High pressure safety valve detection system

A detection system, high-pressure safety technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems such as the need to verify the numerical accuracy, the influence of the working environment of the equipment, the large volume of the electric hydraulic pump, etc., and achieve good economic benefits. and social benefits, shorten the downtime and maintenance time, and the effect of simple and quick maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

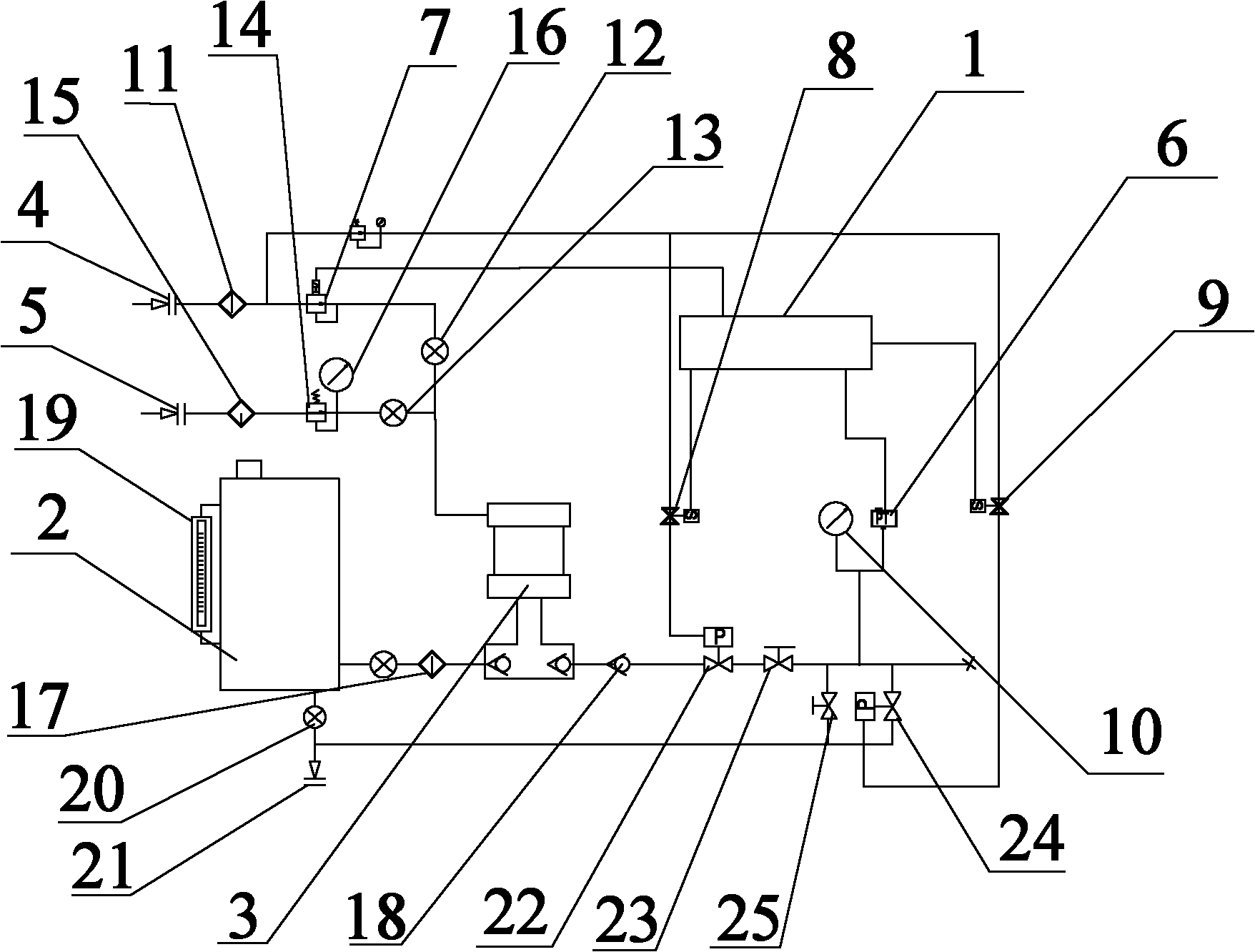

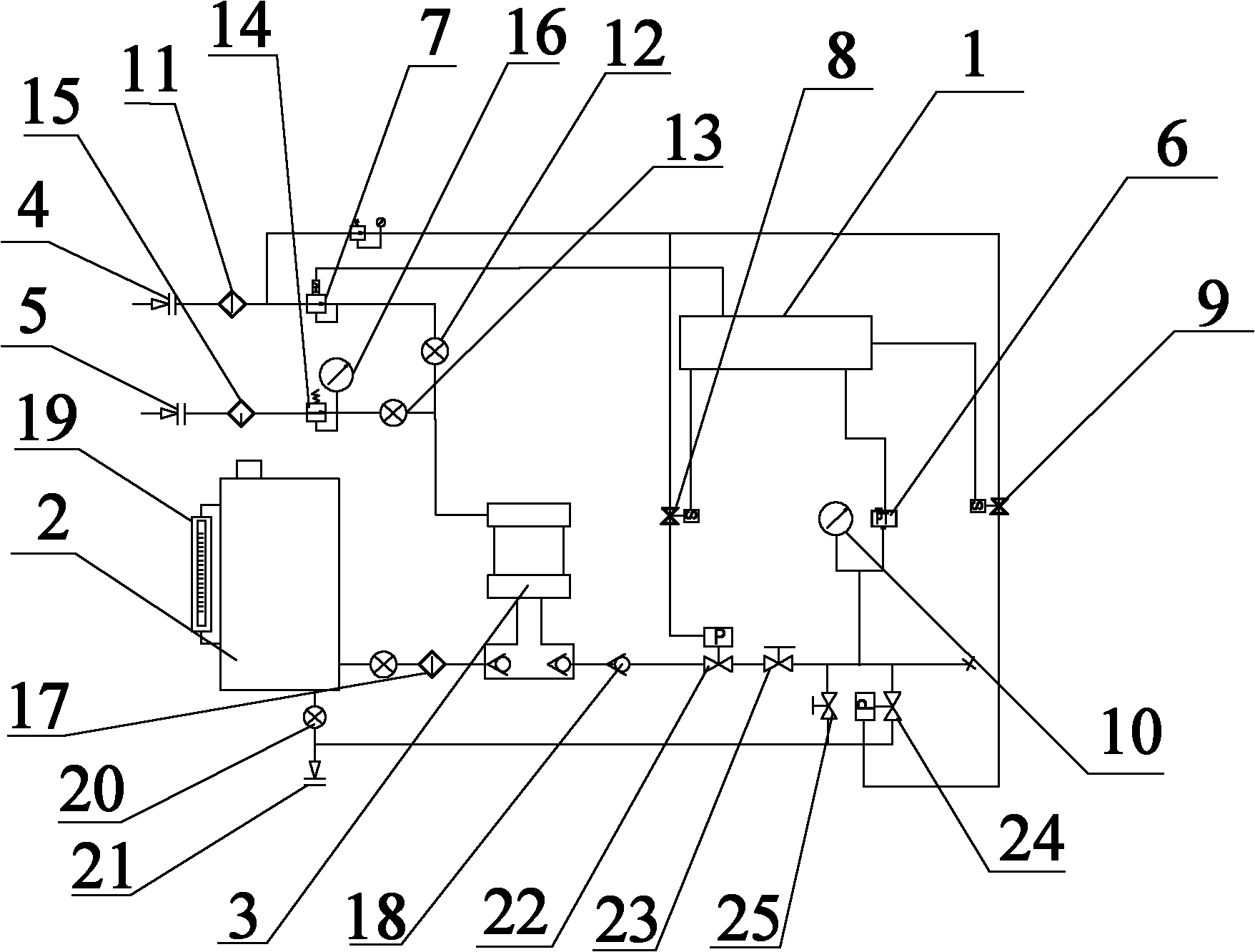

[0015] Such as figure 1 As shown, a high-pressure safety valve detection system according to an embodiment of the present invention includes a control system 1 and a water tank 2, and the control system 1 is respectively connected to a pressure sensor 6, an electric pressure regulating valve 7, a first solenoid valve 8 and a first solenoid valve 8. Two electromagnetic valves 9, the pressure sensor 6 is connected with a double-needle pressure gauge 10, the first electromagnetic valve 8 and the second electromagnetic valve 9 are connected in parallel and both are connected to the first air filter 11, and the two ends of the first air filter 11 are respectively connected to the second One drives the air inlet 4 and the electric pressure regulating valve 7, the other end of the electric pressure regulating valve 7 is connected to the first speed regulating valve 12, the first speed regulating valve 12 is connected to the booster pump 3 and the second speed regulating valve 13, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com