Dehydration drying method capable of improving bearing capacity of dredged sediment stock dump

A technology for dredging sediment and bearing capacity, which is applied in the fields of soil protection, construction, and infrastructure engineering, etc. It can solve the problems of reducing the drying speed of dredged sediment, low land utilization rate, secondary pollution, etc., and achieve faster muddy water Separation rate, reduce energy consumption, and improve the effect of sediment bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

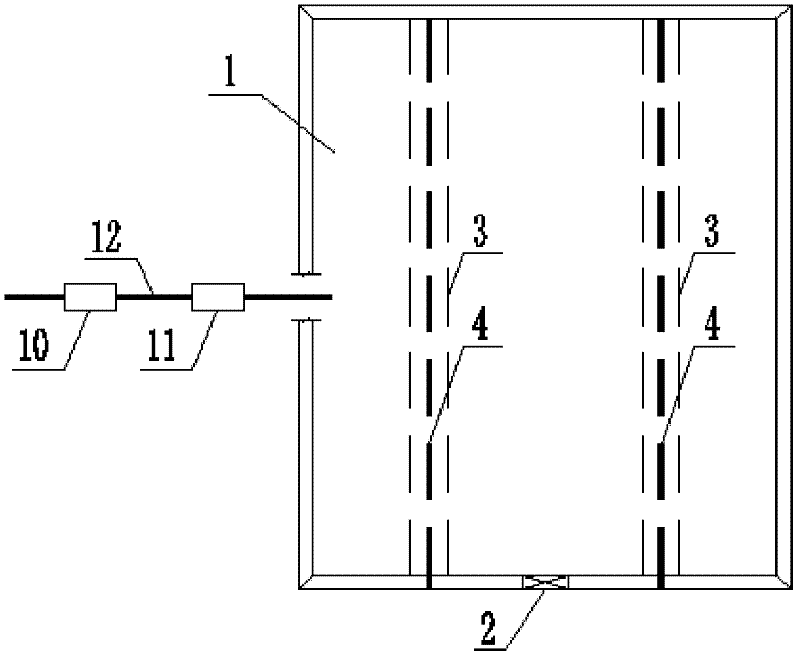

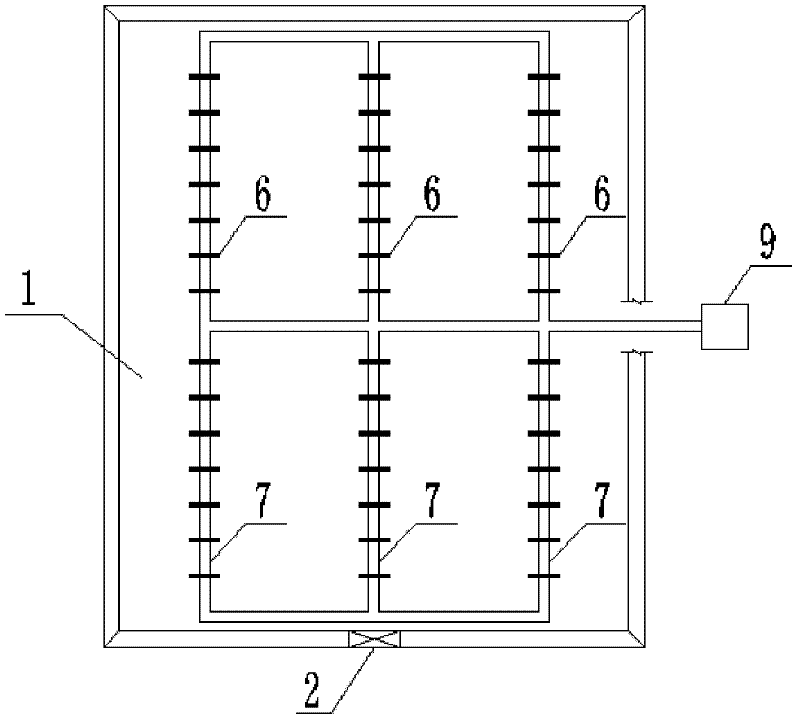

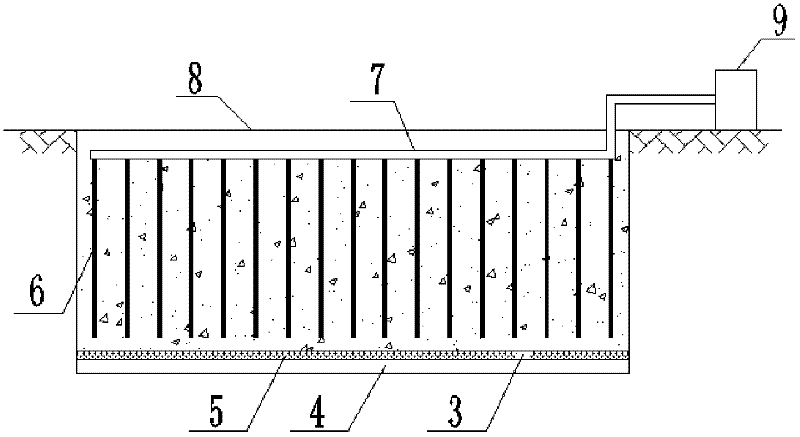

[0032] The yard structure that the present invention builds is as figure 1 , figure 2 , image 3 As shown, including: 1 sediment storage yard, 2 drainage outlet, 3 drainage ditch, 4 drainage pipe, 5 gravel, 6 plastic drainage board, 7 plastic water collection pipe, 8 sealing film, 9 external vacuum system, 10 dehydrating agent mixer , 11 improver mixer, 12 mud pipe.

[0033] Such as figure 1 , figure 2 , image 3 As shown, the present invention builds a drainage system in the bottom mud stockyard, and the drainage system is composed of an upper drainage outlet 2, a lower drainage ditch 3 and a drainage pipe 4, and a plastic drainage board 6 running through the middle.

[0034] Firstly, a drainage outlet 2 is set on one side of the sediment storage yard 1, the lower side of the drainage outlet 2 is 1-1.2m away from the bottom of the storage yard, and the upper side of the drainage outlet 2 is flush with the top of the storage yard. The width of the drain outlet 2 is 1.2...

Embodiment 2

[0043] A dehydration and drying method capable of improving the bearing capacity of a dredged sediment stockpile, which adopts the following steps: after the dredged mud is evenly mixed with a dehydrating agent and a modifier, it enters a stockyard surrounded by a cofferdam; Vacuum dehydration devices are installed at the drain outlet and the top of the storage yard, and several drainage ditches, drainage pipes and seepage gravels are arranged parallel to each other at the bottom of the storage yard. Among them: the drainage pipes are laid in the drainage ditch, wrapped with non-woven fabrics outside, and the seepage gravels are set on Between the drainage ditch and the drainage pipe, holes are drilled around the pipe wall of the drainage pipe, and the drainage outlet is arranged on the edge of the cofferdam on one side of the stockyard.

[0044] The dehydrating agent used is PAC or FeCl 3 , what adopted in the present embodiment is PAC, and improving agent can be the fly ash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com