Flexible force-sensitive sensor based on silver-embedded nanofibers and preparation method thereof

A nanofiber and nanofiber membrane technology, applied in the field of sensors, can solve the problems of uneven distribution of silver nanoparticles, difficult to obtain spinning precursor liquid, uneven diameter of nanofibers, etc., and achieves superior electrical performance, simple preparation method and distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

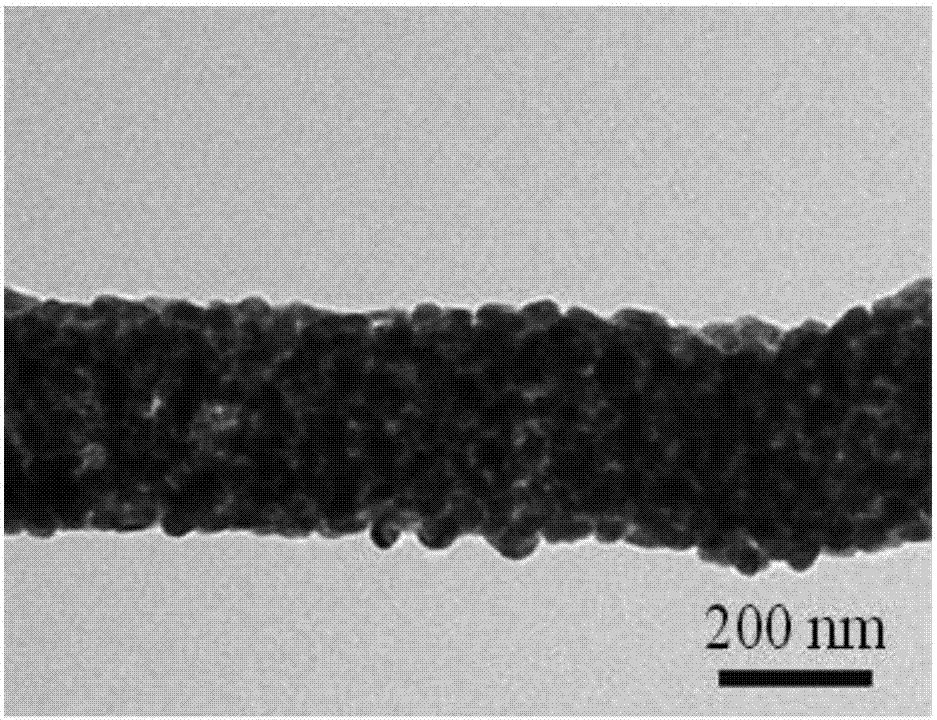

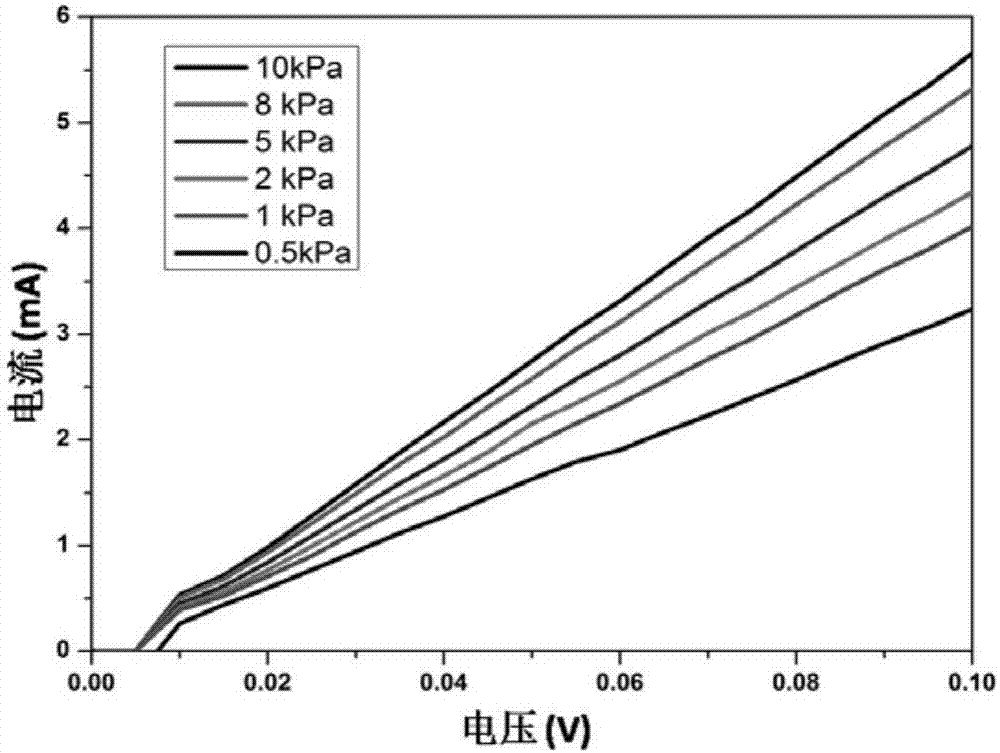

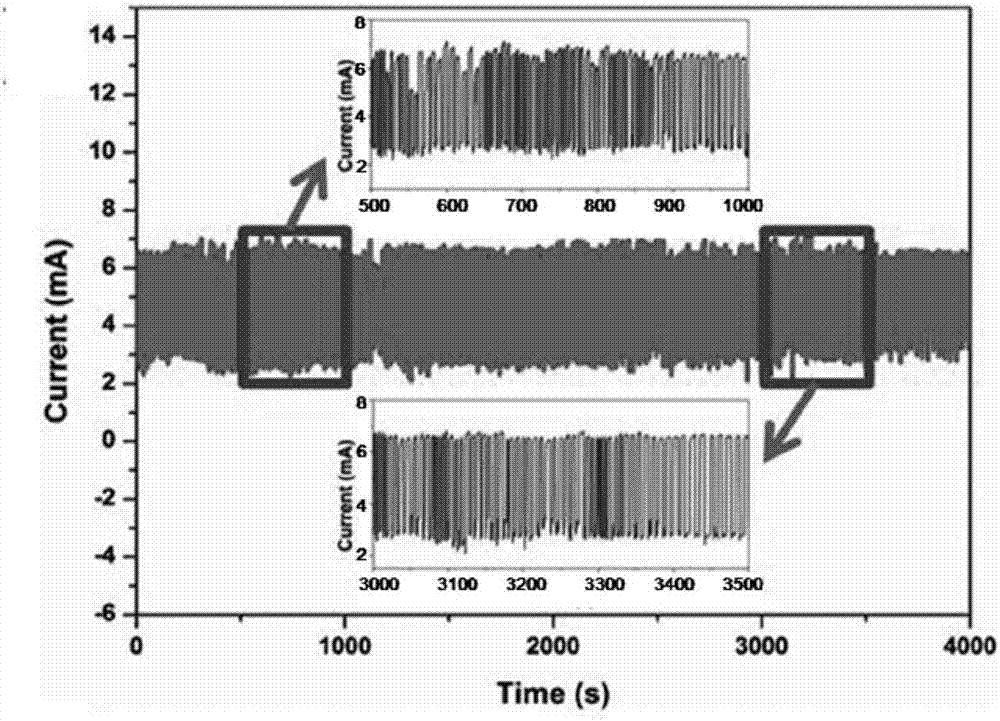

[0031] A flexible force-sensitive sensor based on silver-loaded nanofibers, including a flexible force-sensitive resistor film, the flexible force-sensitive resistor film is connected in series with a power supply and an ammeter, and the flexible force-sensitive resistor film includes a silver-loaded nanofiber film, and Covering the elastic protective film on the upper and lower surfaces of the silver-loaded nanofiber membrane, the two ends of the silver-loaded nanofiber membrane are respectively connected to wires, and the silver-loaded nanofiber membrane is composed of alginic acid / silver nanoparticle composite nanofibers. The described alginic acid / silver nanoparticle composite nanofiber is sodium alginate nanofiber prepared by electrospinning method, and silver alginate nanofiber is obtained through ion exchange, and then reduced silver ion is obtained, and described alginic acid / The inner and outer surfaces of the silver nanoparticle composite nanofiber are uniformly dist...

Embodiment 2

[0039] A flexible force-sensitive sensor based on silver-loaded nanofibers, its structure is similar to the flexible force-sensitive sensor of embodiment 1, the difference is that the preparation method of the flexible force-sensitive sensor comprises the following steps:

[0040] (1) Electrospun sodium alginate nanofiber: at room temperature, weigh 0.64g of sodium alginate powder, add it to the container, then add 0.16g polyethylene oxide PEO, 0.4g triton, 2g dimethylmethylene Sulfone, 36.8g deionized water, stirred at room temperature for 3h to obtain the spinning precursor solution, injected the spinning precursor solution into the electrospinning device, prepared sodium alginate nanofibers by electrospinning, spinning voltage 12kV, spinning The distance is 15cm, the spinning time is 25min, the sodium alginate nanofibers obtained by electrospinning are placed in an oven and dried in an oven at 50°C for 2h, and the obtained fiber membrane is cut into 2×2cm 2 small pieces of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com