Flexile deformation proof urinal pad premix paper urinal pad and production method of paper urinal pad

A premixed, anti-deformation technology, applied in the field of diaper pads, can solve the problems of accelerating the instantaneous absorption and absorption speed of diapers, and achieve the effect of strong toughness and high comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

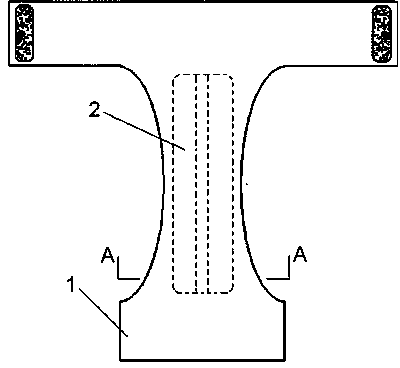

[0039] Example: A preferred embodiment of the present invention is,

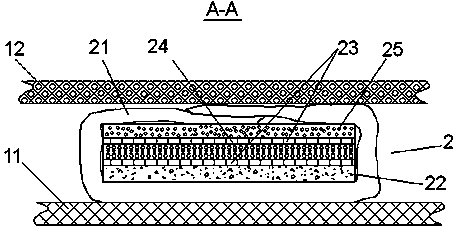

[0040] First, a 210mm wide dust-free paper 21 is used as a cushion layer in the mixed absorption layer of fluff pulp and SAP to play the role of covering and fixing;

[0041] Secondly, the fluffy cloth layer 24 with a width of 95mm is applied with high-absorbent resin SAP23 on the upper and lower sides, which constitutes the core absorbent core layer to absorb and lock water;

[0042] Thirdly, the wet strength paper layer 25 sizing is used as a pad on the core absorbent core layer to prevent the high-absorbent resin from moving out;

[0043] Finally, the surrounding sheet 1 is composed of the breathable composite film 11 and the perforated non-woven fabric 12, and the core body 2 is sandwiched between the breathable composite film 11 and the perforated non-woven fabric 12, and the core body 2 is located on the human body of the surrounding sheet 1. The corresponding position of the gear part. The left an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com