Forming device and method of aluminum-based silicon carbide particle reinforced composite material and member thereof

An aluminum-based silicon carbide and forming device technology, which is applied in the field of forming metal matrix composite materials, can solve the problems of loose internal structure, complex forming process, and difficult processing, and achieve dense and uniform internal structure, simple forming process and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

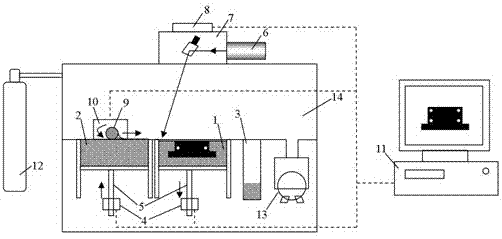

[0027] The method for manufacturing aluminum-based silicon carbide particle-reinforced composite materials and components thereof based on the molding device described in Example 1, is characterized in that the method includes the following steps:

[0028] (1) Mix aluminum alloy powder with an average particle size of 0.05mm and W10 brand silicon carbide powder (equivalent particle size less than 0.05mm) in a volume ratio of 60%: 40%;

[0029] (2) Put the mixed powder into the powder feeding cylinder of the molding device;

[0030] (3) Input the three-dimensional digital model of the aluminum-based silicon carbide particle-reinforced composite material or its components into the control system of the molding device; the format of the three-dimensional digital model is STL format;

[0031] (4) Use the control system of the molding device to control the laser system, powder spreading system, powder feeding cylinder and bottom plate of the forming cylinder. According to the input...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com