Modularized cold runner system

A technology of cold runner and fixed mold, which is applied in the field of cold runner injection molding molds, can solve the problems of frequent cleaning of molds, unbalanced mold thermal layout, long mold production cycle, etc., to shorten the product injection molding cycle, reduce Raw material waste and injection pressure and clamping force, effects of avoiding trimming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

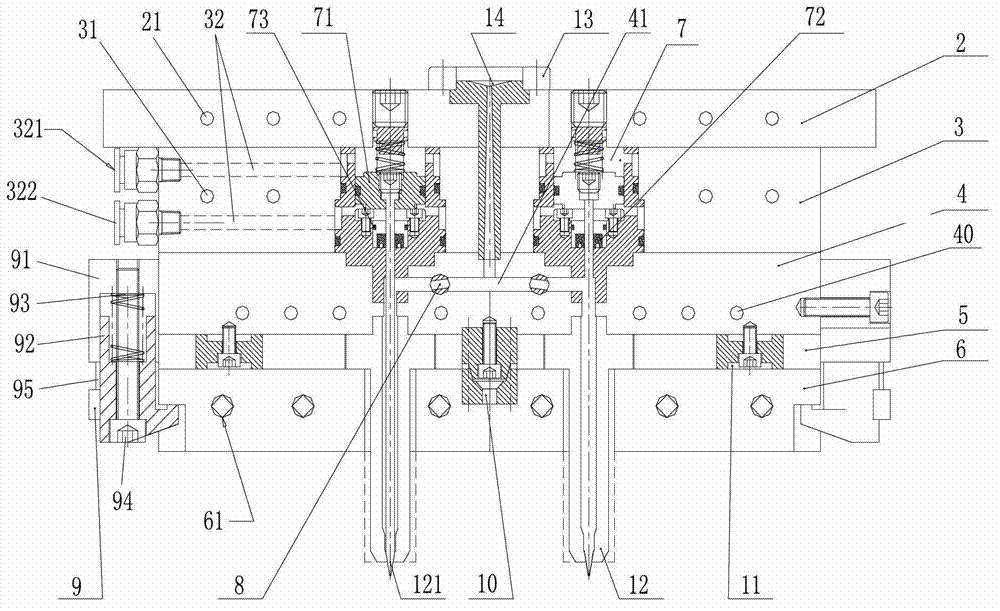

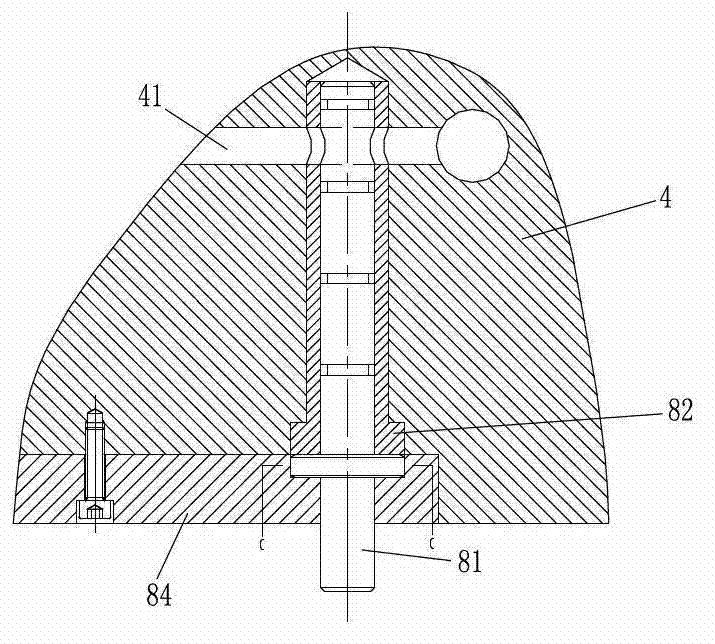

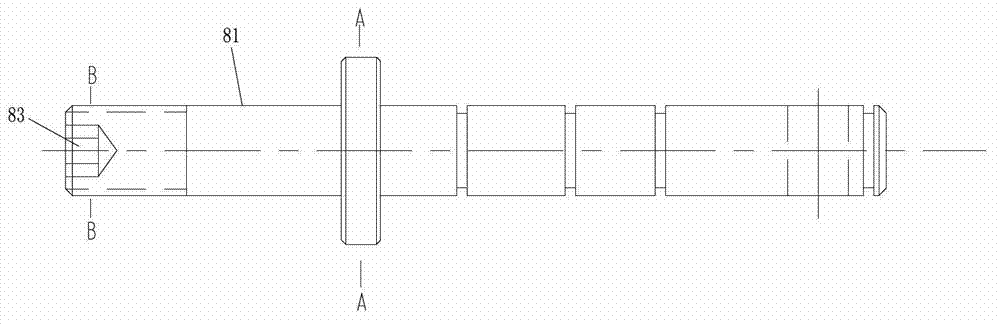

[0030] see figure 1 , the present invention is sequentially provided with a fixed mold base plate 2, a cylinder mounting plate 3, a cold runner plate 4, a heat insulation plate 5, a heating plate 6, a cylinder 7, a fluid modulation device 8, a taper positioning block 10, and a bearing Briquetting block 11 (there are several), water-cooled needle valve nozzle 12 and quick-change fixture 9 etc.

[0031]The fixed mold seat plate 2 is connected with the external frame through a pressing plate. The upper end of the fixed mold base plate 2 is provided with a positioning ring 13, and the fixed mold base plate 2 is provided with a sprue sleeve 14. The sprue sleeve 14 passes through the fixed mold base plate 2 and the cylinder mounting plate 3, and the upper end of the sprue sleeve 14 and the positioning ring Corresponding to 13, the lower end of the sprue sleeve 14 extends into the cold runner plate 4, and the sprue sleeve 14 is provided with a sprue 141. The end of the main channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com