Dry-type paper-making method reengineering tobacco production process

A technology of reconstituted tobacco leaves and production process, which is applied in the field of dry papermaking reconstituted tobacco leaves production process, which can solve the problems of insufficient surface roughness, difficult to achieve coating rate, poor air permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, setting the finished product flake quantification as 70g / m 2 , spreading rate ≈78%, filling value ≈7.0cm 3 / g.

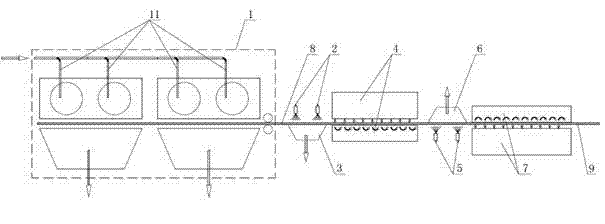

[0026] (1) Metering and crushing: The fluff pulp fiber raw material with a dryness ≥ 80% is transported to the dry air-flow sedimentation molding head 1 through the feeding air duct 11, and the fiber concentration in the feeding air duct is set to 1.5g / m 3 ;

[0027] ⑵Substrate forming: The substrate is made on the air-settling forming head 1 of the dry-laid paper machine, and the basis weight is set to 18g / m 2 , moisture 85%;

[0028] (3) One-time spraying: Spray smoke powder and glue mixture on the front of the substrate 8. When spraying, there is a negative pressure suction box 3 on the back of the substrate 8 for negative pressure vacuum suction, and the absolute dry weight of the spraying is set to 24.0g / m 2 ;

[0029] (4) One-time drying: After the first spraying, the substrate 8 is sent to the No. 1 drying oven 4 for drying until the...

Embodiment 2

[0032] Embodiment two, setting finished product sheet quantification as 110g / m 2 , spreading rate ≈64.8%, filling value ≈6.3cm 3 / g, moisture ≤12%, of which non-tobacco substances ≈32%.

[0033] (1) Metering and crushing: transport the mixture of fluff pulp fiber and tobacco fiber with a dryness ≥ 80% to the dry air sedimentation forming head 1 through the feeding air pipe 11, and set the fiber concentration in the feeding air pipe to 6g / m 3, set the mixing ratio of tobacco fiber and fluff pulp fiber mixture to 1:4 by mass percentage;

[0034] ⑵Substrate molding: The substrate is made on the air-settling forming head 1 of the dry-laid paper machine, and the basis weight is set to 40g / m 2 , moisture 85%;

[0035] (3) One-time spraying: spray smoke powder and rubber mixture on the front of the substrate 8, when spraying, there is a negative pressure suction box 3 negative pressure vacuum suction on the back of the substrate 8, and set the absolute dry weight of spraying to 31...

Embodiment 3

[0039] Embodiment three, setting finished product sheet quantification as 90g / m 2 , spreading rate ≈51%, filling value ≈6.0cm 3 / g, moisture ≤12%, of which non-tobacco substances ≈3%.

[0040] (1) Metering and crushing: transport the tobacco fiber material with a dryness ≥ 80% to the dry air-flow sedimentation forming head 1 through the feeding air pipe 11, and set the fiber concentration in the feeding air pipe to 3g / m 3 ;

[0041] ⑵Substrate molding: The substrate is made on the air-laid paper machine air-settling forming head 1, and the basis weight is set to 45g / m 2 , moisture 85%;

[0042] (3) One-time spraying: Spray smoke powder and rubber mixture on the front of the substrate 8. When spraying, there is a negative pressure suction box 3 on the back of the substrate 8 for negative pressure vacuum suction, and the absolute dry weight of the spraying is set to 20g / m 2 ;

[0043] (4) One-time drying: After the first spraying, the substrate 8 is sent to the No. 1 drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com