Inserting type stud assembly and disassembly clamp

A double-ended stud, plug-in technology, applied in the direction of hand-held tools, manufacturing tools, workpiece clamping devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

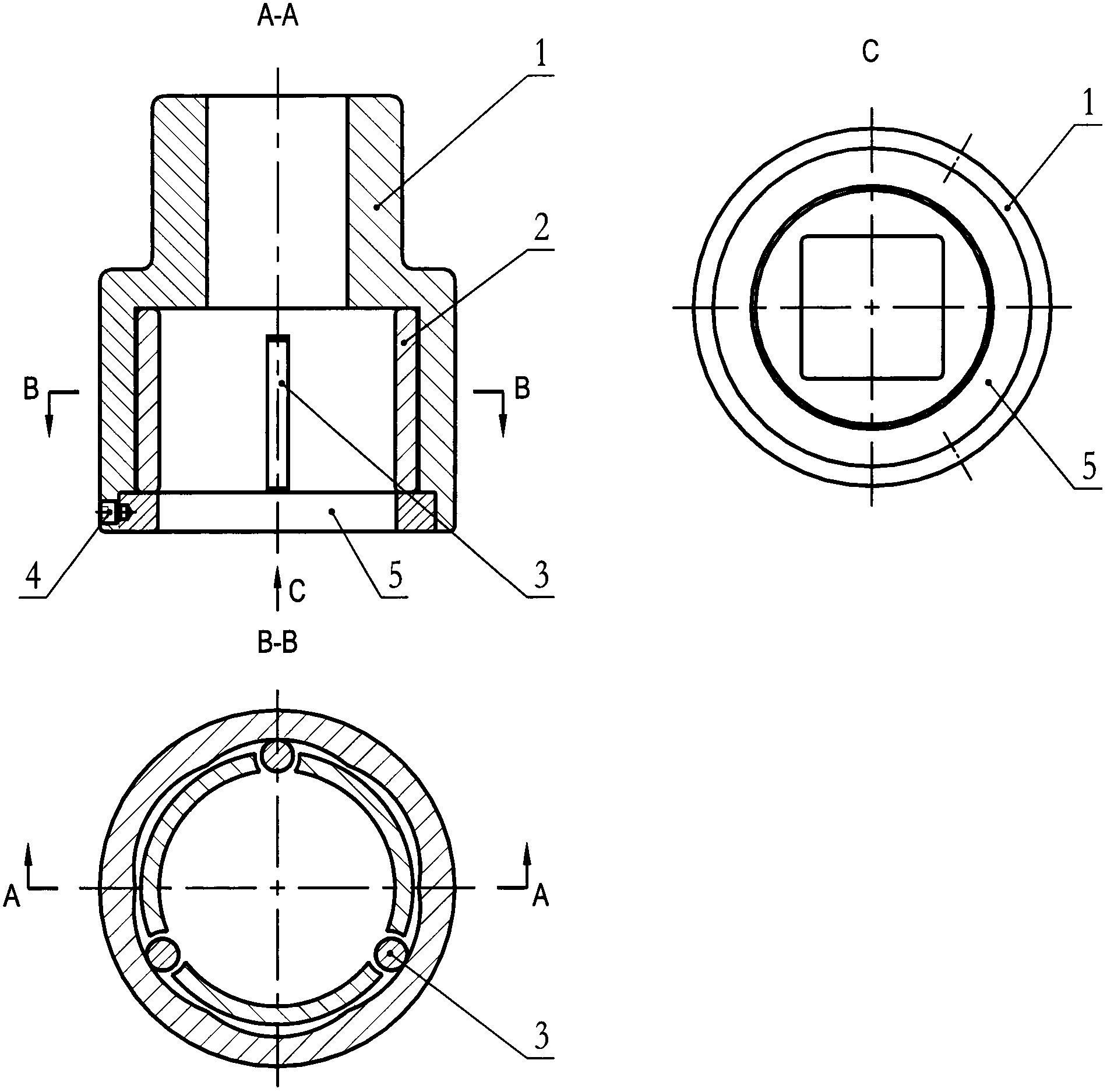

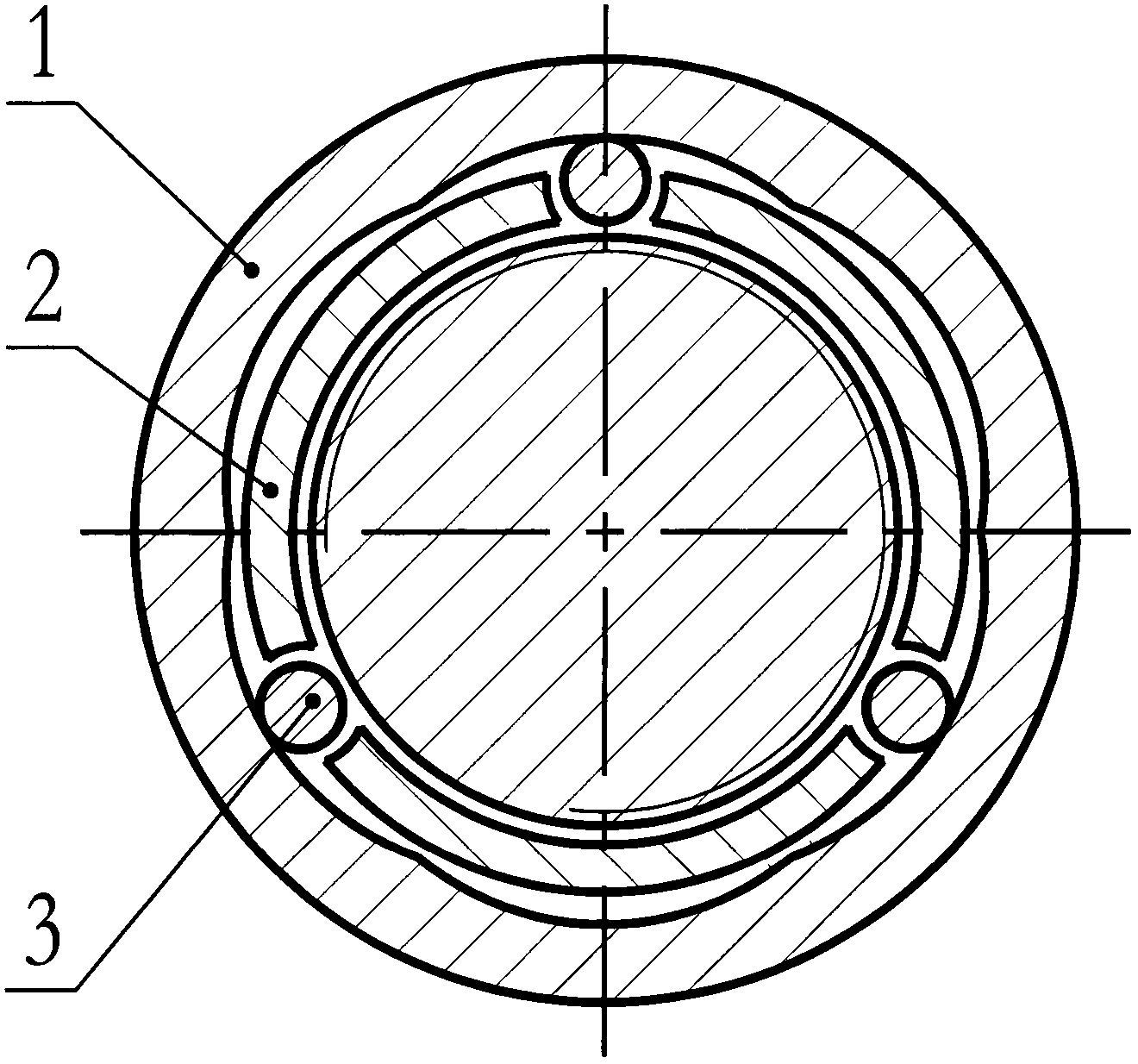

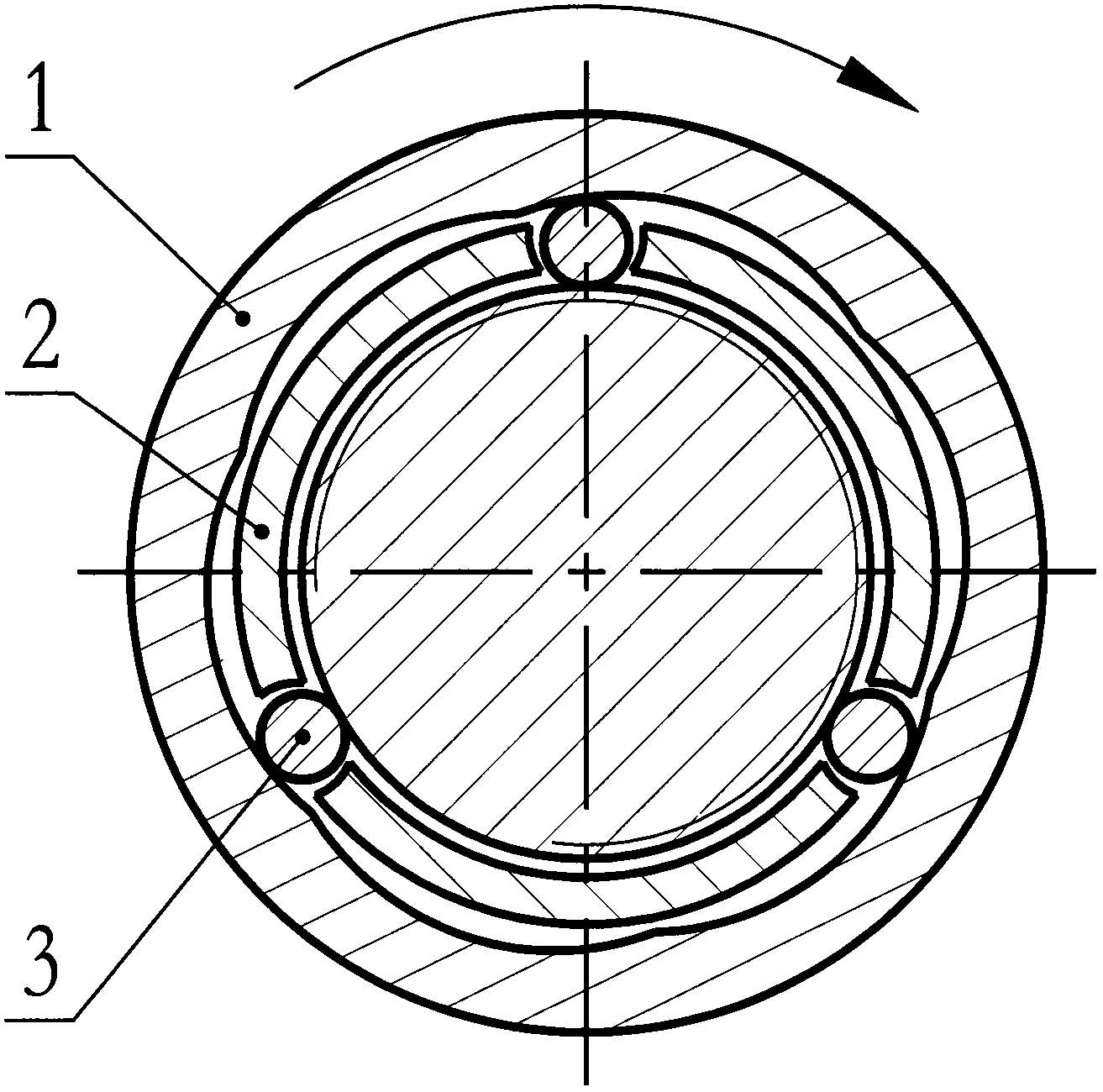

[0017] figure 1 It shows the structure of a plug-in double-ended stud loading and unloading fixture, which consists of a fixture body (1), a cage (2), 3 rollers (3), a retaining ring (5), and a set screw (4 )composition.

[0018] Among them, the upper part of the fixture body (1) has a 0.5-1 inch inner square hole for connection with the square tenon of the electric wrench or pneumatic wrench, and the lower part is formed by an appropriate amount of grooves, and the difference between the highest point and the lowest point of the groove is 0.8-1.5 mm, which is set on the stud during loading and unloading; the cage (2) is placed in the lower cavity of the clamp body (1), which is a cylindrical structure, and its length is 0.3-0.7 mm lower than the cavity depth of the clamp body, and the outer diameter It is 0.3-0.5 mm smaller than the minimum inner diameter of the fixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com