Technique for cleaning acid dirty of acid reactivating machine group inner loop type pipeline

A technology of acid regeneration and internal circulation, which is applied in the field of steel rolling auxiliary equipment, can solve the problems of consuming a lot of manpower and material resources, and achieve the effects of high cleaning efficiency, thorough cleaning of acid scale, and reduced failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

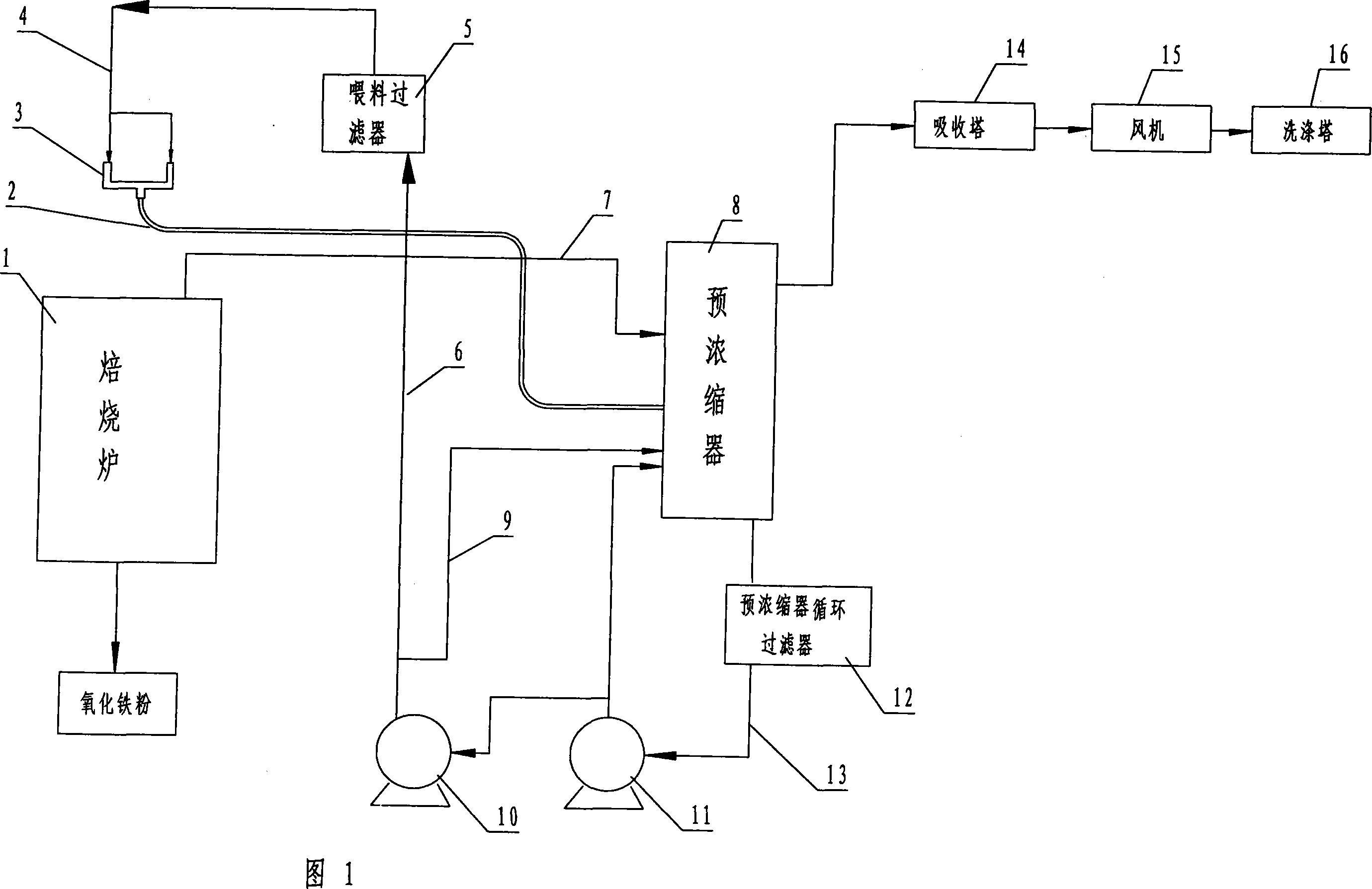

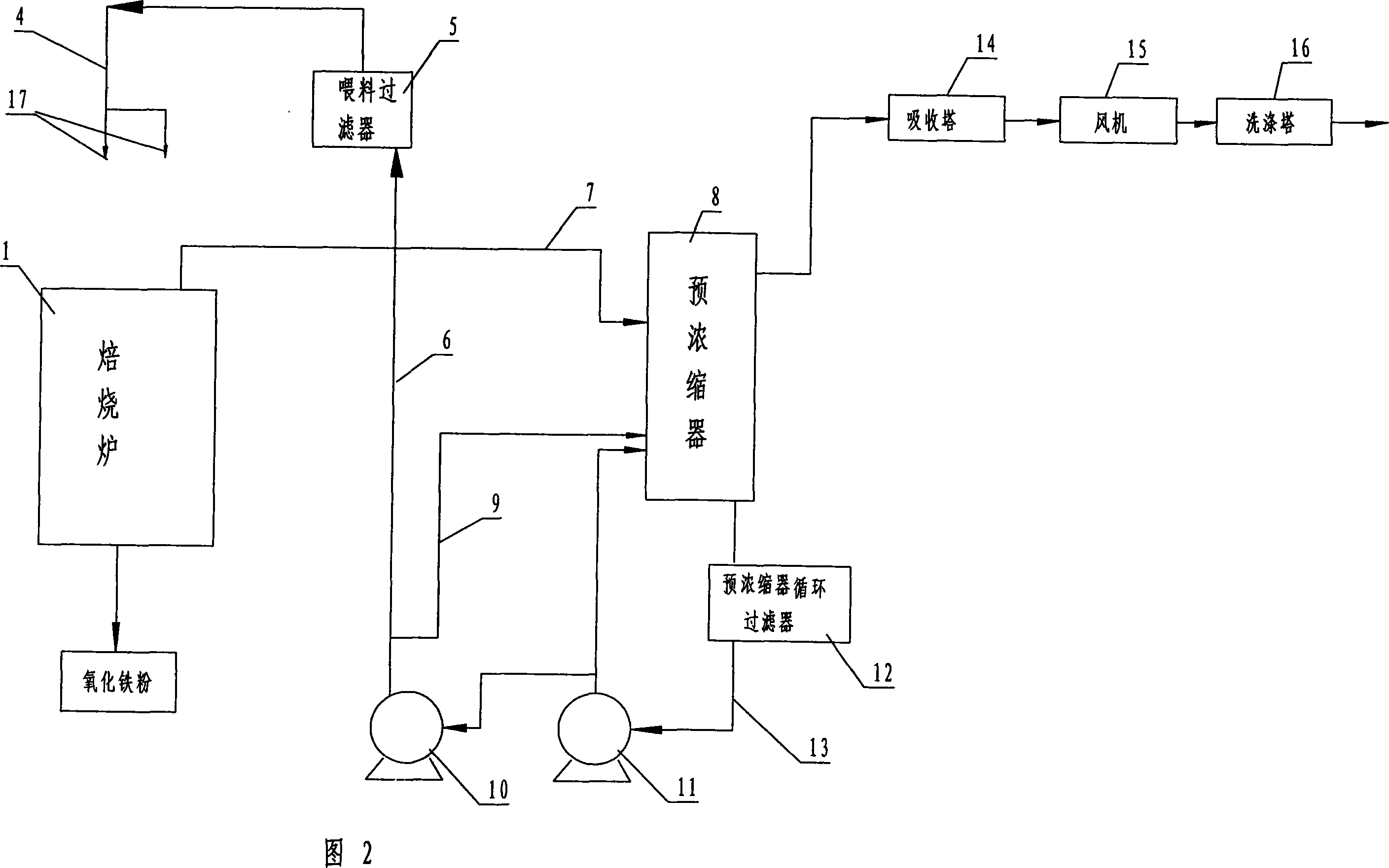

[0017] The method of the present invention utilizes the equipment of the acid regeneration unit and adds a tee 3 and a high-pressure acid-alkali-resistant connecting hose 2 to establish a lye flushing circulation loop without external equipment, forming an internal circulation pipeline acid scale cleaning process. Below in conjunction with Fig. 1, the specific embodiment of the present invention is described in detail:

[0018] 1. The bottom of the pre-concentrator 8 of the acid regeneration unit is a lye solution pool, and the first lye is composed of a circulation pump 11, a pre-concentrator circulation filter 12, and a 30-meter circulation pipeline 13 of the pre-concentrator to be cleaned of acid scale Flush the circulation loop. Connect the two connecting ports of the added tee 3 with the two spray guns respectively, and connect the other connecting port with the connecting rubber hose 2, and use the feeding pump 10, the feeding filter 5, the 40-meter feeding pipeline 6 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com