Low temperature ethylene torch heating system

A low-temperature ethylene and torch technology, which is applied in combustion methods, fixed tubular conduit assemblies, lighting and heating equipment, etc., can solve problems such as ethylene environmental pollution, and achieve good heat exchange conditions, cost savings, and good heat transfer effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

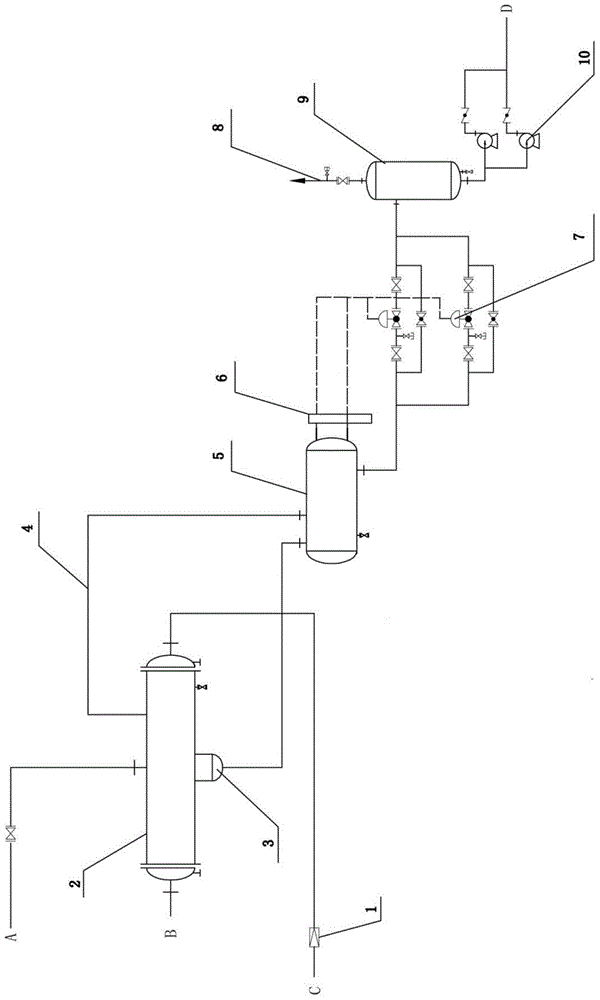

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, the present invention provides a low-temperature ethylene torch heating system, which mainly includes a low-temperature ethylene heating vaporizer 2, a saturated water condensation tank 5 and a condensate recovery tank 9, and also includes a flow detector 1, a liquid accumulation cylinder 3, a balance pipeline 4, Liquid level gauge 6, pneumatic actuator 7, venting device 8 and water pump 10.

[0018] The low-temperature ethylene heating vaporizer 2 includes a tube side and a shell side, and the tube side is fed with ethylene, the two ends of the tube side are respectively provided with ethylene inlet and outlet, and the shell side is fed with steam. The shell side of the low-temperature ethylene heating vaporizer 2 is connected with the saturated water condensation tank 5 through the connecting pipe, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com