Insulated thermal conductive adhesive and preparation method thereof

A technology of insulation, heat conduction and adhesive, applied in the direction of adhesive types, non-polymer adhesive additives, adhesives, etc., can solve the problems of unsatisfactory and single insulation, heat conduction and adhesion, and achieve the filling effect. Good, strong agglomeration tendency, the effect of reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

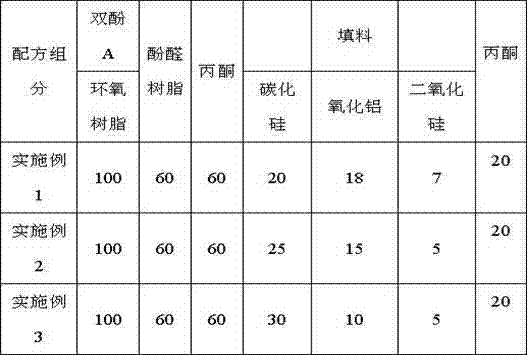

Embodiment 1

[0024] (1) Prepare adhesive matrix glue. In terms of parts by mass, 100 parts of bisphenol A epoxy resin and 60 parts of phenolic resin were weighed and dissolved in 60 parts of acetone. Place it on a strong magnetic stirrer and stir until it is evenly mixed to obtain an adhesive matrix glue solution for use.

[0025] (2) Prepare a nano-inorganic composite filler solution. In parts by mass, 25 parts of nano-scale silicon carbide, 15 parts of nano-scale alumina, and 5 parts of nano-scale silicon dioxide were weighed and dissolved in 20 parts of acetone. Place it on a strong magnetic stirrer and stir until it is evenly mixed to obtain a nano-inorganic composite filler solution, which is ready for use.

[0026] (3) Add the nano-inorganic composite filler solution prepared above into the adhesive matrix glue, place it on a strong magnetic stirrer, and stir until it is evenly mixed, and then an insulating thermally conductive adhesive for high thermal conductivity aluminum-b...

Embodiment 2

[0028] (1) Prepare adhesive matrix glue. In terms of parts by mass, 100 parts of bisphenol A epoxy resin and 60 parts of phenolic resin were weighed and dissolved in 60 parts of acetone. Place it on a strong magnetic stirrer and stir until it is evenly mixed to obtain an adhesive matrix glue solution for use.

[0029] (2) Prepare a nano-inorganic composite filler solution. In terms of parts by mass, 20 parts of nano-scale silicon carbide, 18 parts of nano-scale alumina, and 7 parts of nano-scale silicon dioxide were weighed and dissolved in 20 parts of acetone. Place it on a strong magnetic stirrer and stir until it is evenly mixed to obtain a nano-inorganic composite filler solution, which is ready for use.

[0030] (3) Add the nano-inorganic composite filler solution prepared above into the adhesive matrix glue, place it on a strong magnetic stirrer, and stir until it is evenly mixed, and then an insulating thermally conductive adhesive for high thermal conductivity a...

Embodiment 3

[0032] (1) Prepare adhesive matrix glue. In terms of parts by mass, 100 parts of bisphenol A epoxy resin and 60 parts of phenolic resin were weighed and dissolved in 60 parts of acetone. Place it on a strong magnetic stirrer and stir until it is evenly mixed to obtain an adhesive matrix glue solution for use.

[0033] (2) Prepare a nano-inorganic composite filler solution. In terms of parts by mass, 30 parts of nano-scale silicon carbide, 10 parts of nano-scale alumina, and 5 parts of nano-scale silicon dioxide were weighed and dissolved in 20 parts of acetone. Place it on a strong magnetic stirrer and stir until it is evenly mixed to obtain a nano-inorganic composite filler solution, which is ready for use.

[0034] (3) Add the nano-inorganic composite filler solution prepared above into the adhesive matrix glue, place it on a strong magnetic stirrer, and stir until it is evenly mixed, and then an insulating thermally conductive adhesive for high thermal conductivity alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com