Smashing, compressing and moulding equipment for fruit and vegetable garbage and moulding method thereof

A compression molding and waste technology, applied in the field of environmental sanitation equipment, can solve the problems of waste, landfill reduction, expensive transportation and treatment costs, etc., and achieve the effect of saving storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

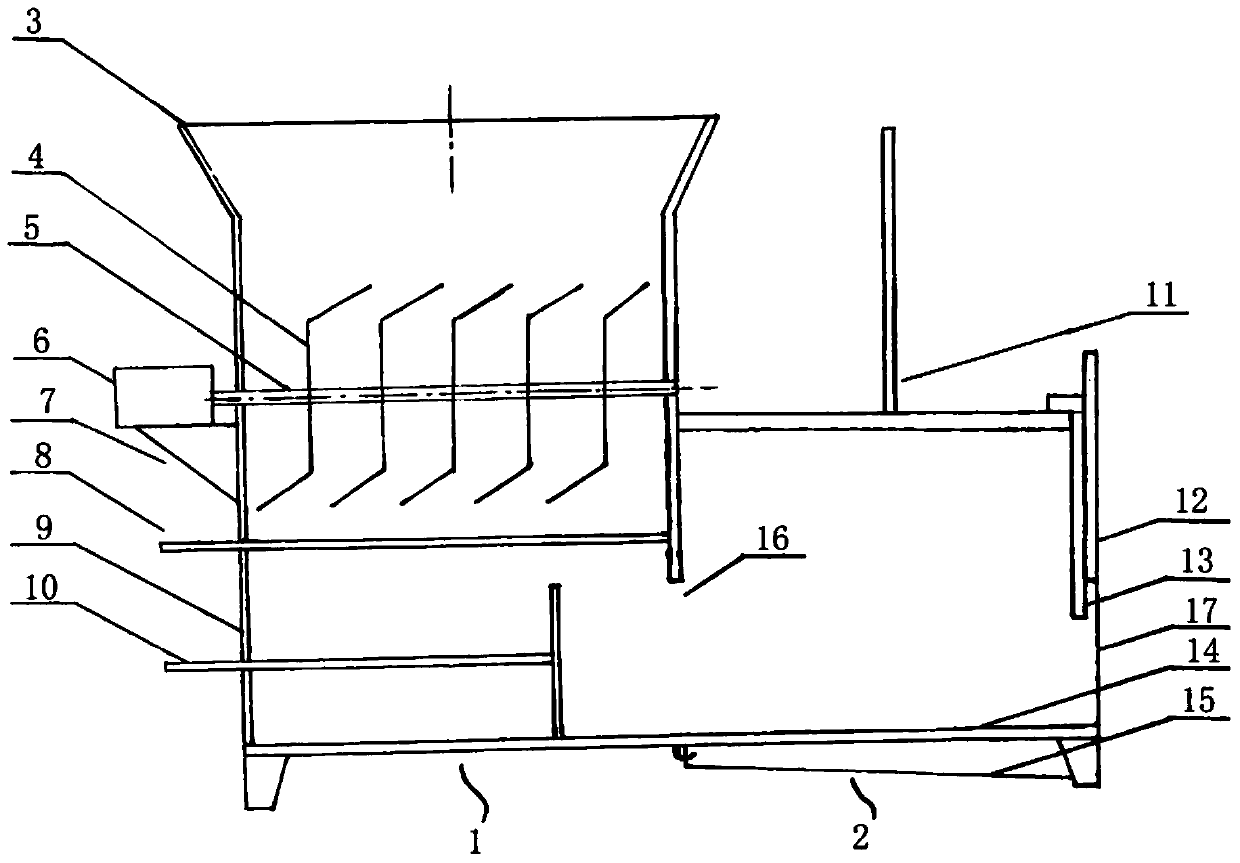

