Lime-coke-calcium carbide production joint apparatus

A combined device and limestone technology, applied in lime production, coke oven, petroleum industry and other directions, can solve the problems of increasing the pollution of calcium carbide furnace, high recovery cost, unfavorable quicklime, etc., to extend the production cycle and equipment service life, and reduce energy consumption. and production costs, the effect of reducing the number of downtimes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

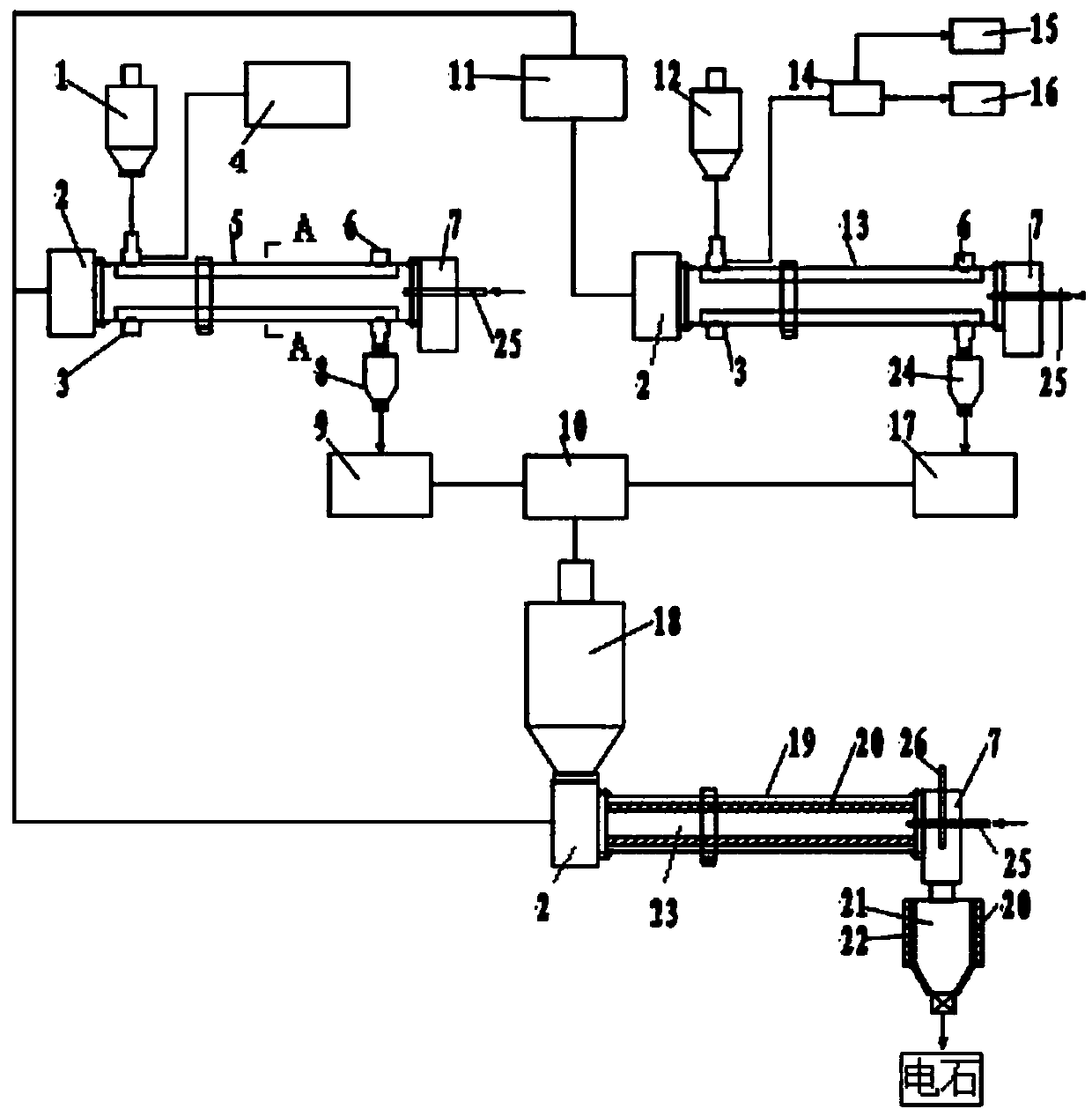

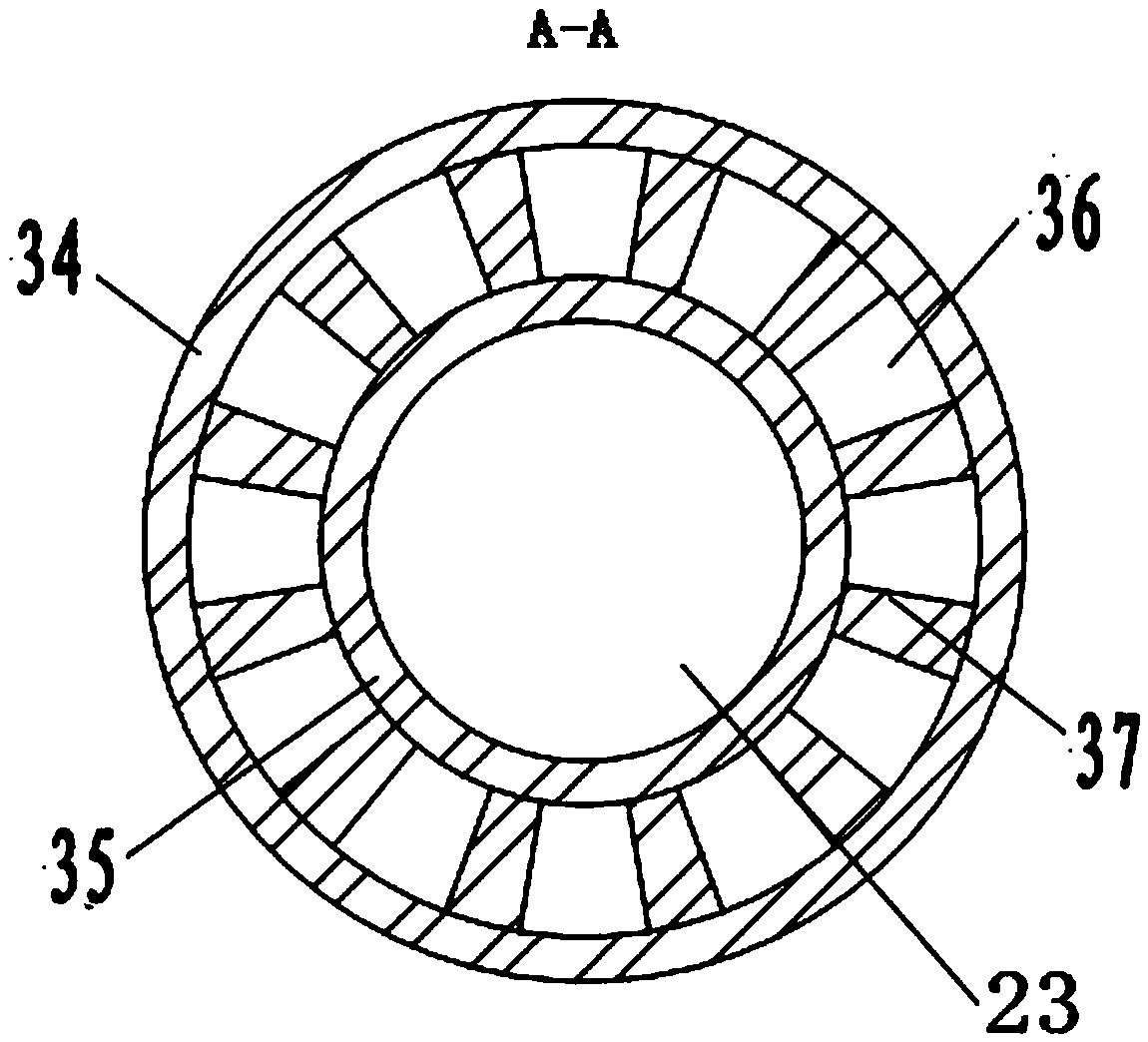

[0021] Lime, coke and calcium carbide production unit of the present invention such as figure 1 , Figure 4 As shown, it includes a lime rotary kiln, a coking rotary kiln, a calcium carbide rotary kiln 19, a carbon dioxide recovery unit 4 and a mixing briquette equipment 10. The lime rotary kiln is a partition lime rotary kiln 5 , and the coking rotary kiln is a partition coking rotary kiln 13 . Lime rotary kiln is equipped with limestone silo 1, lime cooler 8 and lime silo 9; coking rotary kiln is equipped with coal powder silo 12, coke cooler 24 and coke powder silo 17; calcium carbide rotary kiln is equipped with calcium carbide raw material silo 18 and calcium carbide outlet Silo 21. Such as figure 2As shown, the dividing wall lime rotary kiln and the dividing wall coking rotary kiln are respectively composed of an inner ring 35 and an outer ring 34 installed coaxially. The material channel is provided with a refractory support 37 . The limestone silo is connected to...

