High-reliability planar bump type packaging method and packaging structure

A technology of planar bump type and packaging method, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc. It can solve the problem of poor contact effect, small pin area, and inability to guarantee the effective gripping area of metal pins, etc. problem, achieve the effect of reducing the missed brush rate, increasing the area, and improving the test UPH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

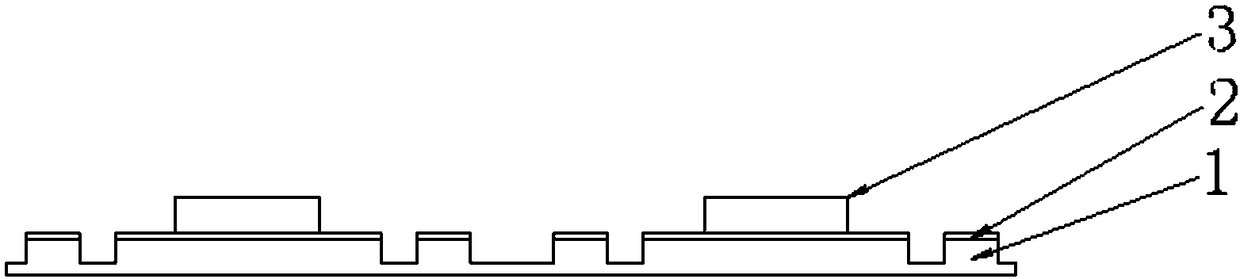

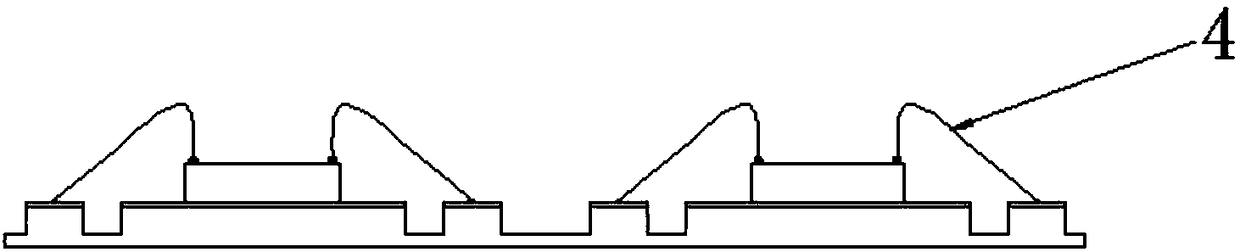

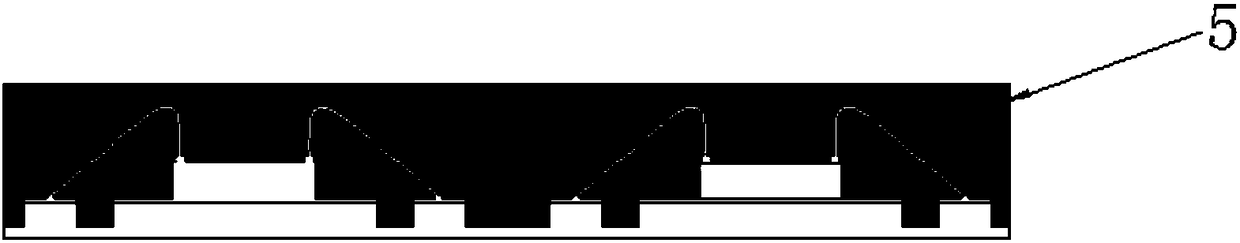

[0065] Such as Figure 1-8 As shown, a high-reliability planar bump packaging method uses a planar bump packaging method to set an ink layer on the redundant metal area etched on the back of the substrate after the etching step on the back of the substrate, and the ink layer 7 covers the surface of the metal area and On the side of the pins of the metal substrate 1 , the pins of the metal substrate 1 protrude from the ink layer 7 . The ink layer 7 can ensure that the short circuit caused by bridging is prevented during the welding process; welding is only performed on the parts that must be welded to avoid waste of solder; reducing copper pollution to the welding tank; preventing external environmental factors such as dust and moisture from causing Insulation deterioration and corrosion; high insulation, making it possible to increase the density of circuits. The protruding ink layer 7, after adding the pin metal layer 8, effectively increases the overall glue-grabbing area, ...

Embodiment 2

[0090] Embodiment 2 is basically the same as Embodiment 1, and furthermore, preferably, step A further includes placing the ink-brushed substrate in a vacuum box for vacuuming. When vacuuming, choose 0.08-0.1MPa, and the time is 5-10min. During the process of brushing ink, because there are air bubbles in the ink, put the substrate after brushing ink in a vacuum box for vacuuming, which can effectively prevent the product The generation of internal air bubbles ensures the quality of the product and prevents the introduction of new defects. And because of the two-step baking steps before and after, the vacuuming step also effectively prevents the cracking and unevenness of the ink layer during baking due to air bubbles during the baking stage, which affects the overall performance, and also prevents the height of the ink from being inconsistent when it shrinks. The protruding height of the pins is inconsistent, which will cause glue brushing defects in the subsequent process an...

Embodiment 3

[0092] Based on the above method, a high-reliability planar bump package structure includes a chip carrier base, a wire-bonding inner pin carrier base, a chip 3, a lead 4 and a plastic package, and the chip carrier base includes a base island and a base island The front metal layer 2 of the wire-bonding inner foot base includes pins and the front metal layer 3 of the pins. There is a metal layer 2 on the connecting rib, and the chip 3 is implanted on the front metal layer 2 of the chip bearing base. 3. The front side and the front side metal layer 2 are respectively connected with the two ends of the metal wires to form a semi-finished package structure. The front side and the outer peripheral edge of the semi-finished package structure form an encapsulation 5, and make the base island and the back of the pin protrude from the surface of the plastic package. The base island and pin surface on the back are plated with pin metal layer 8 , except that the extra metal area on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com