Method for preparing calcium carbide

A technology of calcium carbide and quicklime, applied in the direction of carbide, calcium carbide, etc., can solve the problems of high pollution and high energy consumption of calcium carbide production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

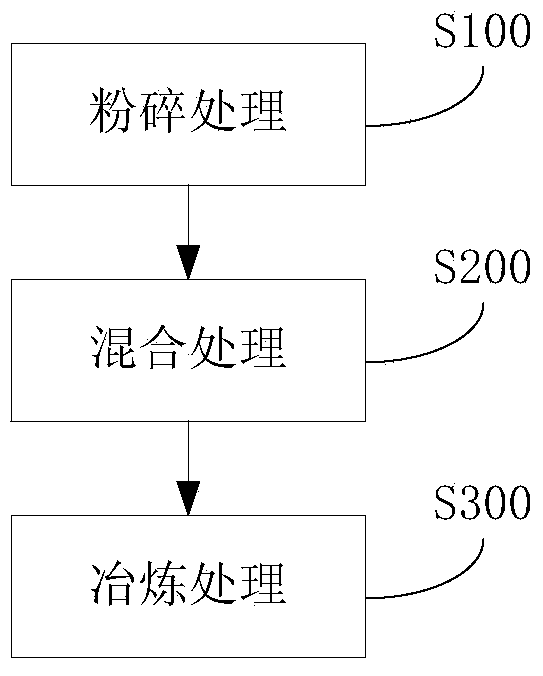

[0035] The method for preparing calcium carbide according to the embodiment of the present invention prepares and pulverizes carbon-based raw materials and calcium-based raw materials, for example, pulverizes to an ultrafine powder with an average particle size of not more than 20 microns, and significantly increases the carbon-based raw materials and calcium-based raw materials after mixing. The contact area can significantly reduce the reaction temperature and speed up the reaction rate. Compared with the traditional method for preparing calcium carbide, the method significantly reduces energy consumption. According to a specific embodiment of the present invention, preferably, carbon-based raw materials and calcium-based raw materials can be crushed to an average particle size of less than 10 microns, and then the smelting treatment can be carried out at 1600-1800 degrees Celsius for 10-20 minutes to prepare calcium carbide. According to a specific embodiment of the present...

Embodiment

[0043] Using semi-coke with a fixed carbon content of 82.86% as the carbon-based raw material and quicklime with a calcium oxide content of 92% as the calcium-based raw material, the semi-coke is first dried to obtain a semi-coke with a moisture content of less than 5%, and then The dried semi-coke and quicklime are respectively crushed to less than 2 mm, and then crushed to 10 microns; the obtained semi-coke particles and quicklime particles are mixed according to a mass ratio of 1:1.8 to obtain a mixed material; the obtained The mixed material is processed in a gas melting furnace at 1680 degrees Celsius for 10 to 20 minutes to obtain molten calcium carbide, which is discharged in liquid form through the bottom of the furnace, cooled and crushed to obtain calcium carbide products.

[0044] According to the method for preparing calcium carbide in the above embodiment, the content of calcium carbide in the prepared calcium carbide can reach 78.57%, the gas generation can reach ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com