Releasing method and releasing apparatus of work having adhesive tape

a technology of releasing method and releasing apparatus, which is applied in the direction of mechanical apparatus, sleeve/socket joint, layered products, etc., can solve the problems of deformation of dicing adhesive tape, cracking or damage of semiconductor wafers, and delay in releas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

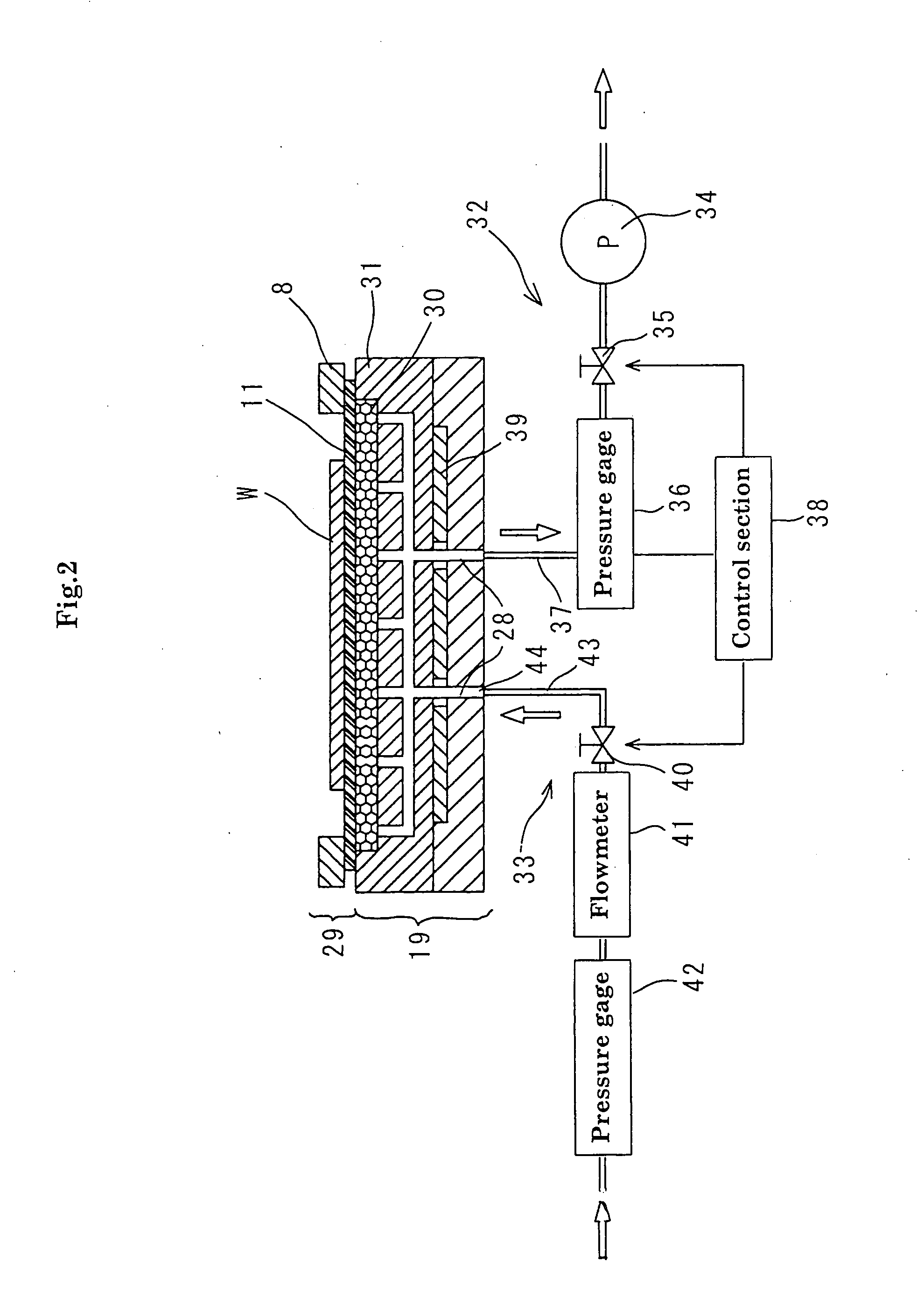

[0036] An example of embodiments of the present invention will be explained with reference to the drawings.

