Carbon prebaked anode

A pre-baked anode and carbon technology, applied in the field of aluminum electrolysis, can solve the problems affecting anode resistivity, strength, and low anode bulk density, and achieve the effects of reducing anode resistivity, reducing resistivity, and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

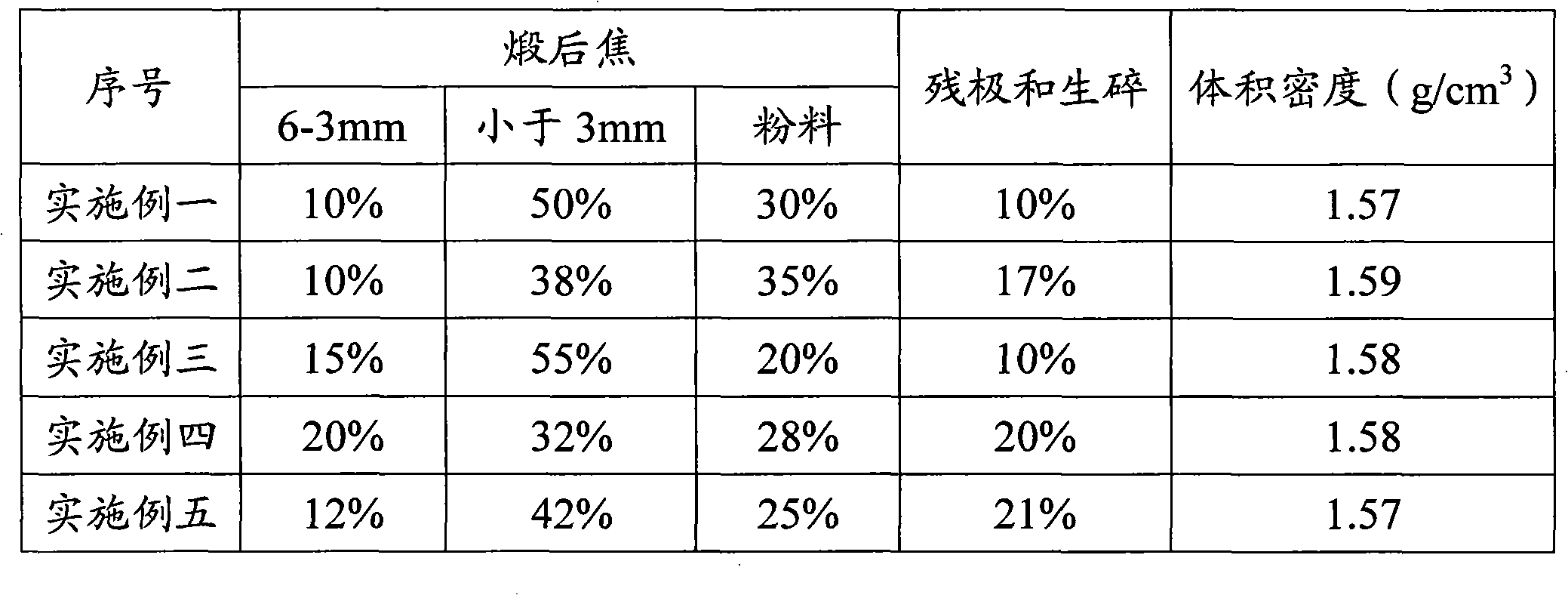

[0033] Weigh 0.3kg of calcined coke with a particle size of 6-3mm, 1.5kg of calcined coke with a particle size of 3-0mm, and 0.9kg of a 200-mesh powder of calcined coke, that is, 10% of the aggregate with a total weight of 3Kg has a particle size of 6- 3mm calcined coke, 50% 3-0mm calcined coke, 30% calcined coke 200 mesh powder and 10% residual electrode, raw crushed, among which, the purity of the powder is not less than 55%, that is, the particle size of the powder The percentage value of the material with a diameter less than 200 mesh (-0.075mm) in the mass of the powder is not less than 55%.

[0034] Pour the above raw materials into a kneader and knead evenly. After 10 minutes, add 0.53 kg of modified asphalt powder, which is 15% of the total weight of aggregate and asphalt. Knead for another 10 minutes, then heat to 150-200 ° C for 40 minutes Then take it out.

[0035] After the paste was left to stand for 1 hour, it was baked to 200°C, and at the same time, the sample...

Embodiment 2

[0043] Weigh 0.3kg of calcined coke with a particle size of 6-3mm, 1.14kg of calcined coke with a particle size of 3-0mm, and 1.05kg of calcined coke with a 200-mesh powder, that is, 10% of the aggregate with a total weight of 3Kg has a particle size of 6- 3mm calcined coke, 38% 3-0mm calcined coke, 35% calcined coke 200 mesh powder and 7% residual electrode, raw crushed, poured into the kneader and kneaded evenly, after 10 minutes, add modified asphalt powder 0.49kg of asphalt, which accounts for 14% of the total weight of aggregate and asphalt, is kneaded for 10 minutes, then heated to 150°C, and taken out after 40 minutes.

[0044] The firing step is as described in Example 1, and the bulk density of the anode sample obtained in this example is detected to be 1.59 g / cm 3 , the resistivity is 49.27μΩ·m.

Embodiment 3

[0046] Weigh 0.45kg of calcined coke with a particle size of 6-3mm, 1.65kg of calcined coke with a particle size of 3-0mm, and 0.6kg of calcined coke with a 200 mesh powder, that is, 15% of aggregates with a total weight of 3Kg have a particle size of 6- 3mm calcined coke, 55% 3-0mm calcined coke, 20% calcined coke 200 mesh powder and 10% residual electrode, raw crushed, poured into the kneader and kneaded evenly, after 10 minutes, add modified asphalt powder 0.51kg, that is, 14.5% of the total weight of pitch, kneaded for another 10 minutes, then heated to 165°C, and taken out after 40 minutes.

[0047] The firing step is as described in Example 1, and the bulk density of the anode sample obtained in this example is detected to be 1.58 g / cm 3 , the resistivity is 49.82μΩ·m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com