Ceramics injection moulding automatic molding equipment

An automatic forming and hot die casting technology, applied in the field of ceramic machinery, can solve the problems of insufficient smoothness, incision, continuous operation for a long time, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A ceramic hot die-casting automatic molding device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

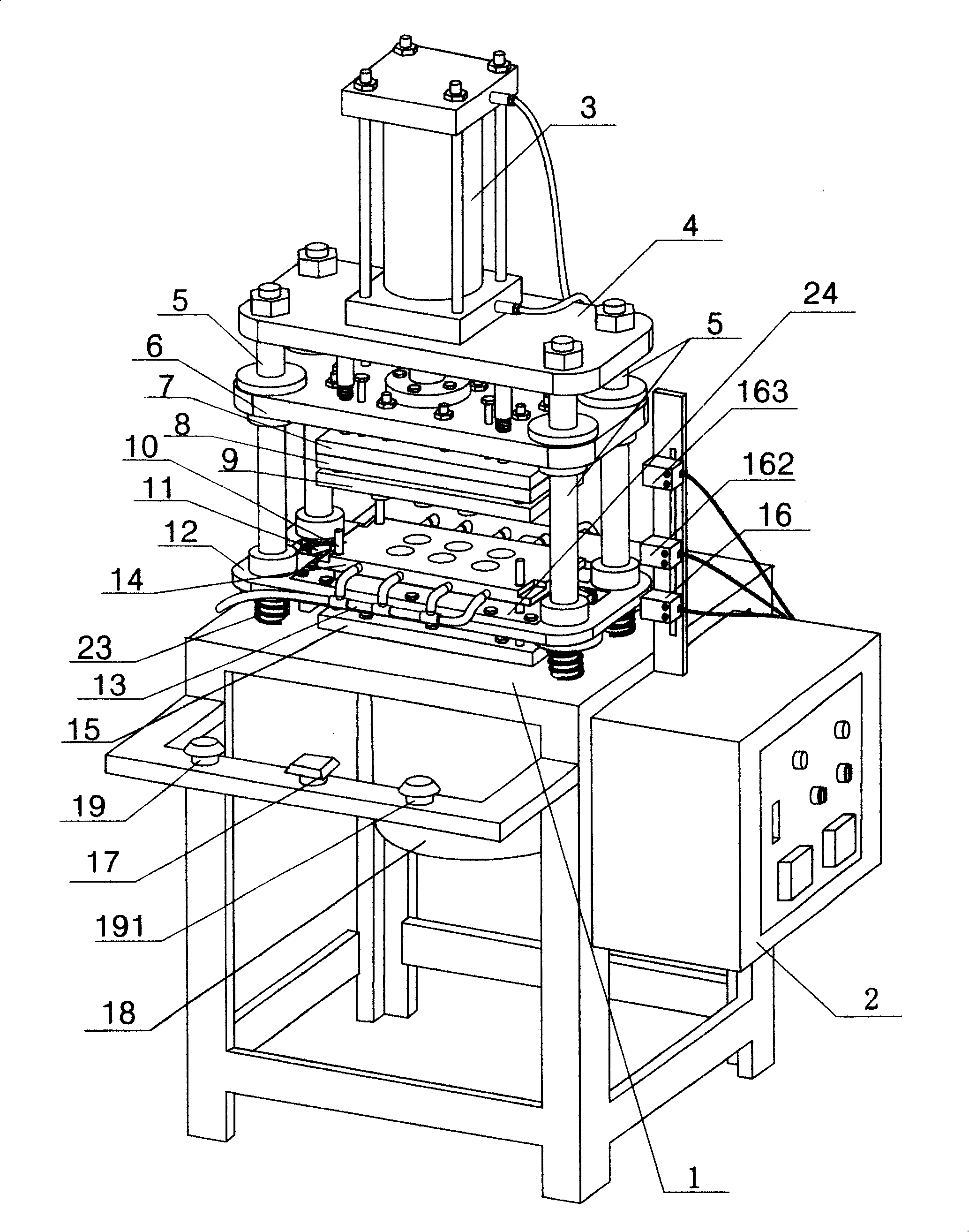

