Honeycomb SCR smoke denitration catalyst embryoid body and preparation method thereof

A technology of denitrification catalyst and honeycomb shape, which is applied in the field of honeycomb SCR flue gas denitrification catalyst body and its preparation. Excellent, high denitrification efficiency, high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

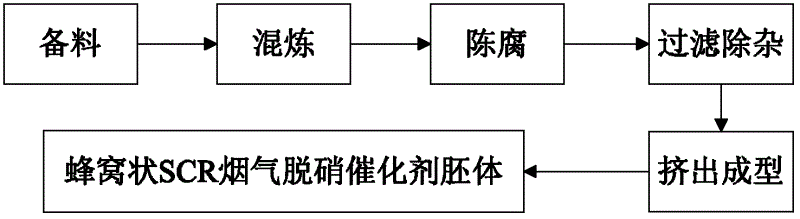

Method used

Image

Examples

Embodiment 1

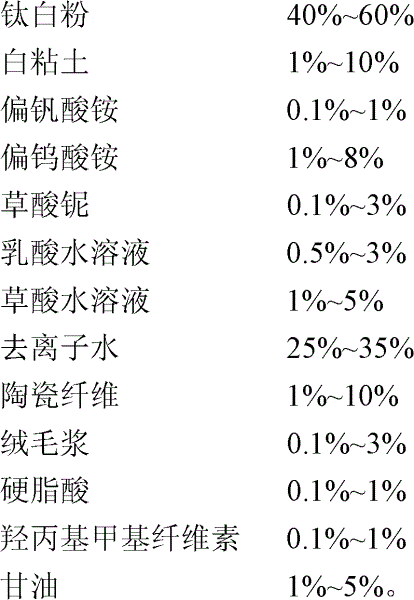

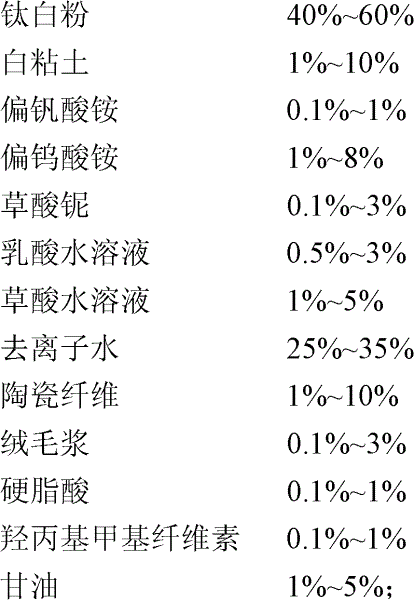

[0026] Example 1 Preparation of honeycomb SCR flue gas denitration catalyst embryo body

[0027] Stir and mix 10 g of ammonium metavanadate, 20 g of ammonium metatungstate, 25 g of niobium oxalate and 20 ml of an aqueous oxalic acid solution with a concentration of 60% by mass at 50°C to obtain a mixed solution;

[0028] Put 412g of titanium dioxide, 80g of white clay, 10ml of lactic acid aqueous solution with a concentration of 50% by mass, 3g of stearic acid, 275ml of deionized water, and the above mixed solution into a mixer and kneaded once at 80°C for 42min. Then add ceramic fiber 80g (F-1260 type ceramic fiber, Zhejiang Deqing Lanya Crystal Fiber Co., Ltd.), fluff pulp 3g (Hubei Daye Xinwen Fiber Material Processing Factory), hydroxypropyl methylcellulose 2g, glycerin 20ml and 40ml of deionized water were mixed for the second time, and the mud embryo was obtained after mixing for 15min;

[0029] Wrap the mud embryo with plastic film, put it in a cool and humid place (th...

Embodiment 2

[0032] Example 2 Preparation of honeycomb SCR flue gas denitration catalyst embryo body

[0033] 2 g of ammonium metavanadate, 40 g of ammonium metatungstate, 5 g of niobium oxalate and 35 ml of an aqueous oxalic acid solution with a concentration of 60% by mass were stirred and mixed at a temperature of 50° C. to obtain a mixed solution;

[0034] Put 590g of titanium dioxide, 11g of white clay, 15ml of lactic acid aqueous solution with a concentration of 50% by mass, 8g of stearic acid, 210ml of deionized water, and the mixed solution into a mixer for one-time mixing at 80°C, and after mixing for 60min Then add 30g of ceramic fiber, 20g of fluff pulp, 10g of hydroxypropyl methylcellulose, 25ml of glycerin, and 50ml of deionized water for secondary mixing, and the mud embryo is obtained after mixing for 10 minutes;

[0035] Wrap the mud embryo with plastic film, put it in a cool and humid place (the temperature is about 15 ℃) for stale treatment, and the stale time is 6h;

[...

Embodiment 3

[0038] Example 3 Preparation of honeycomb SCR flue gas denitration catalyst embryo body

[0039] 5 g of ammonium metavanadate, 20 g of ammonium metatungstate, 3 g of niobium oxalate and 30 ml of an aqueous oxalic acid solution with a concentration of 60% by mass were stirred and mixed at a temperature of 50° C. to obtain a mixed solution;

[0040] Put 525g of titanium dioxide, 30g of white clay, 12ml of lactic acid aqueous solution with a concentration of 50% by mass, 10g of stearic acid, 230ml of deionized water, and the mixed solution into a mixer and kneaded at 80°C for one time. After kneading for 55min Then add 50g of ceramic fiber, 10g of fluff pulp, 5g of hydroxypropyl methylcellulose, 20ml of glycerol, and 50ml of deionized water for secondary mixing, and the mud embryo is obtained after mixing for 15 minutes;

[0041] Wrap the mud embryo with plastic film, put it in a cool and humid place (the temperature is about 20 ℃) for stale treatment, and the stale time is 8h;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com