Graphite negative electrode material of lithium ion battery and preparation method for graphite negative electrode material

A lithium-ion battery, graphite anode technology, applied in battery electrodes, negative electrodes, active material electrodes, etc., can solve the problems of electrolyte absorption capacity, rate performance Coulomb efficiency difficult to achieve application goals, etc., and achieve excellent Coulomb efficiency and cycle life. , The effect of high rate charge and discharge performance improvement and ability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

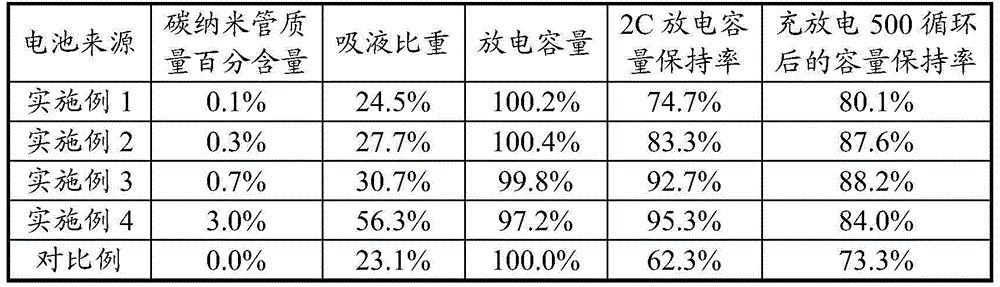

Examples

Embodiment 1

[0030] Preparation of graphite negative electrode material:

[0031] 1) Disperse the carbon nanotubes in deionized water containing 1% by mass of the surfactant hexadecyltrimethylammonium bromide (HTAB), and ultrasonically treat them for 80 minutes to uniformly disperse the carbon nanotubes in the dispersant , the mass percentage of carbon nanotubes in the dispersion is 3%, that is, the required carbon nanotube dispersion is obtained;

[0032] 2) Uniformly mix 20kg of graphite with 0.8kg of the carbon nanotube dispersion obtained in step 1) by kneading and stirring, so that the carbon nanotubes are evenly coated on the graphite surface; then add 16kg of deionized water and stir evenly; control the temperature at 85°C , keep stirring until the deionized water evaporates to dryness;

[0033] 3) vacuum drying the mixture obtained in step 2) at a temperature of 95°C;

[0034] 4) The mixture obtained in step 3) is compacted, calcined at a high temperature of 430° C. for 6 hours, ...

Embodiment 2

[0040] This embodiment adopts the same method as Example 1 to prepare graphite negative electrode material and lithium ion battery, the difference is that the second step of graphite negative electrode material preparation is as follows:

[0041] 2) Uniformly mix 20kg of graphite with 2kg of the carbon nanotube dispersion obtained in step 1) by kneading and stirring, so that the carbon nanotubes are uniformly coated on the graphite surface; then add 15kg of deionized water and stir evenly; control the temperature at 85°C, Keep stirring until the deionized water evaporates to dryness.

[0042] Therefore, in the finally obtained graphite negative electrode material uniformly coated with carbon nanotubes, the mass percentage of carbon nanotubes is 0.3%.

Embodiment 3

[0044] This embodiment adopts the same method as Example 1 to prepare graphite negative electrode material and lithium ion battery, the difference is that the second step of graphite negative electrode material preparation is as follows:

[0045]2) Uniformly mix 20kg of graphite with 5kg of the carbon nanotube dispersion obtained in step 1) by kneading and stirring, so that the carbon nanotubes are uniformly coated on the graphite surface; then add 12kg of ethanol and stir evenly; control the temperature at 85°C and keep stirring until the deionized water evaporates to dryness.

[0046] Therefore, in the finally obtained graphite negative electrode material uniformly coated with carbon nanotubes, the mass percentage of carbon nanotubes is 0.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com