Trash bag for wet trash

a technology for wet trash and trash bags, applied in the field of plastic trash bags, can solve the problems of high cost, frequent leakage of fluids out of bags, and public health hazards, and achieve the effect of low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

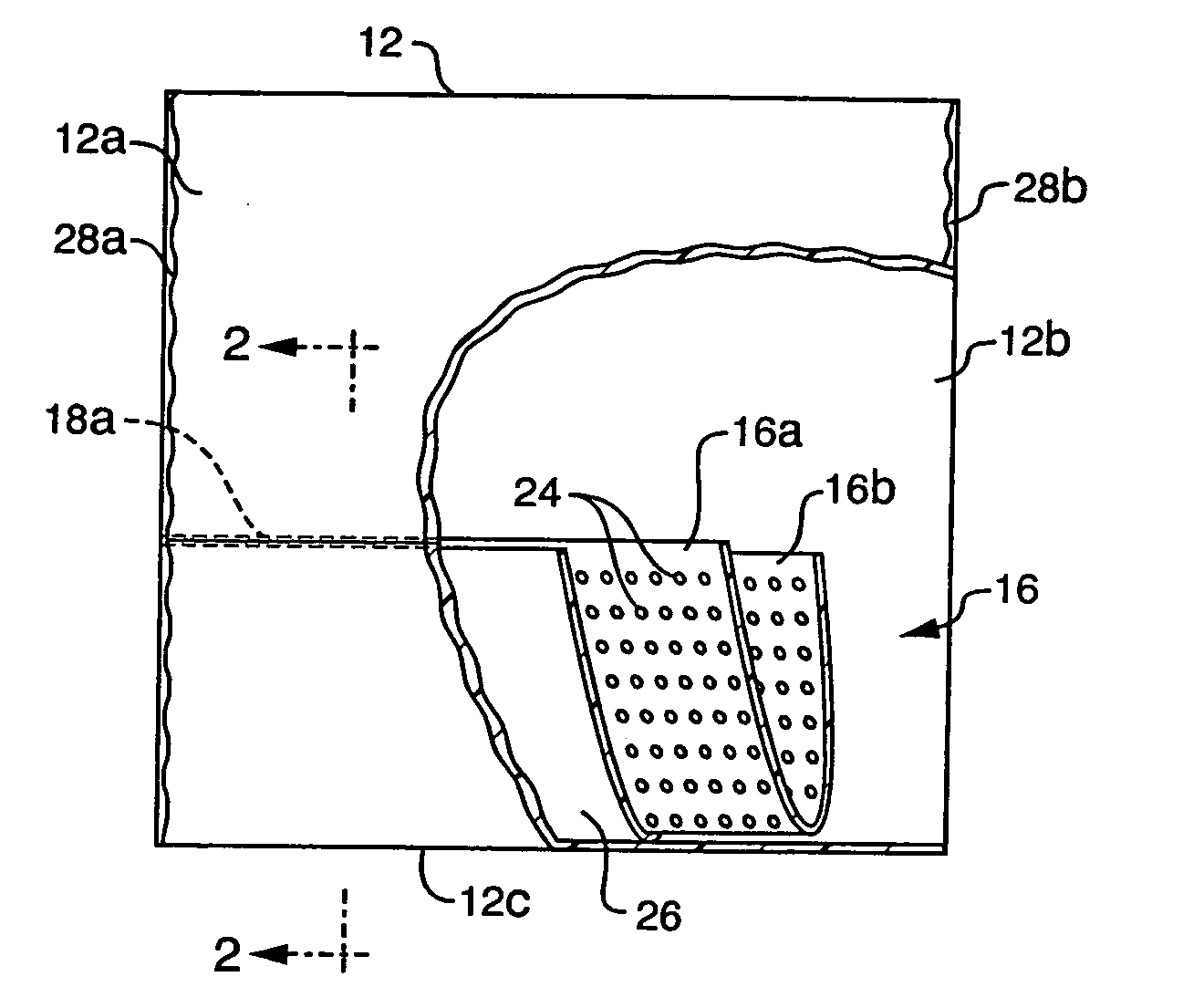

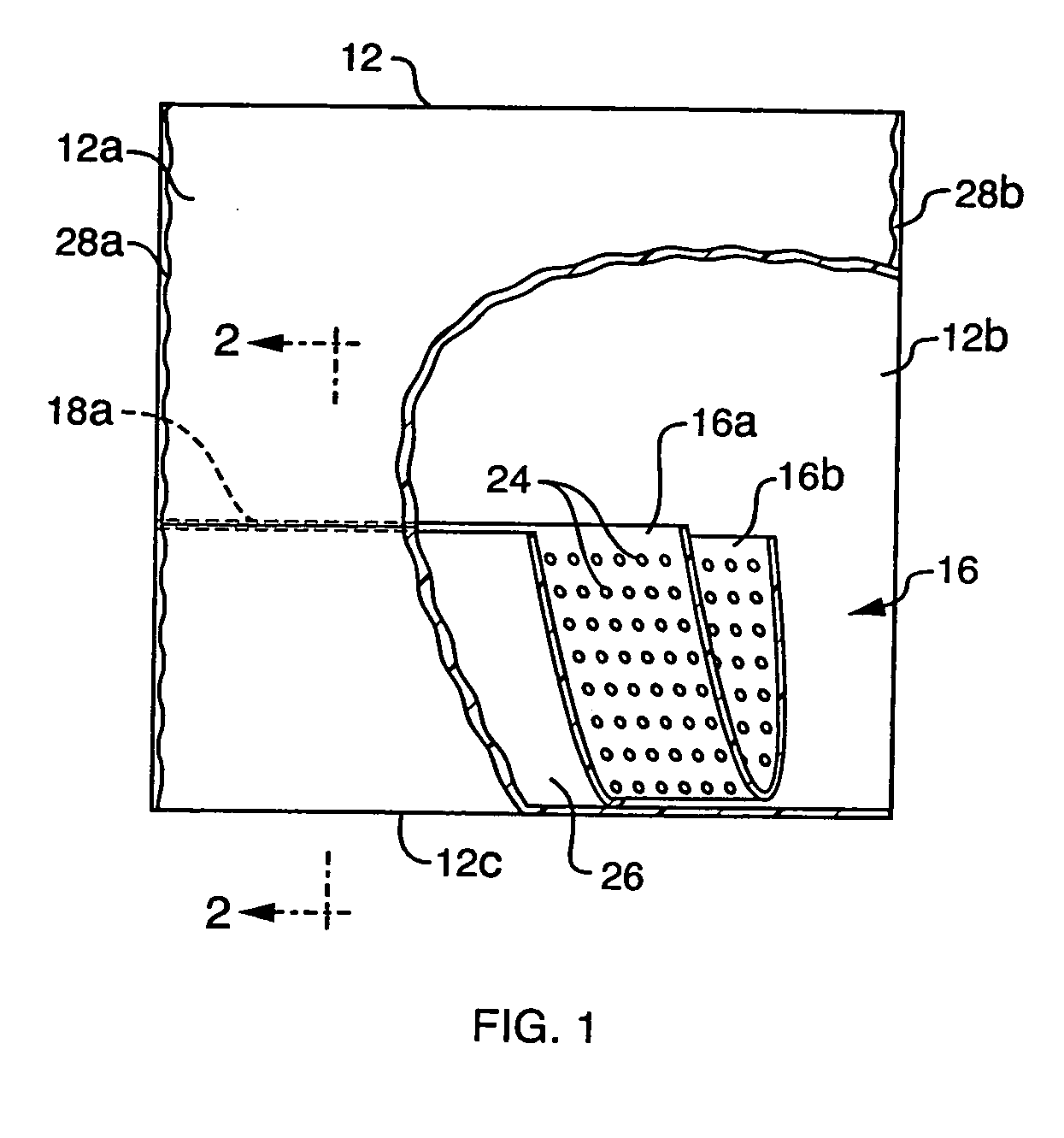

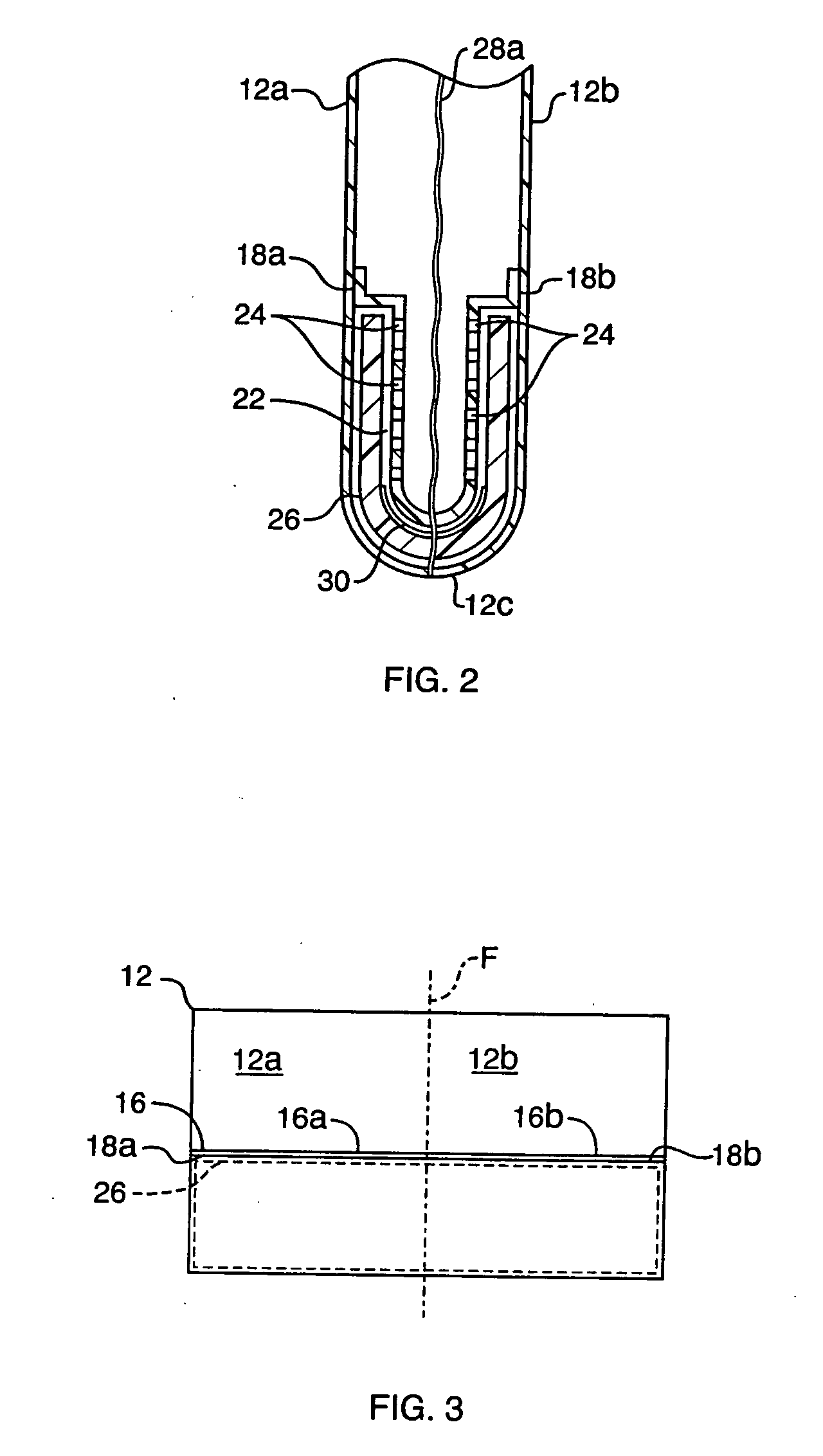

[0019] Referring to FIGS. 1 and 2 of the drawings, the subject bag comprises an outer ply or layer 12 of a flexible fluid impervious sheet material. Layer 12 includes a front wall 12a and a rear wall 12b which are formed by folding the sheet material at a fold line 12c at the bottom of the bag. The ply or layer 12 is preferably made of a plastic sheet material such as polyethylene, polypropylene or the like. Depending upon the desired bag strength, the ply 12 may have a thickness of 0.5 to 1.5 mils for example.

[0020] The bag also includes an inner ply or layer 16 of a flexible sheet material. Like ply 12, ply 16 is folded to form front and rear walls 16a and 16b and the upper edges of those walls are secured to walls 12a and 12b by transverse bonded or welded seams 18a and 18b to define a compartment 22 between the two plies 12 and 16, respectively. 5 While the inner ply walls 16a and 16b are shown as extending about a third of the way up from the bottom of the bag, it should be un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com