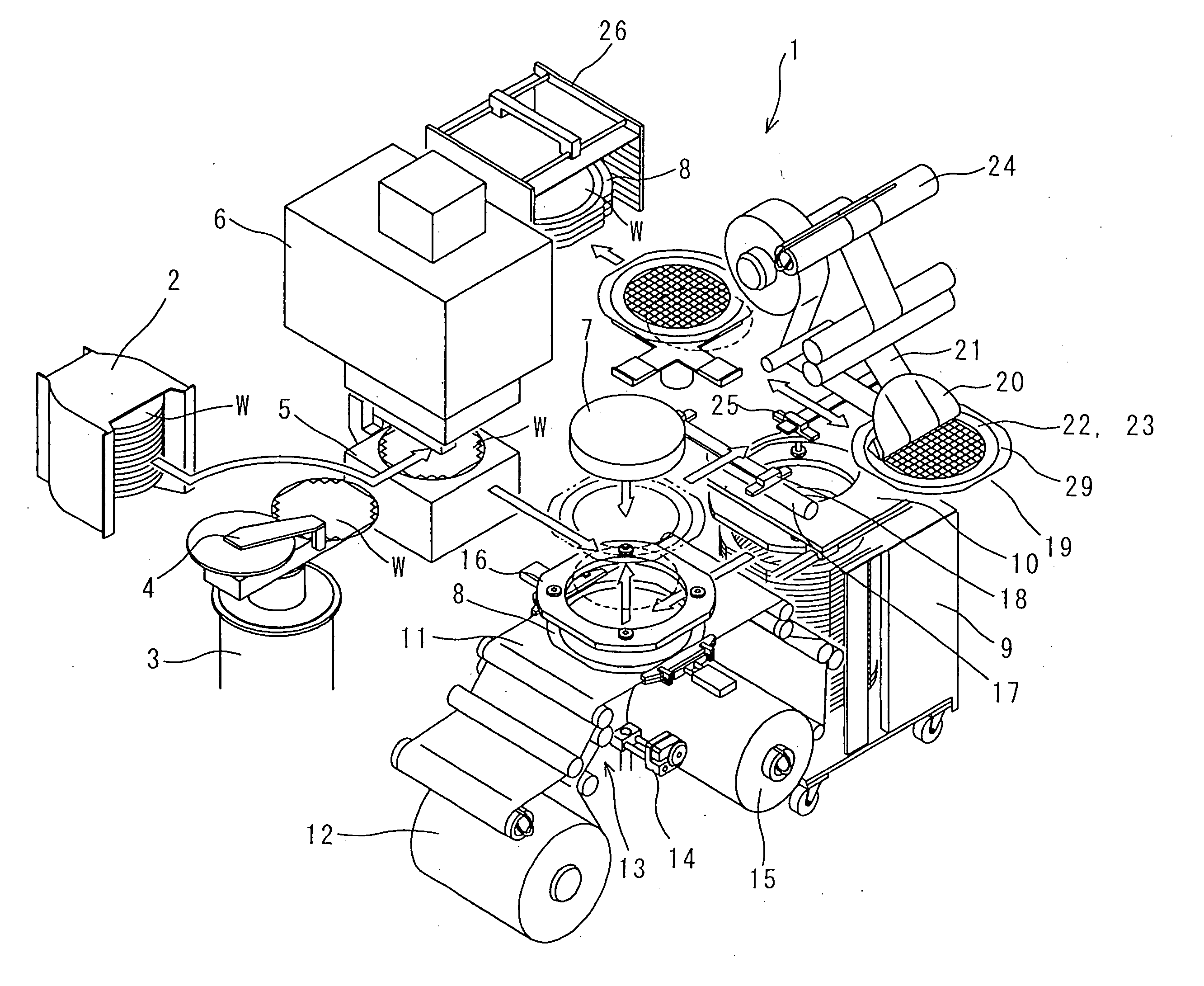

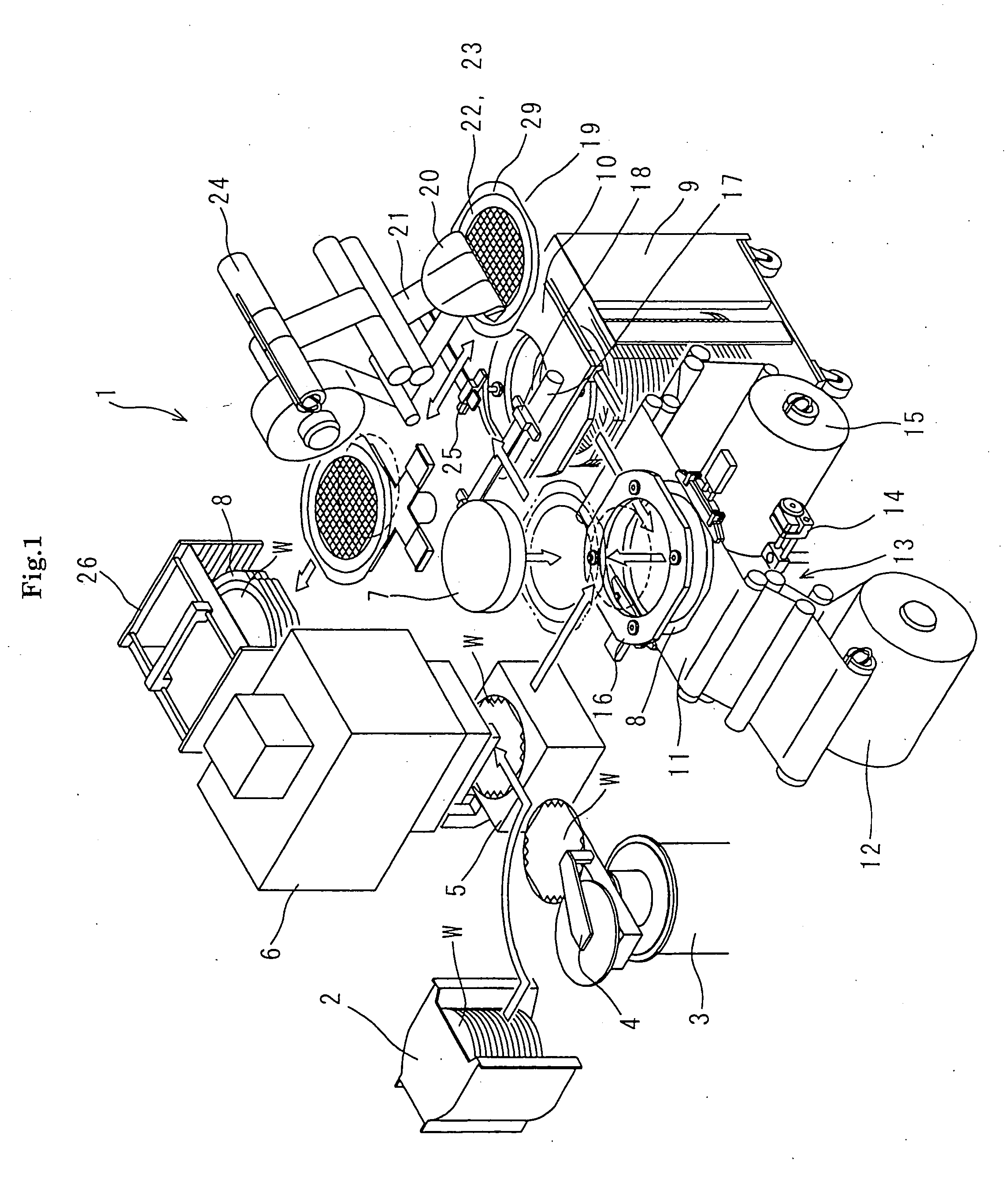

[0037]FIG. 1 is a schematic perspective view showing an essential portion of one example of a semiconductor wafer mount apparatus having one example of embodiments of a releasing apparatus of a work having an adhesive tape according to the present invention.

[0038] As shown in FIG. 1, a semiconductor wafer mount apparatus 1 of the embodiment includes a wafer supply section 2 to which a cassette. A plurality of layers of semiconductor wafers (wafers, hereinafter) W subjected to the back grind process are accommodated in the cassette. The semiconductor wafer mount apparatus 1 also includes a wafer transport mechanism 3 having a robot arm which bends and turns, a wafer pressing mechanism 4 which corrects a warped wafer into a flat surface, an alignment stage 5 which carries out the positioning, an ultraviolet rays irradiation unit 6 for irradiating the surface protecting tape wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com