Sea water fresh water two-purpose spiral-tube condenser

A condenser and spiral tube technology, applied in the field of refrigeration equipment, can solve problems such as troublesome maintenance, complicated pipelines, and many parts, and achieve the effects of less solder joints, good heat exchange, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

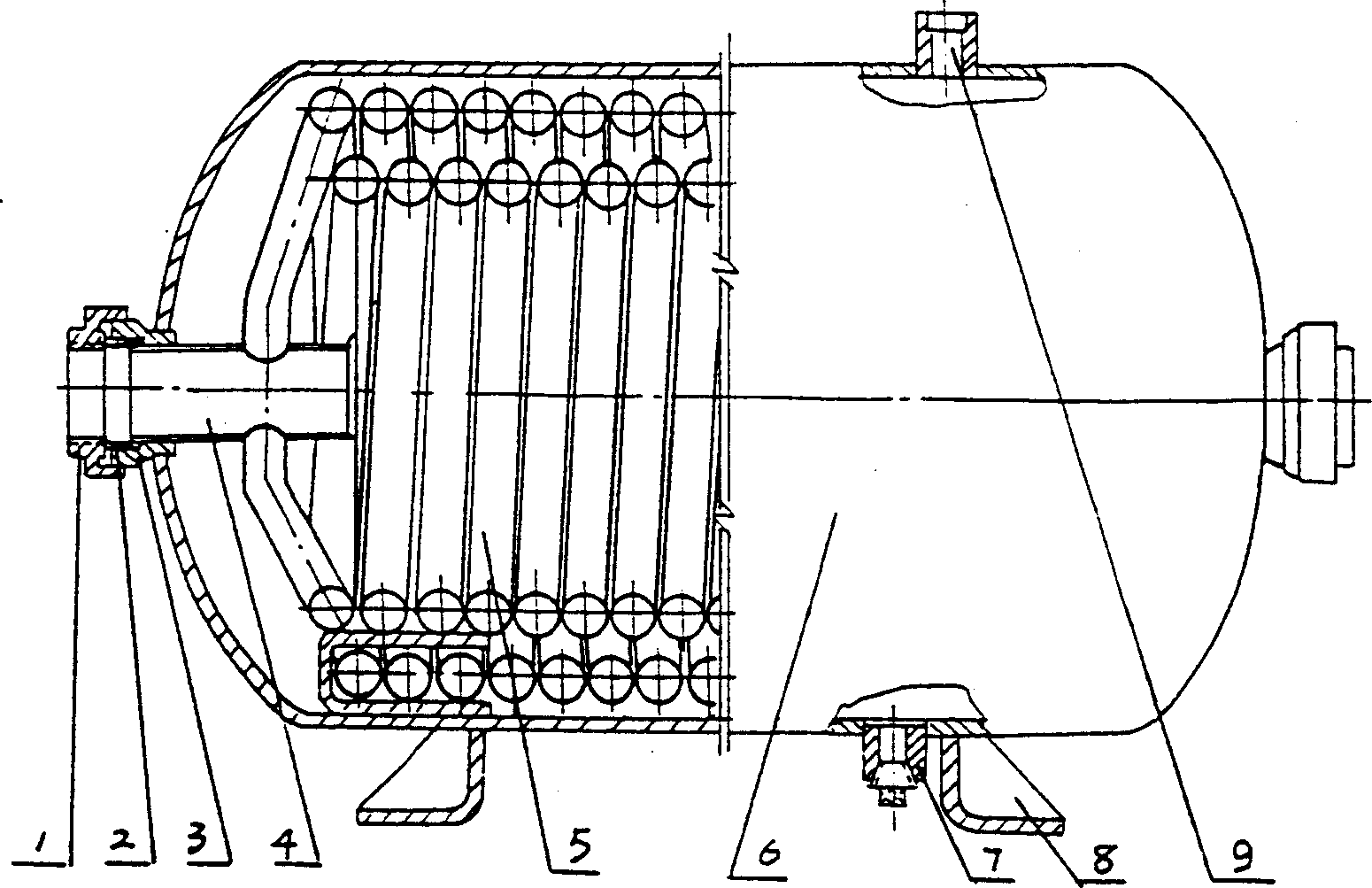

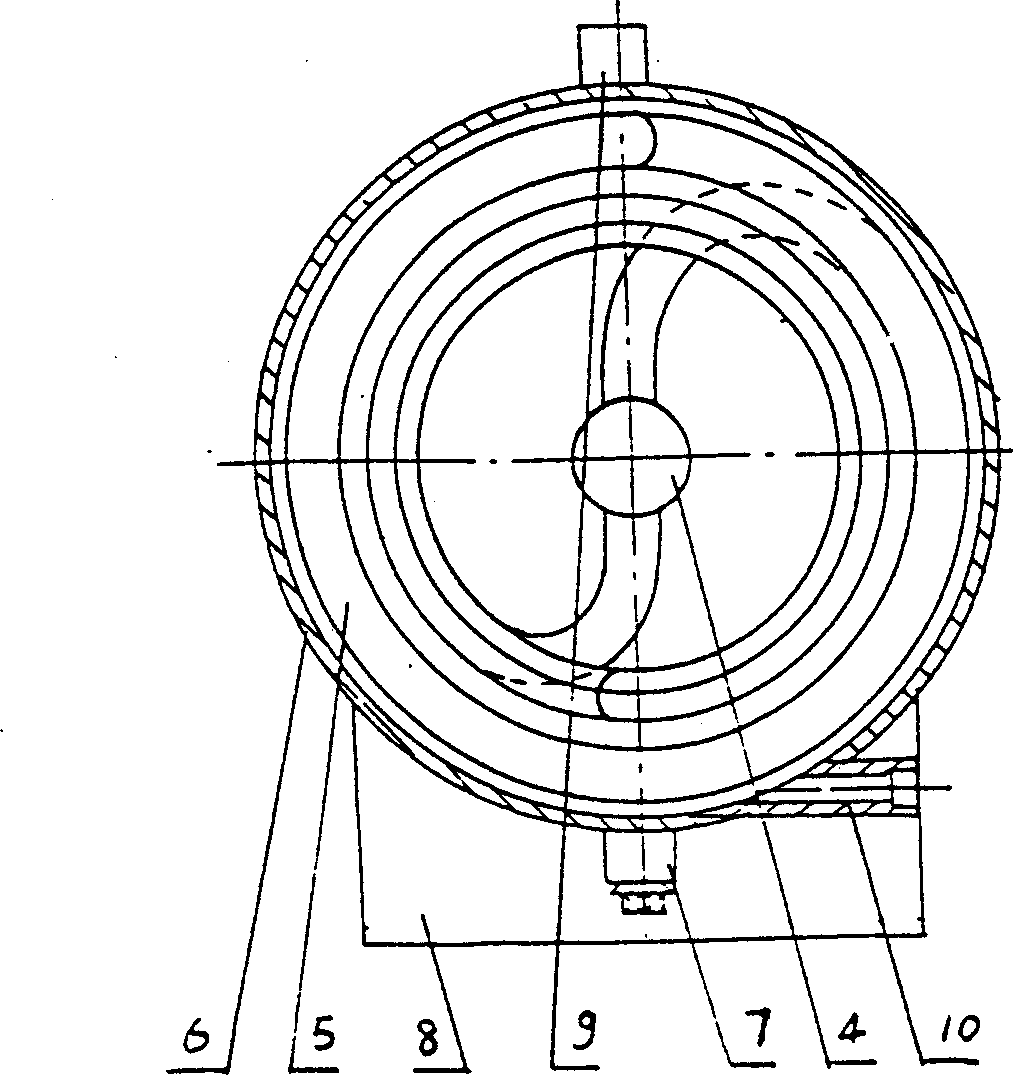

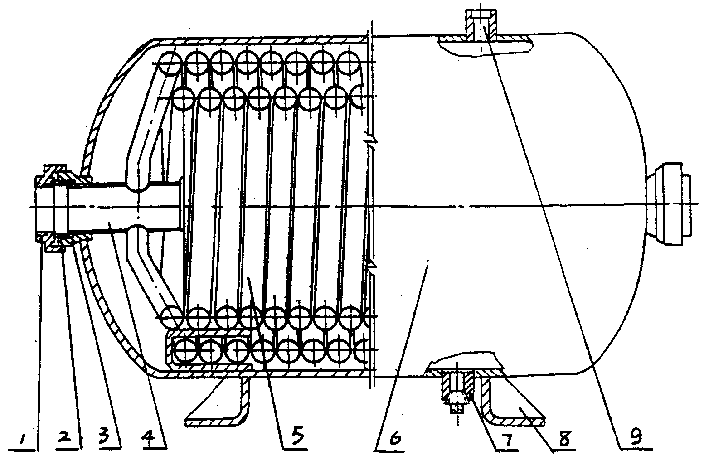

[0012] The specific implementation of the present invention will be further described below in conjunction with accompanying drawing:

[0013] Such as figure 1 , figure 2 As shown, the present invention mainly includes a header compression cover 1, a compression ring 2, a header positioning seat 3, a header 4, a spiral tube 5, a casing 6, a liquid discharge valve 7, a support 8, and a steam inlet pipe seat 9. Outlet pipe seat 10.

[0014] The casing 6 is a closed hollow cylinder with spherical surfaces at both ends. A header 4 is installed at both ends of the casing 6, and the header 4 is made of a titanium alloy tube. Smooth titanium alloy tubes are rolled into spiral tubes 5 of two diameters in parallel without gaps, coaxially stacked on each other, and the radial distance is consistent. The two ends of the two spiral tubes 5 are welded into one body with the two headers 4. fixed in the housing 6. Two manifold 4 ports are welded with manifold positioning seat 3, and ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com