Metal plate material hydraulic shaping method and its mould device

A technology of hydroforming and sheet metal, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems that the rigid punch cannot enter the concave die, the mold and welding device are complex, and cannot be integrally formed at one time, so as to achieve enhanced new Product development capabilities, significant economic benefits, and ingenious design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

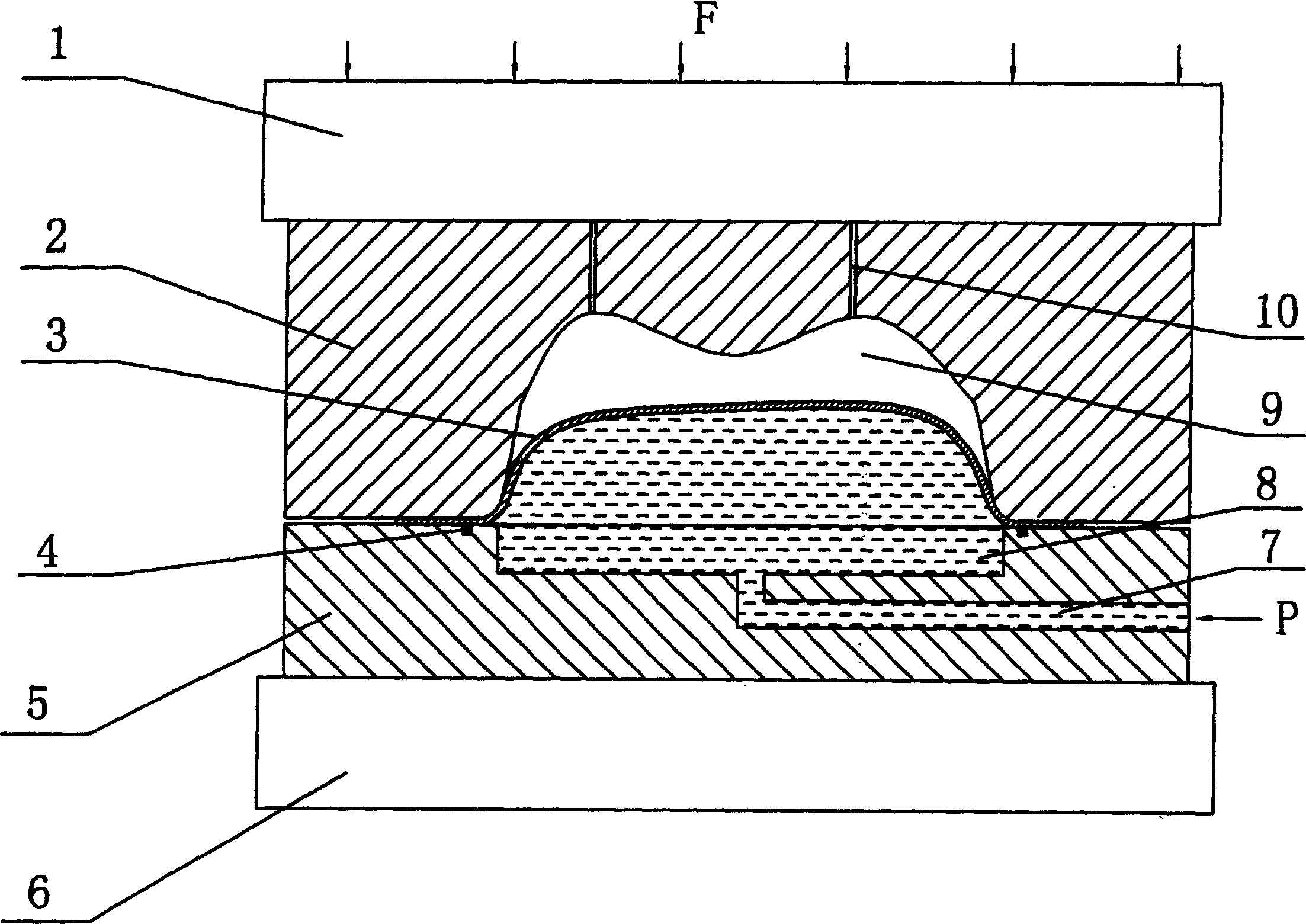

[0021] The hydroforming method of sheet metal of the present invention comprises the steps:

[0022] 1) First fill the hydraulic chamber (8) with hydraulic oil;

[0023] 2) placing the sheet material (3) to be formed between the hydraulic chamber (8) and the die (2);

[0024] 3) die (2) descends;

[0025] 4) Apply blank-holding and clamping force F to the sheet (3) and die (2);

[0026] 5) The high-pressure liquid with a filling pressure of P makes the sheet material to be deep-drawn and deformed under the action of the high-pressure liquid, and it is formed into the shape of the required part close to the surface of the concave mold cavity.

