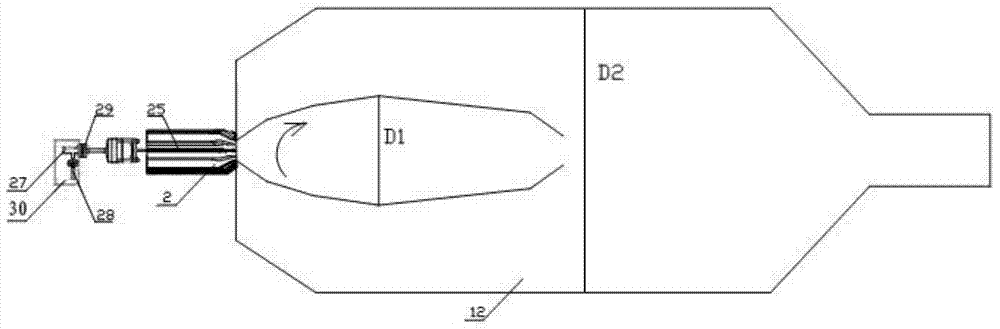

[0020] Such as figure 1 As shown, the dry pulverized coal gasification combination burner of the present invention includes a pulverized coal burner 1 and an ignition burner 2 . The main body of the pulverized coal burner 1 is cylindrical, and includes the first water-cooled jacket, coal powder channel, first oxygen channel 7 and inner cylinder from outside to inside, wherein the first water-cooled jacket includes the first water inlet channel 3, the first The water outlet channel 4 and the window-type cooling water tank 5, the first water inlet channel 3 communicates with the first water outlet channel 4 through the window-type cooling water tank 5, and the window-type cooling water tank 5 spirally coils 4 times at the fire end of the pulverized coal burner 1. The pulverized coal channel includes a pulverized coal outlet channel 9 and 3 pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com