Embodiment 2

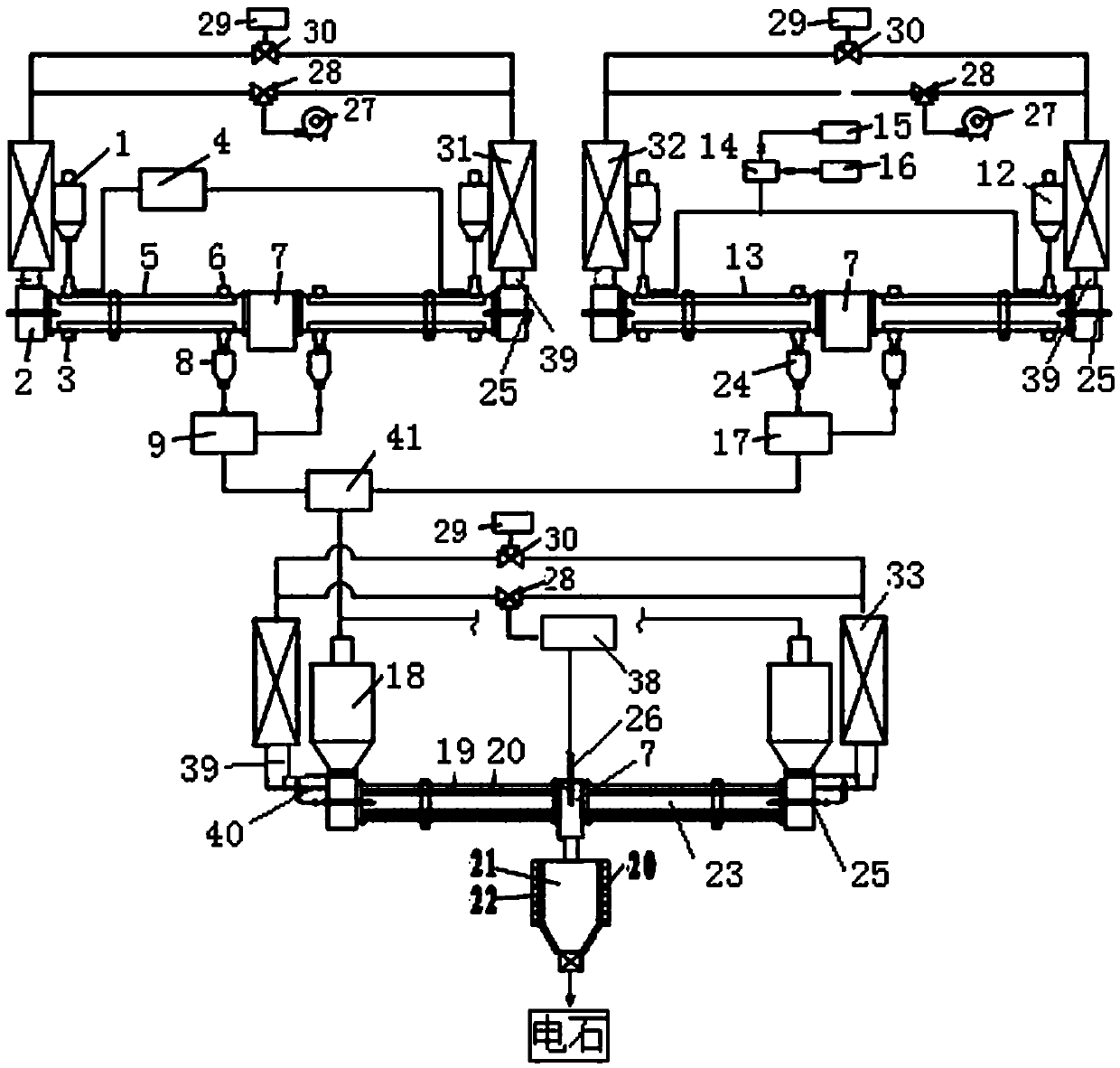

[0027] Another embodiment of the present invention is as image 3 As shown, it includes two partition lime rotary kilns 5, two partition wall coking rotary kilns 13 and two calcium carbide rotary kilns 19. 7 are connected, and the two calcium carbide rotary kilns are connected through the kiln head cover 7. Each partition lime rotary kiln is equipped with limestone silo 1, lime cooler 8 and limestone heat accumulator 31, and each partition wall coking rotary kiln is equipped with coal powder silo 12, coke cooler 24 and coal powder heat accumulator 32, Each calcium carbide rotary kiln is equipped with a calcium carbide raw material heat accumulator 33 and a calcium carbide raw material bin 18, and the two calcium carbide rotary kilns share a calcium carbide discharge bin 21. The limestone heat accumulator is connected with the partition lime rotary kiln through the kiln tail cover, the pulverized coal heat accumulator is connected with the partition wall coking rotary kiln thr...

Embodiment 3

[0031] Other structure and operation process of present embodiment are identical with embodiment 2, as Figure 4 As shown, the kiln chamber 23 of the rotary kiln and the inner wall of the discharge bin 21 are coated with a self-fluxing refractory material layer 20, and the rotary kiln can produce metals such as aluminum, manganese, silicon, nickel and iron. The material layer is a mixture of the oxides of the above metals and carbon and its auxiliary raw materials, and the pressed refractory material is paved on the inner wall of the rotary kiln and the discharge bin. The rotary kiln can burn glass or other high-temperature calcined materials, and the temperature of the fired glass or other high-temperature calcined materials must not be lower than 1500 0 c. The operating mode of the dividing wall rotary kiln is the same as in Example 2.

[0032] When the rotary kiln produces Si or SiC, the chemical formula is SiO 2 +C+F reacts at high temperature to form Si, or SiO 2 +C+F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com