Method for removing impurities of vacuum chuck

A technology for vacuum suction cups and sundries, which is applied in the direction of cleaning devices, conveyor objects, transportation and packaging, etc. It can solve the problems of affecting the vacuum degree of the vacuum circuit, reducing production efficiency, and failing to suck products, so as to reduce the frequency of downtime and maintenance. Improved production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

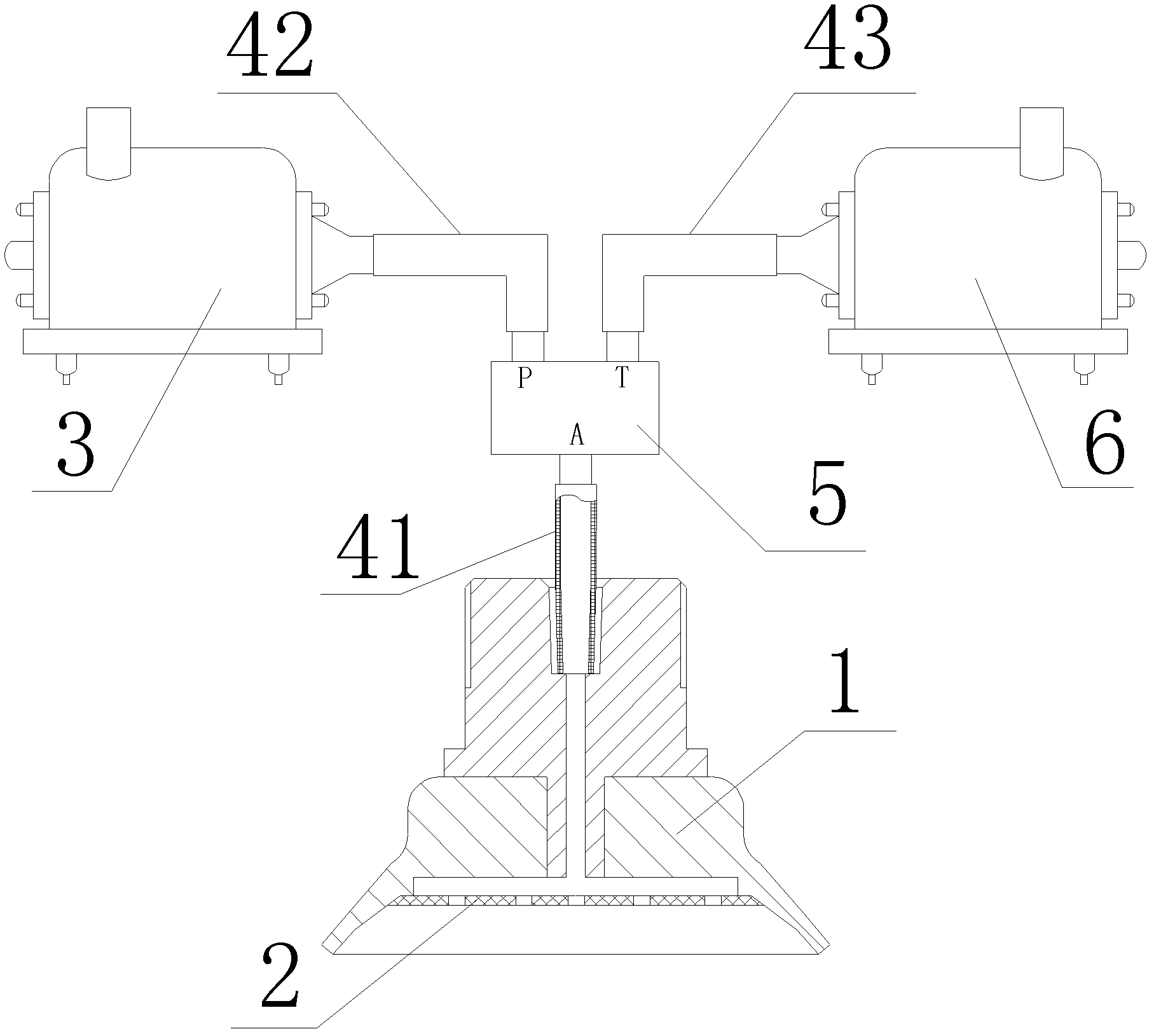

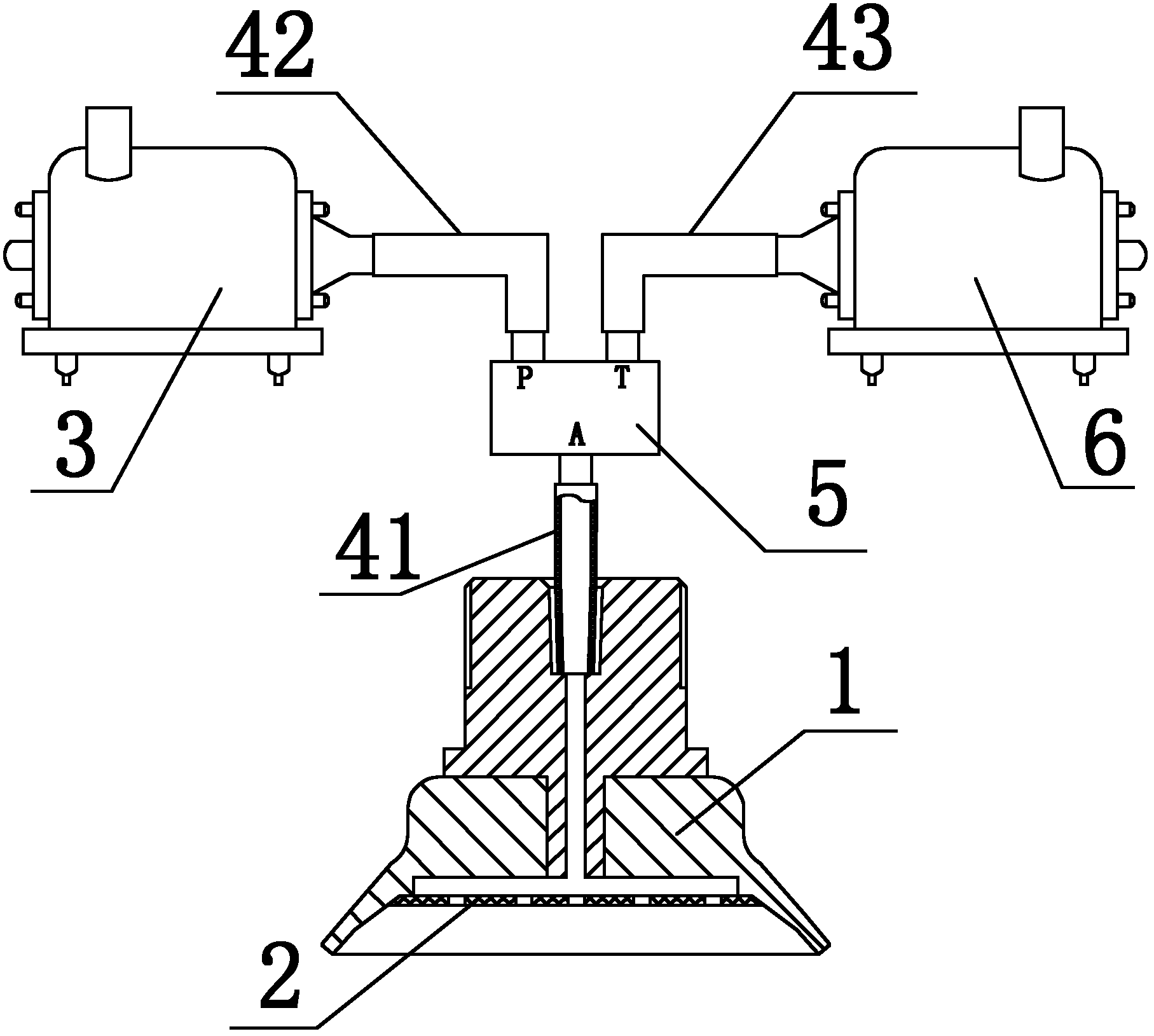

[0012] When the printed circuit board is carried by the vacuum suction cup, the suction cup 1 is pressed on the workpiece at the first station, the vacuum pump 3 is started, and a negative pressure is formed in the suction cup 1, and the suction cup 1 sucks up the workpiece, and the workpiece follows the suction cup 1 to the second station. Move, after arriving No. 2 station, vacuum pump 3 closes, and workpiece falls. Suction cup 1 returns to No. 1 station and repeats the above steps.

[0013] During the punching process of the printed circuit board, debris and other debris will be generated, and the debris will remain in the hole and on the surface of the circuit board. When the suction cup 1 sucks the circuit board, the sundries will be sucked into the airway and attached to the filter screen 2 and the pipeline, affecting the vacuum degree of the airway. Therefore, after the suction cup 1 puts down the workpiece, the air blowing pump 6 is started to form a positive pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com