Sewing machine thread trimming device and using method thereof

A sewing machine and thread trimming technology, applied in the sewing machine to cut off the thread mechanism, sewing machine components, sewing equipment, etc., can solve the problems of continuous cutting, reduced thread trimming effect, and affecting the work efficiency of staff, so as to maintain sharpness and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

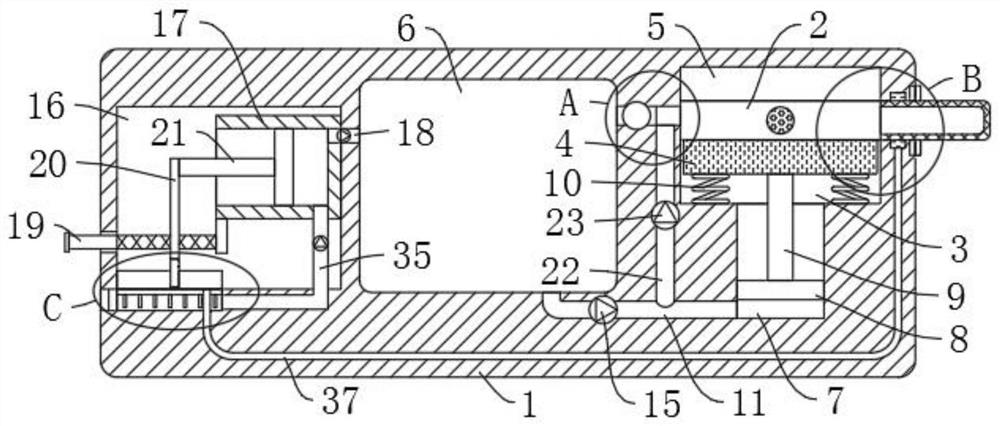

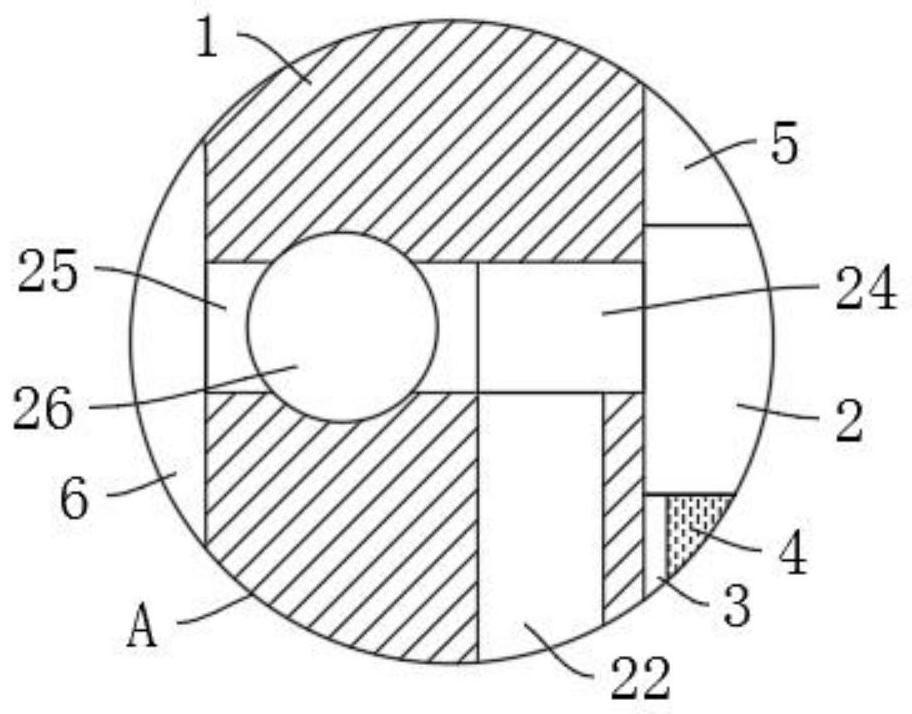

[0040] refer to Figure 1-6, a sewing machine thread trimming device, comprising a device plate 1, the side wall of the device plate 1 is provided with a thread trimming slot 2, the left and right inner walls of the thread trimming slot 2 are provided with a chute 3 and a card slot 5, and the chute 3 is slidingly connected with The blade 4, the device board 1 is provided with an air storage tank 6, the inner wall of the chute 3 is provided with a sliding chamber 7, and the sliding chamber 7 is slidably connected with a piston 8, and the side wall of the piston 8 and the side wall of the blade 4 are connected by a connecting rod 9 fixed connection, the blade 4 and the inner wall of the chute 3 are elastically connected by the return spring 10, the air outlet pipe 11 of the gas storage tank 6 extends into the sliding chamber 7, and the first valve 15 is fixedly installed in the air outlet pipe 11, and the air outlet pipe The end side wall of 11 is fixedly connected with an air r...