[0027] The structure diagram of hydroforming mold device of the present invention is as figure 1 Shown, comprise upper formwork (1), die (2), hydraulic pressure plate (5), make on the die (2) have the concave mold cavity (9) that is consistent with the part shape to be formed, hydraulic pressure plate (5) ) is made with a hydraulic c...

Embodiment 2

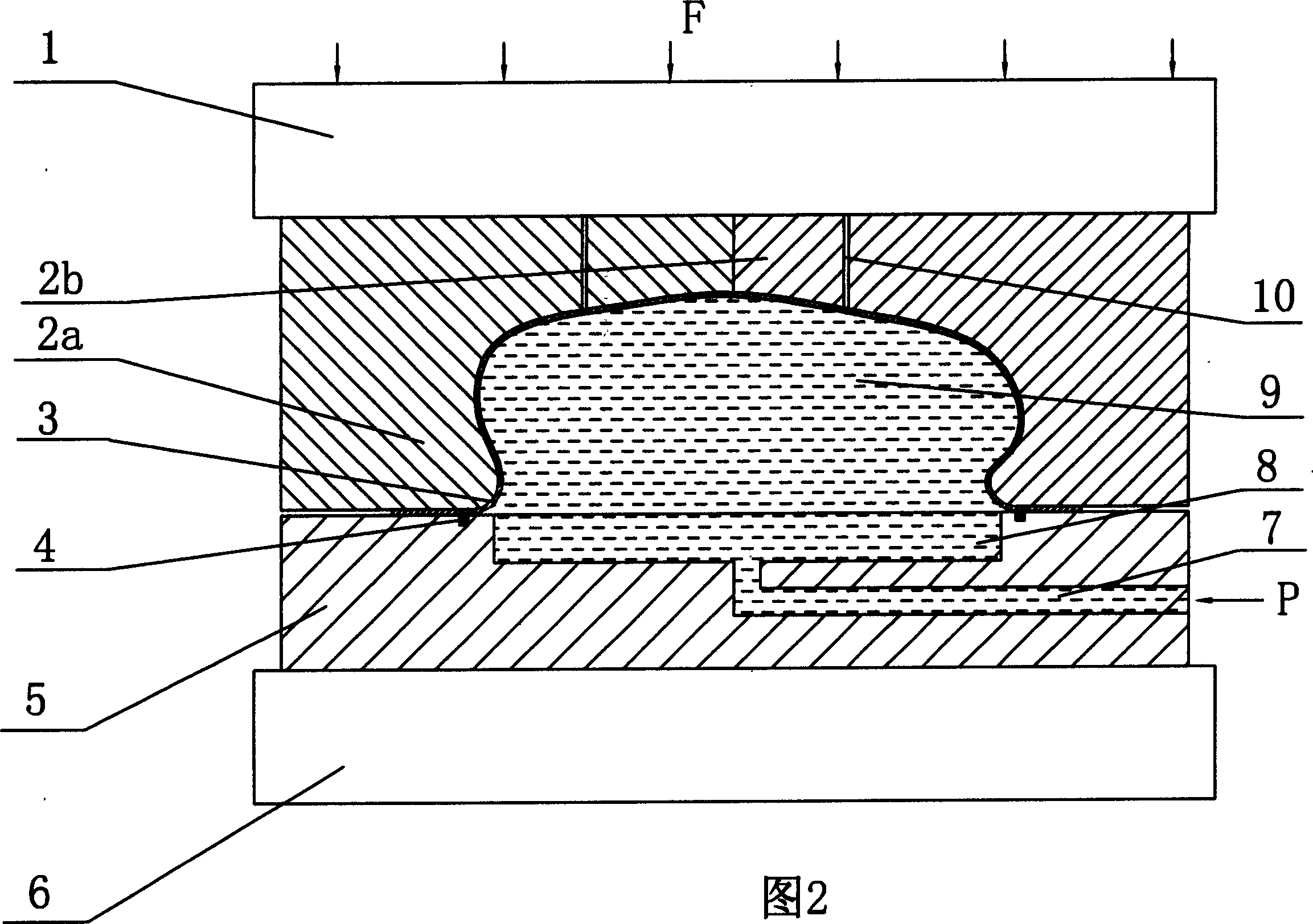

[0033] The hydroforming method of the sheet metal of the present invention is the same as that of Embodiment 1. The structure schematic diagram of hydroforming mold device of the present invention is as shown in Figure 2, and its structure is identical with embodiment 1, and difference is that die (2) is used for forming the part of band necking, and is made on die (2) The position of necking, for this reason, die (2) is made to comprise the insert body die (2a, 2b) that can separate left and right.

[0034] The processing of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com