Hydrogen production reactor using honeycomb SiC ceramic as catalyst carrier

A catalyst carrier, hydrogen production reactor technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of low power density, large pressure drop, easy catalyst falling off, etc., to improve heat transfer performance, heat The effect of uniform distribution and improved heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

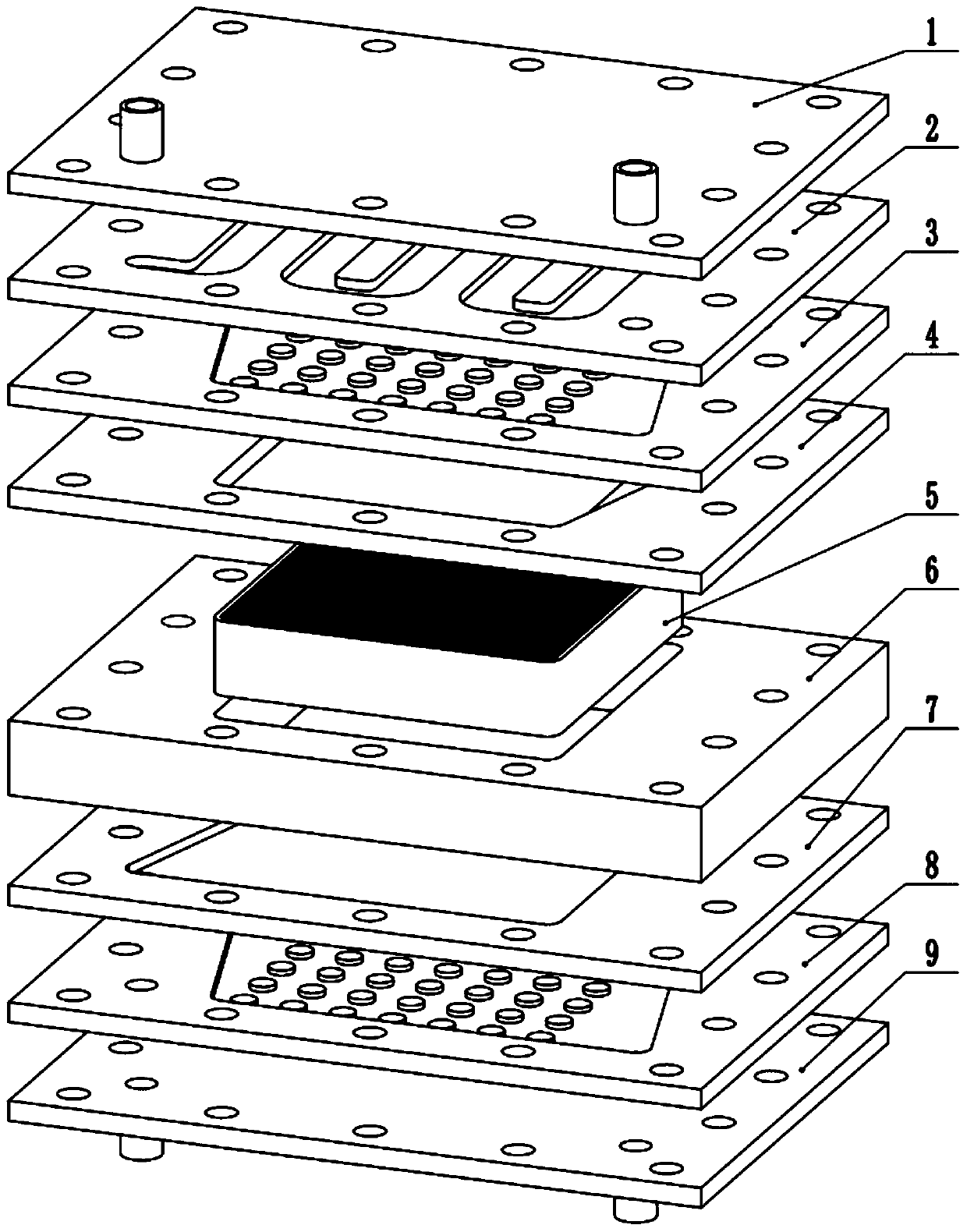

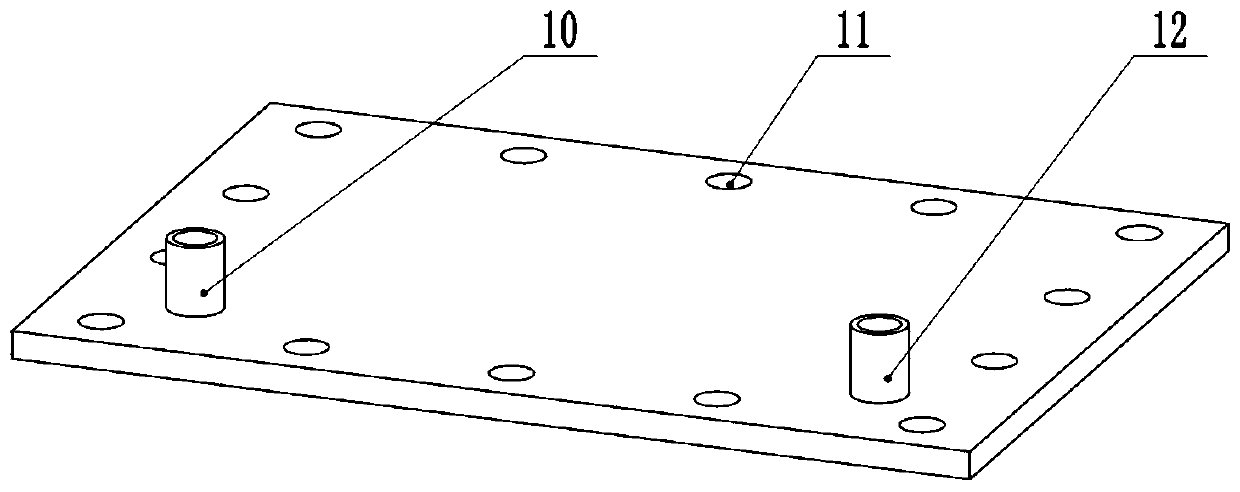

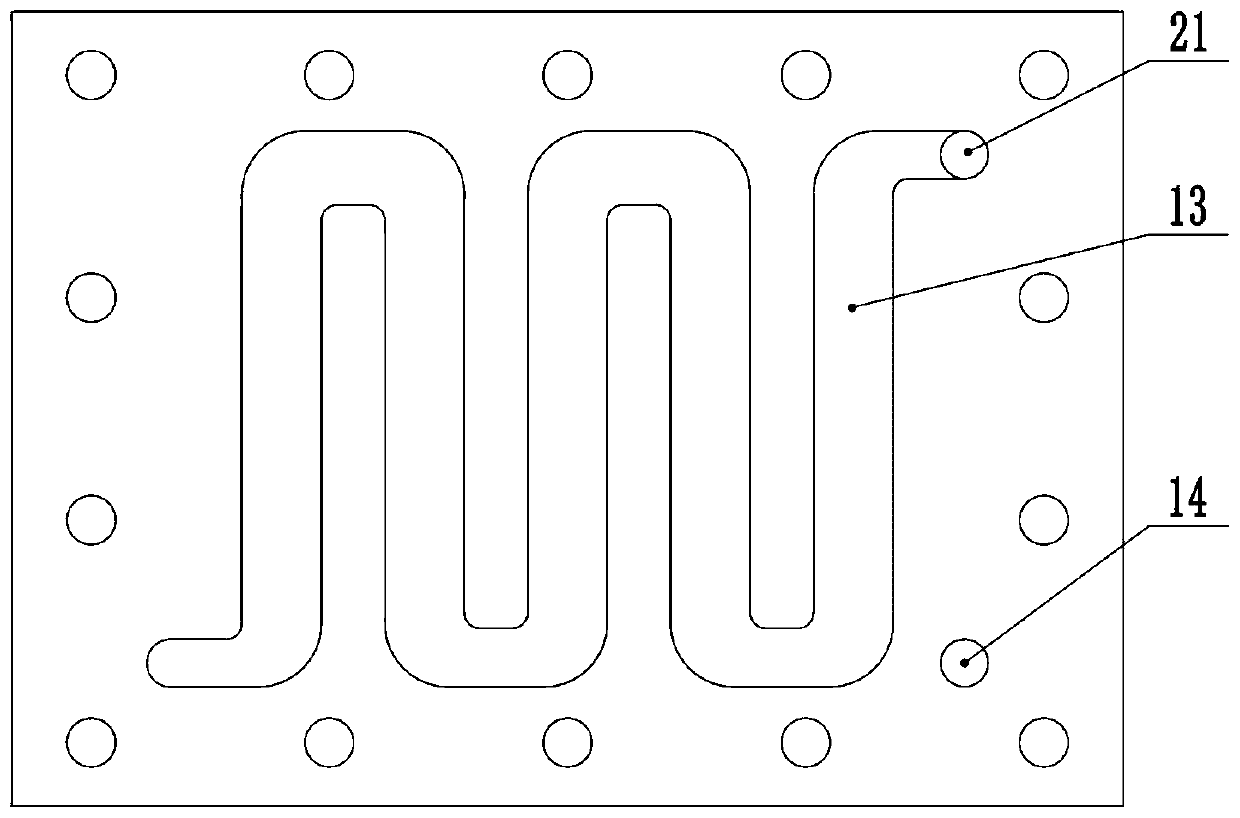

[0039] Such as figure 1 As shown, the reactor includes an upper cover plate 1, an evaporation plate 2, a first catalytic combustion plate 3, a reforming cavity upper cover plate 4, a honeycomb SiC ceramic 5, and a methanol water vapor reforming plate 6, which are stacked in sequence from top to bottom. , the lower cover plate 7 of the reforming chamber, the second catalytic combustion plate 8 and the lower cover plate 9; the peripheral edges of each plate are provided with a plurality of positioning bolt holes 11 arranged at intervals along the circumference, and the bolts pass through each plate coaxially The locating bolt holes 11 fasten the boards together; in specific implementation, flexible graphite gaskets are placed between two adjacent boards, which are fastened by bolts, so that the two boards can be effectively sealed.

[0040] Such as fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com