Disposable diaper

a disposable diaper and diaper technology, applied in the field of disposable diapers, can solve the problems of reducing distribution efficiency, reducing the efficiency of distribution, and reducing the number of diaper packages, so as to achieve excellent leakproofness, light and compact, convenient to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

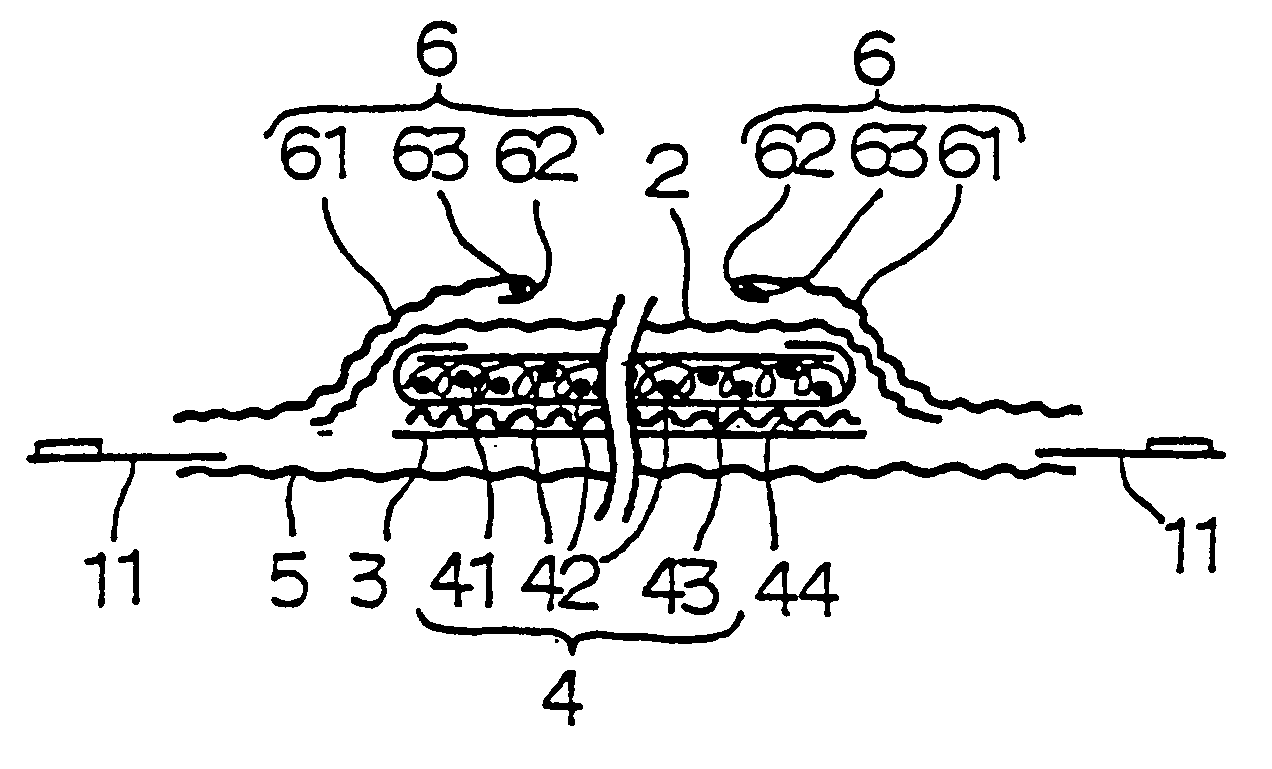

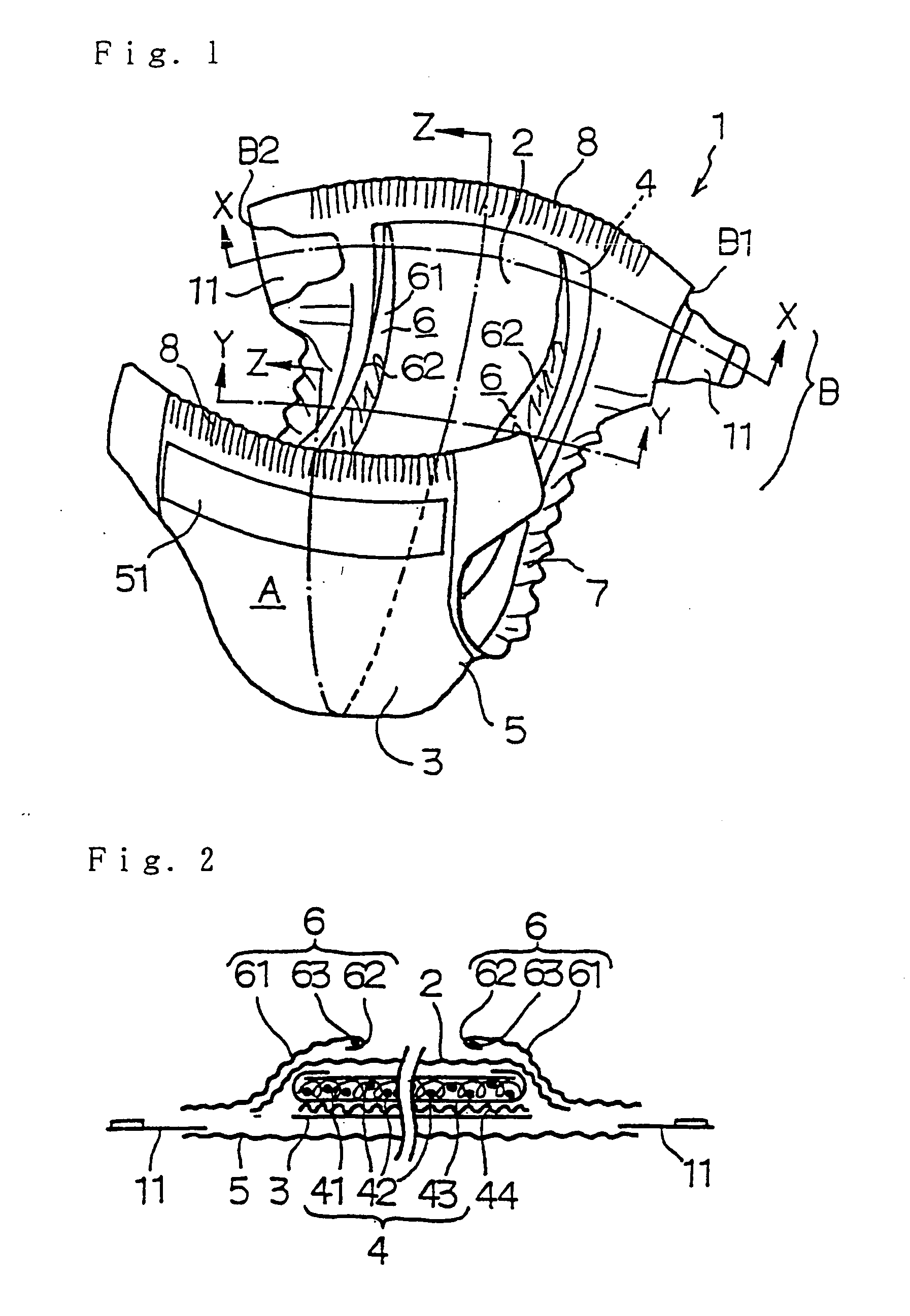

example 1

[0097] A superabsorbent polymer A having a rate of absorption of 11.8 g / 30 sec / 0.3 g by the DW method (10SH-P (trade name), available from Sumitomo Seika Chemicals Co., Ltd.) and a superabsorbent polymer B having a rate of absorption of 3.6 g / 30 sec / 0.3 g by the DW method (CA-W4 (trade name), available from Nippon Shokubai Co., Ltd.) were mixed at a polymer A / polymer B weight ratio of 50 / 50 to prepare a mixed superabsorbent polymer. PP / PE core / sheath conjugate fiber and PET fiber were mixed at a weight ratio of 70 / 30 and fabricated into airthrough nonwoven fabric having a basis weight of 30 g / m2. The mixed superabsorbent polymer was scattered on the nonwoven fabric in an amount of 200 g / m2 to be held in the interstices of the fibers. A tissue having a basis weight of 15 g / m2 was wrapped about the nonwoven fabric having the polymers held therein to make an absorbent member.

[0098] A PP / PE nonwoven fabric was put on one side of the absorbent member as a topsheet, and on the other side...

example 2

[0099] A hot-melt adhesive was applied to a tissue, and the mixed superabsorbent polymer prepared in the same manner as in Example 1 was scattered thereon in an amount of 200 g / m2. Another tissue having a hot-melt adhesive applied thereto was superposed thereon to make an absorbent member. A disposable diaper was obtained by using the resulting absorbent member in the same manner as in Example 1.