Embodiment 2

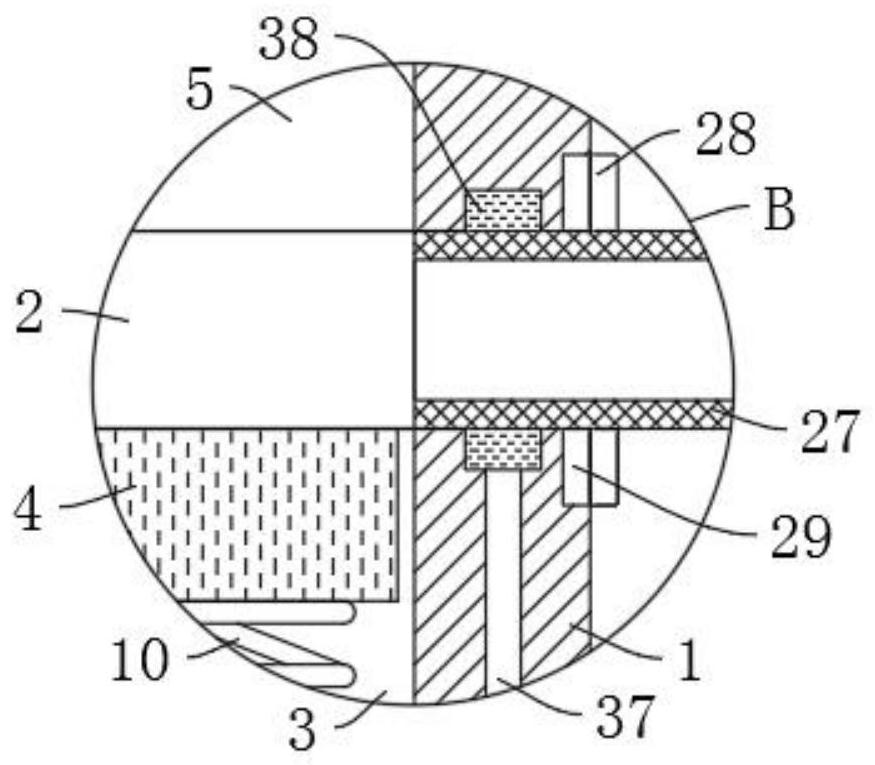

[0042] refer to Figure 5-6 , is basically the same as that of Embodiment 1, and furthermore, the thread pressing mechanism includes a device box 12 fixedly connected to the upper and lower side walls of the blade 4, and the two device boxes 12 are slidably connected with a pressing plate 13 extending to the outer wall, and the pressing plate 13 It is elastically connected with the inner wall of the device box 12 by a tensioning spring 14. When the blade 4 slides in the slot 5, the blade 4 will drive the device box 12 to slide in the direction of the slot 5, and the device box 12 will drive the pressing plate 13 to the direction of the slot 5. Draw-in groove 5 direction slides, and two pressing plates 13 then can be pressed silk thread on the inwall of thread cutting groove 2, and under the effect of tensioning spring 14 elastically hold tight, thereby make blade 4 cut silk thread more conveniently.

[0043] Furthermore, the end of the pressing plate 13 is fixedly connected wi...

Embodiment 3

[0045] refer to figure 1 , is basically the same as Embodiment 1, and furthermore: the inflation mechanism includes an air pump 17 fixedly installed in the device cavity 16, and the inflation tube 18 of the air pump 17 is fixedly connected and communicated with the air storage tank 6, and the side of the air pump 17 The wall is rotatably connected with a reciprocating lead screw 19, the other end of the reciprocating lead screw 19 is fixedly connected with the driving shaft of the sewing machine, the outer wall of the reciprocating lead screw 19 is provided with a lead screw slider 20 cooperating with it, and the side wall of the lead screw slider 20 It is fixedly connected with the end of the push rod 21 of the pump 17. During the operation of the sewing machine, the sewing machine drives the reciprocating screw 19 to rotate through the main shaft, and the reciprocating screw 19 will drive the screw slider 20 to slide back and forth, and the screw slider 20 will Drive the pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com