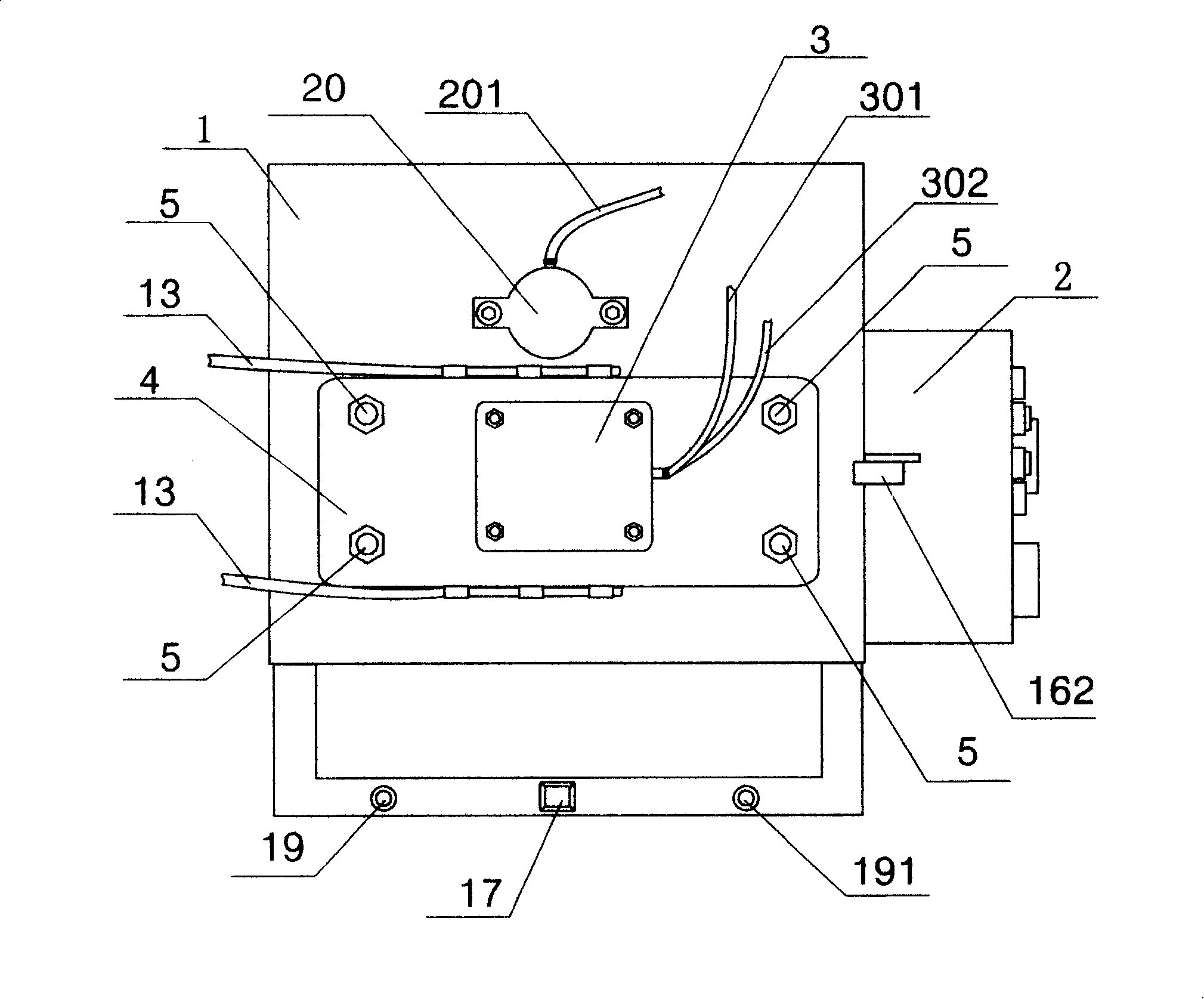

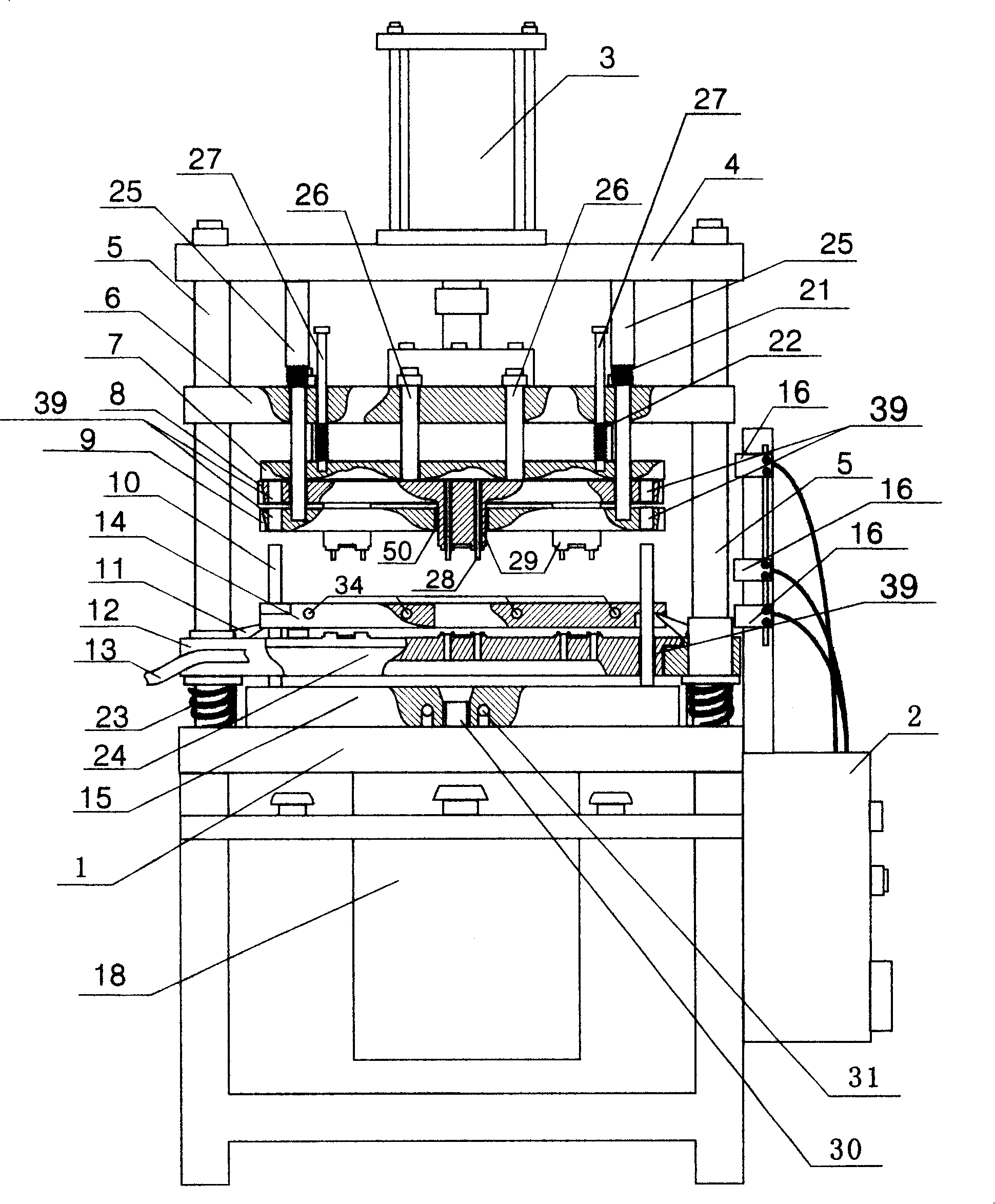

[0028] refer to figure 1 , figure 2 , image 3 , figure 1 It is a three-dimensional structure diagram of a ceramic hot die-casting automatic molding device according to the present invention, figure 2 It is a top view of a ceramic hot die-casting automatic molding device according to the present invention, image 3It is a partial cross-sectional view of a ceramic hot die-casting automatic molding device according to the present invention. As shown in these three drawings, four guide posts 5 are connected to the upper surface of the machine base plate 1, and the lower ends of these four guide posts are covered with Die-pushing spring 23, lower guide plate 12, upper guide plate 6 also slide sleeve on these four guide pillars, the top of guide pillar fixes a top plate 4 with screw, and a cylinder 3 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com