example 3

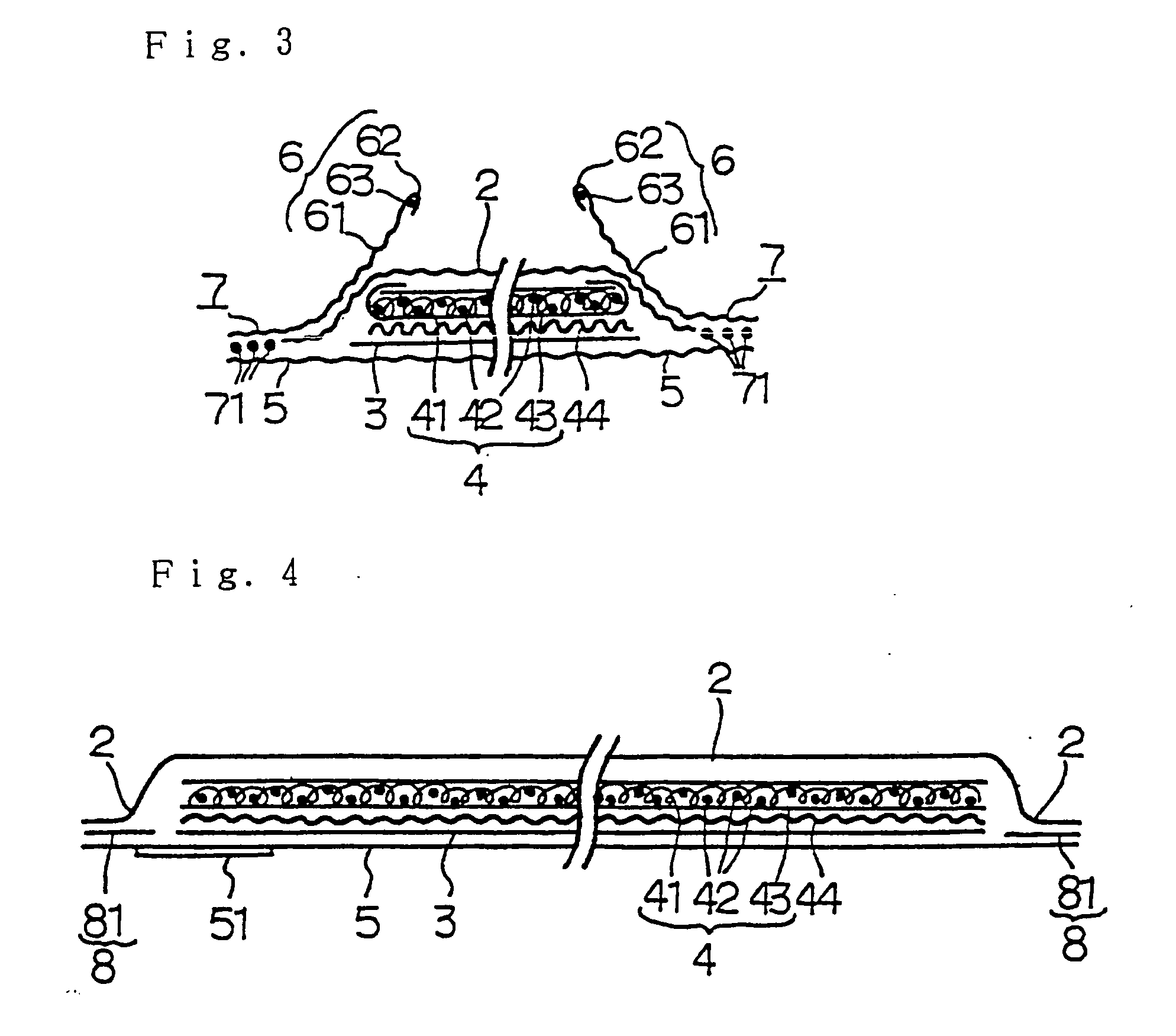

[0110] The superabsorbent polymers A and B used in Example 1 were mixed at a polymer A / polymer B weight ratio of 30 / 70 to prepare a mixed superabsorbent polymer.

[0111] The mixed superabsorbent polymer, fluff pulp and heat-fusible PP / PE core / sheath conjugate fiber were mixed up at a weight ratio of 85 / 10 / 5 and built up into a sheeting having 200 g / m2 of the mixed superabsorbent polymer, 24 g / m2 of fluff pulp, and 12 g / m2 of the heat-fusible conjugate fiber. The resulting fiber aggregate was wrapped in a tissue having a basis weight of 15 g / m2 and subjected to a heat treatment to make an absorbent member having a fluff content of 9% by weight.

[0112] A medium size disposable diaper for babies having the form of FIG. 1 was prepared in the same manner as in Example 1, except for using the above prepared absorbent member.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com