Mechanism used for clamping bearing ring

A bearing ring and clamping plate technology, applied in workpiece clamping devices, chucks, manipulators, etc., can solve the problems affecting the quality of the inner or outer wall of the bearing ring, and the inconvenience of clamping the inner or outer ring of the bearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

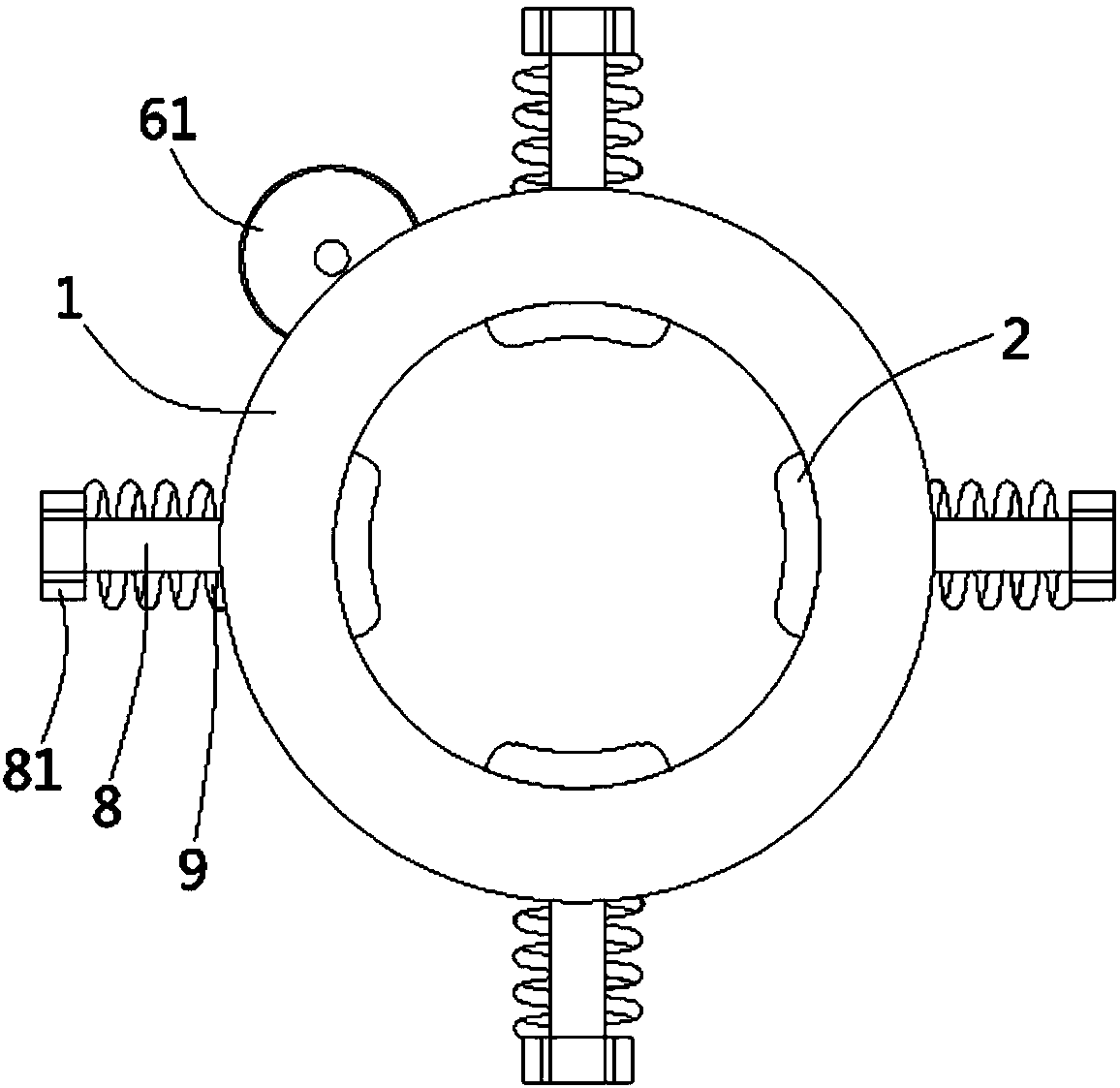

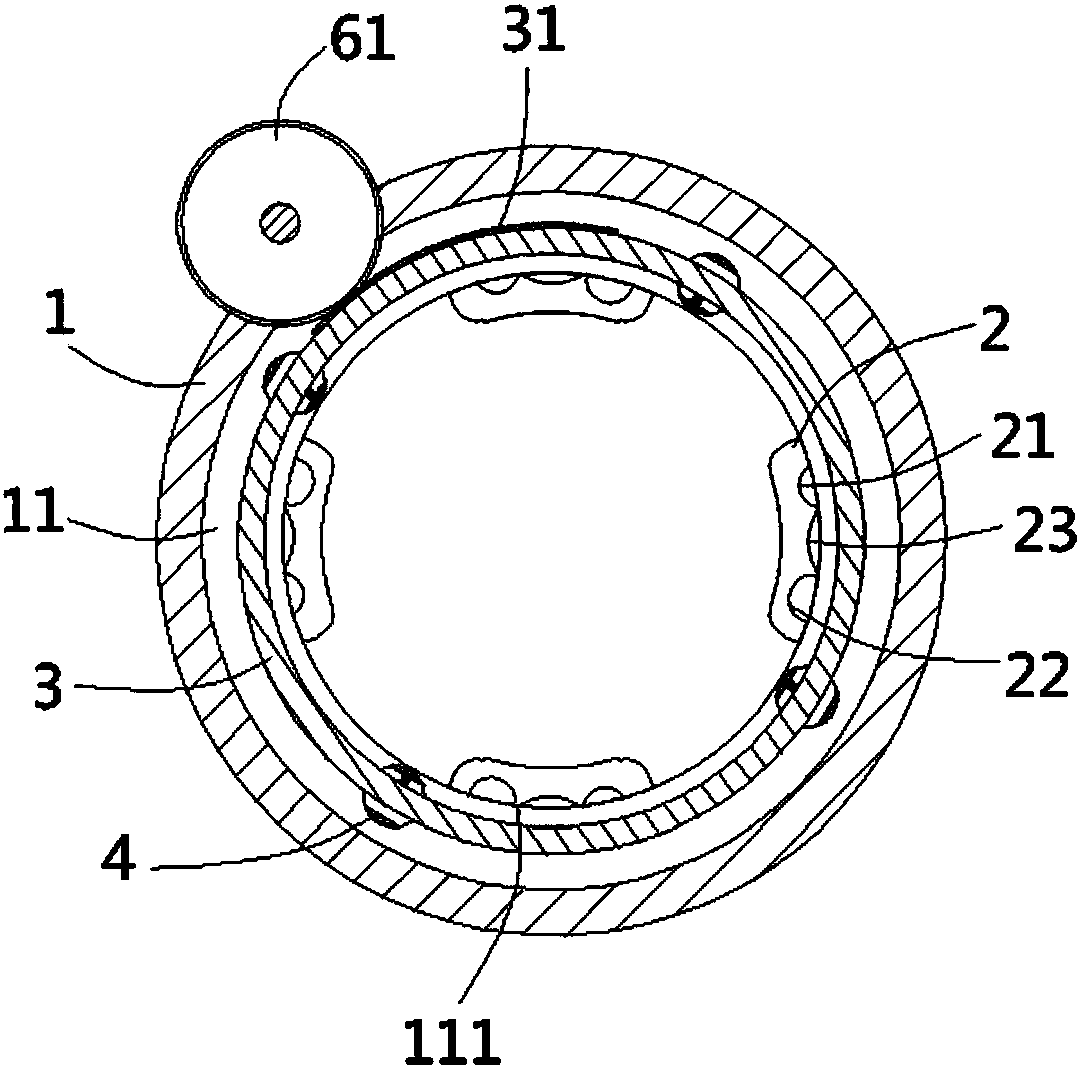

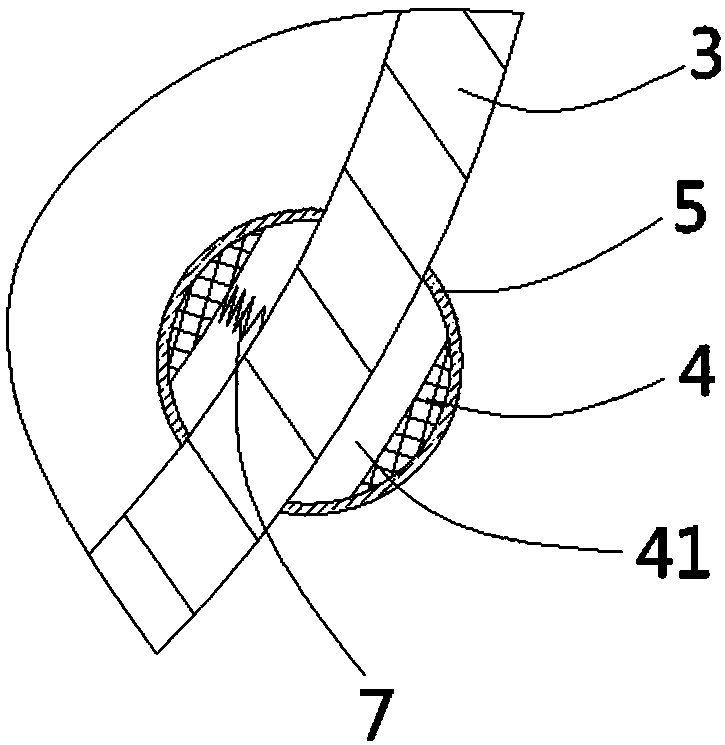

[0023] see Figure 1 to Figure 3 , Figure 5 , a mechanism for clamping bearing rings according to the present invention, including a sleeve 1, the inner wall of the sleeve 1 abuts against a number of arc-shaped clamping plates 2, and the clamping plates in the sleeve 1 There are at least three holding plates 2, and the holding plates 2 are evenly distributed in a ring shape around the central axis of the sleeve 1. The side wall of the holding plate 2 facing the inner wall of the sleeve 1 is formed with a first limiting groove 21 and a second Two limit grooves 22, the first limit groove 21 and the second limit groove 22 are arc-shaped and the depth of the second limit gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com