Method for enhancing gas-liquid mass transfer of ebullated bed hydrogenation reactor

A hydrogenation reactor and enhanced boiling technology, which is applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems affecting the reaction conversion rate and not considering the optimization of gas distribution, so as to save investment costs and reduce daily operating costs , the effect of improving mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

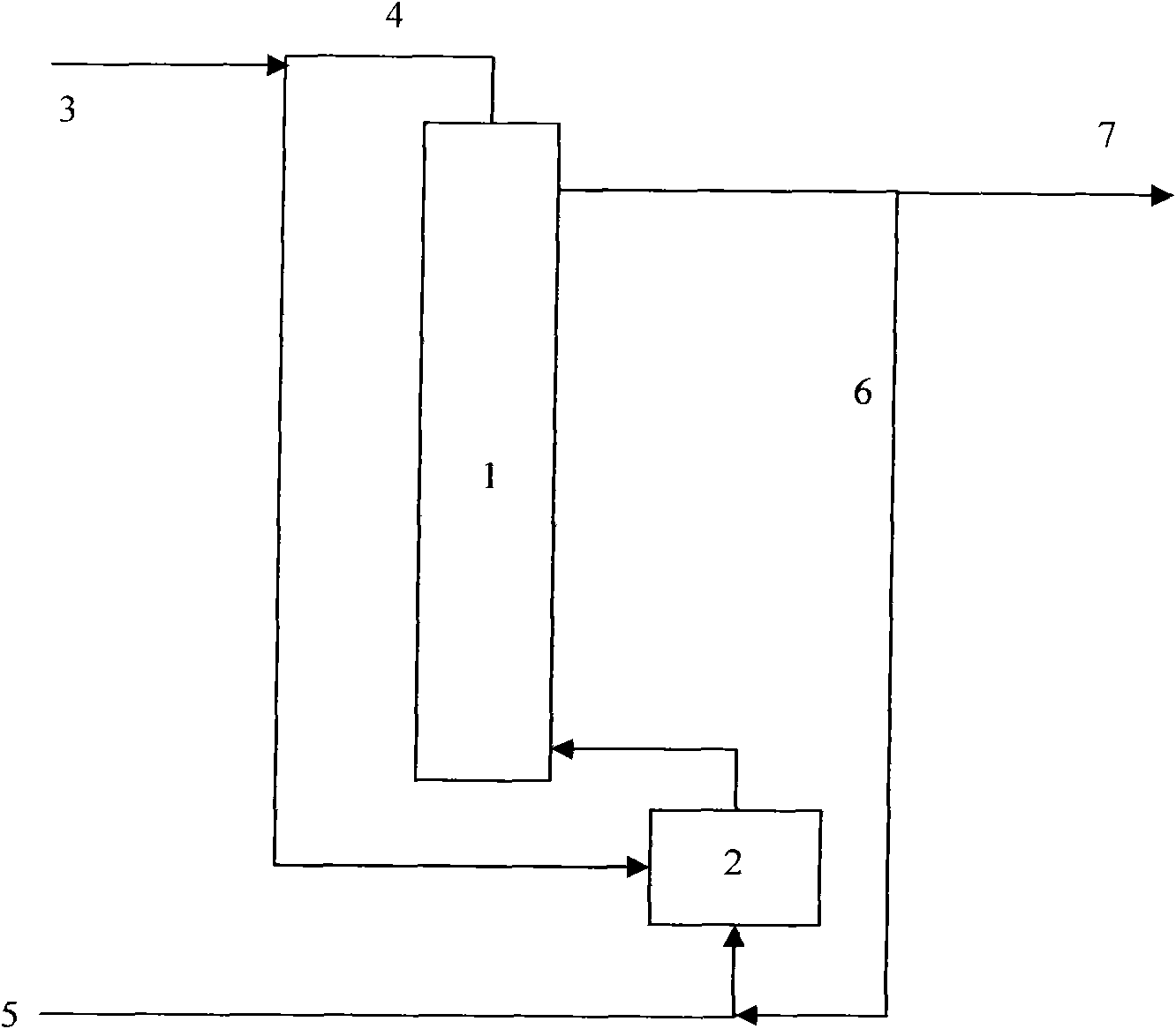

[0034] This example is an implementation of residual oil hydrotreating, and the schematic diagram of the operation process refers to the figure 1 .

[0035] Fresh raw material oil 5 and circulating oil 6 are mixed into liquid phase materials in the pipeline, the volume ratio of circulating material and fresh raw material is 1:1, fresh hydrogen 3 and circulating hydrogen 4 are also mixed in the pipeline, and then the liquid phase materials and mixed Hydrogen enters the microbubble generator 2 for gas-liquid enhanced distribution. The liquid phase material with fully dissolved hydrogen and a large number of microbubbles directly enters the ebullated bed reactor 1, and contacts with the catalyst for hydrogenation and cracking reactions. The hydrogen after the reaction is recycled, part of the liquid material is recycled into the microbubble generator, and part of it enters the fractionation system as the generated oil 7 .

[0036] The ebullating bed hydrogenation catalyst is mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com