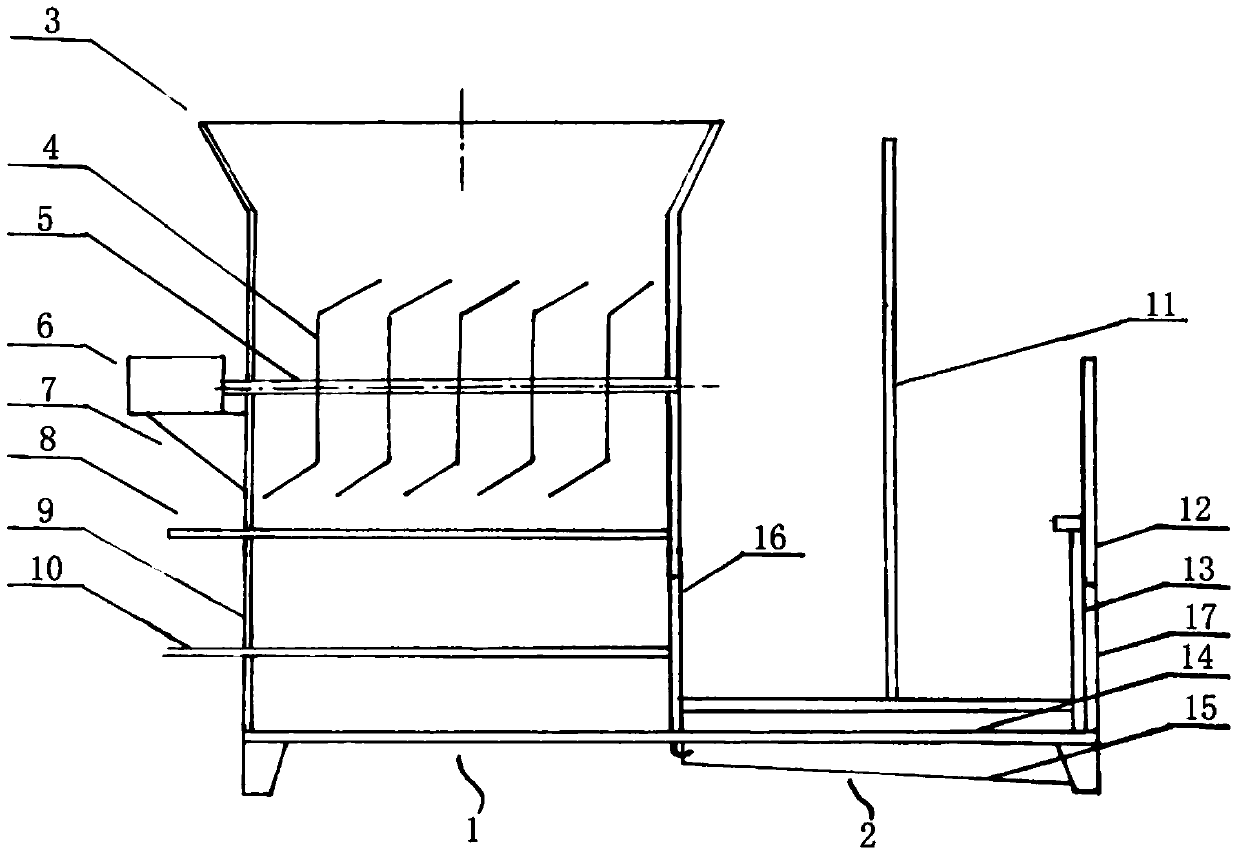

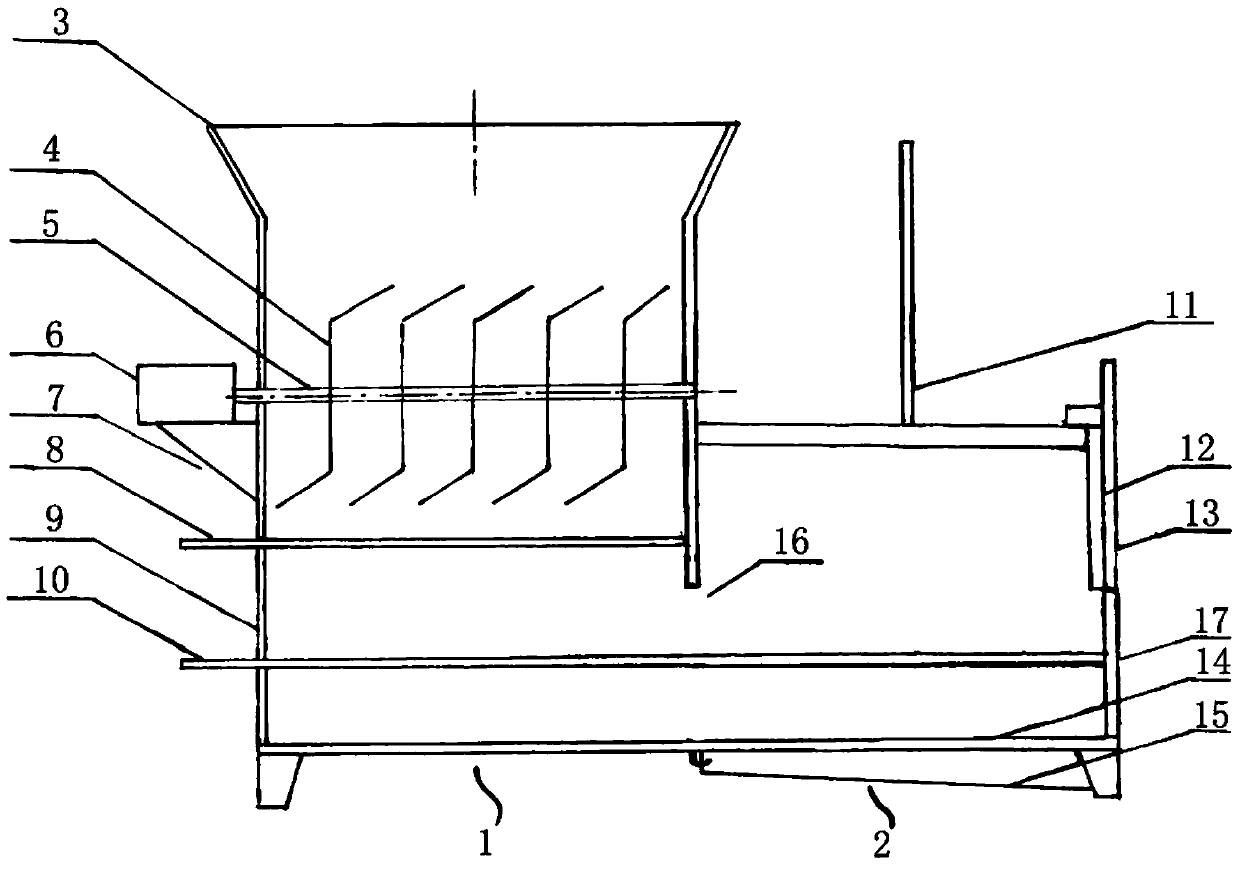

[0046] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

[0047] refer to figure 1 , figure 2 , image 3 , a crushing and compression molding equipment for fruit and vegetable waste, comprising a cutting and crushing device 1 and a compression molding device 2 . The cutting and crushing device 1 includes a crushing inlet 3 and a crushing chamber connected to the crushing inlet 3. After the main shaft 5 passes through the crushing chamber, it is connected to the power mechanism 6 outside the crushing chamber. A support frame 7 is arranged outside the crushing chamber, and the power mechanism 6 Place it on the support frame 7.

[0048] The main shaft 5 is provided with a flying knife group 4, refer to Figure 4 , Figure 5 , The flying knife group 4 includes at least two flying knives 41 for crushing mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com